1-26

Getting Started

Laser Safety Information

Laser Safety Information

• Laser Safety Information

The light sources specified by this user guide are classified according to

IEC 60825-1 (2001). The light sources comply with 21 CFR 1040.10 except for deviations pursu-

ant to Laser Notice No. 50, dated 2001-July-26

WARNING - Please pay attention to the following laser safety warnings:

• Under no circumstances look into the end of an optical cable attached to the optical output when

the device is operational. The laser radiation can seriously damage your eyesight.

• Do not enable the laser when there is no fiber attached to the optical output connector.

• The use of optical instruments with this product will increase eye hazard.

• Refer servicing only to qualified and authorized personnel.

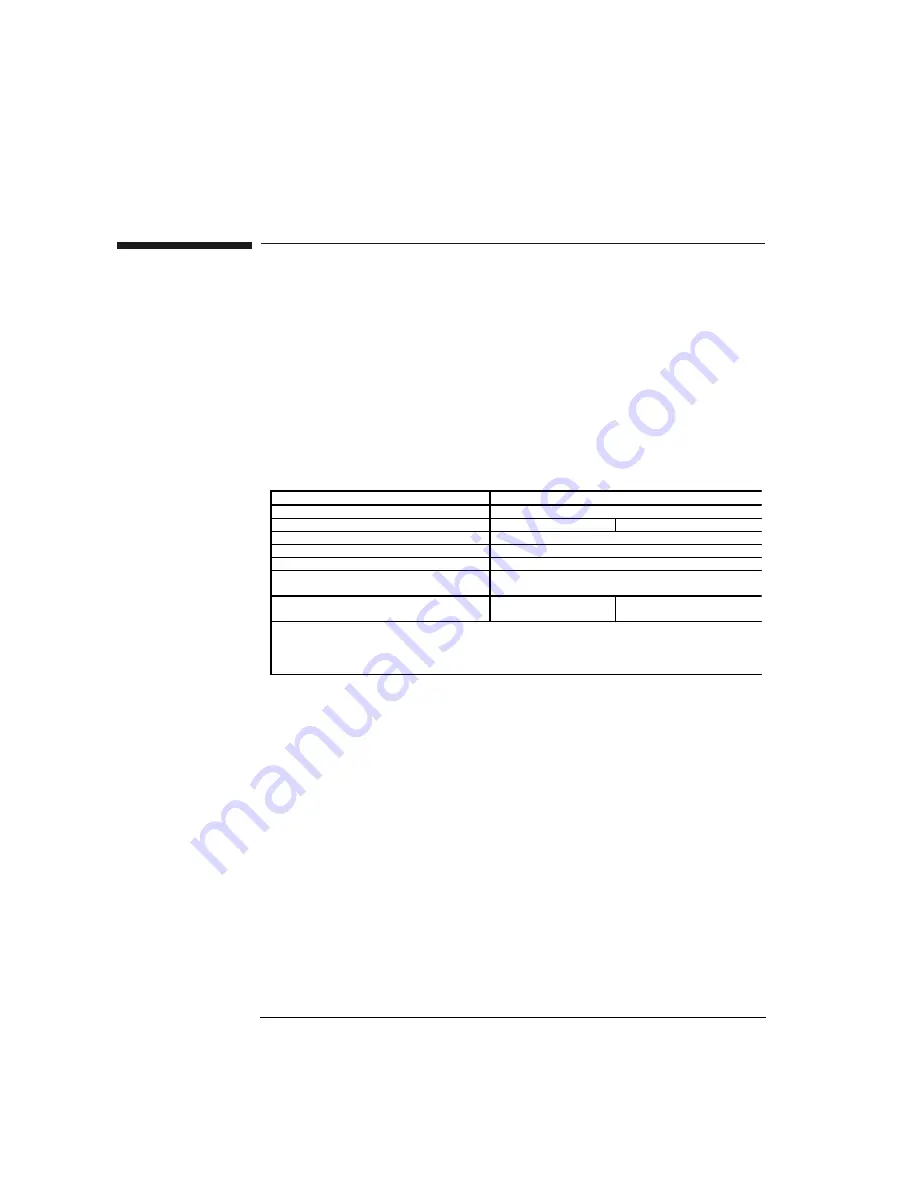

La ser type

E dge em ittin g LED (EE LED )

W a velen gth 1310n m

1550

nm

M a x. CW outpu t pow er *

50

µ W

B eam w a ist diam eter

9 µm

N u m erica l aperture

0.1

La ser class a ccordin g to

IEC 60825-1 (2001)

1

M a x. perm issible

CW ou tpu t pow er **

15,6m W

10m W

*

M a x. CW output pow er m ea n s th e highest possible optica l CW pow er tha t th e laser source ca n

produ ce a t its ou tput.

**

M a x. perm issible CW ou tput pow er is th e h igh est optica l pow er th a t is perm itted w ith in the

a ppropria te IEC la ser cla ss.

Summary of Contents for 8614 B Series

Page 1: ...Agilent 8614xB Series Optical Spectrum Analyzer User s Guide ...

Page 12: ...1 4 Getting Started Product Overview Agilent 8614xB Front and Rear Panels ...

Page 13: ...1 5 Getting Started Product Overview ...

Page 15: ...1 7 Getting Started Product Overview Figure 1 2 Display Annotations ...

Page 26: ...1 18 Getting Started The Softkey Panels ...

Page 31: ...1 23 Getting Started The Softkey Panels The Systems Menus continued ...

Page 40: ...1 32 Getting Started Product Options and Accessories ...

Page 75: ...3 Function Reference ...

Page 186: ...4 16 Remote Front Panel Operation Remote Front Panel ...

Page 226: ...6 2 Maintenance Changing the Printer Paper Changing the Printer Paper ...

Page 271: ......