Y

O

Coil

Drive

Check

with

Oscilloscope

Note

Use

the

large

extender

board

for

easy

access

to

the

voltage

points

.

The

extender

board

is

included

with

the

HP

8753

T

ool

Kit.

See

the

\Replaceable

P

arts"

chapter

for

part

numbers

and

ordering

information.

1.

Connect

oscilloscope

probes

to

A11P1-1

and

A11P1-2.

The

Y

O

coil

drive

signal

is

actually

two

signals

whose

voltage

dierence

drives

the

coil.

2.

Press

4

PRESET

5

4

SYSTEM

5

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

SERVICE

MENU

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

SERVICE

MODES

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

SOURCE

PLL

OFF

to

operate

the

analyzer

in

a

swept

open

loop

mode

.

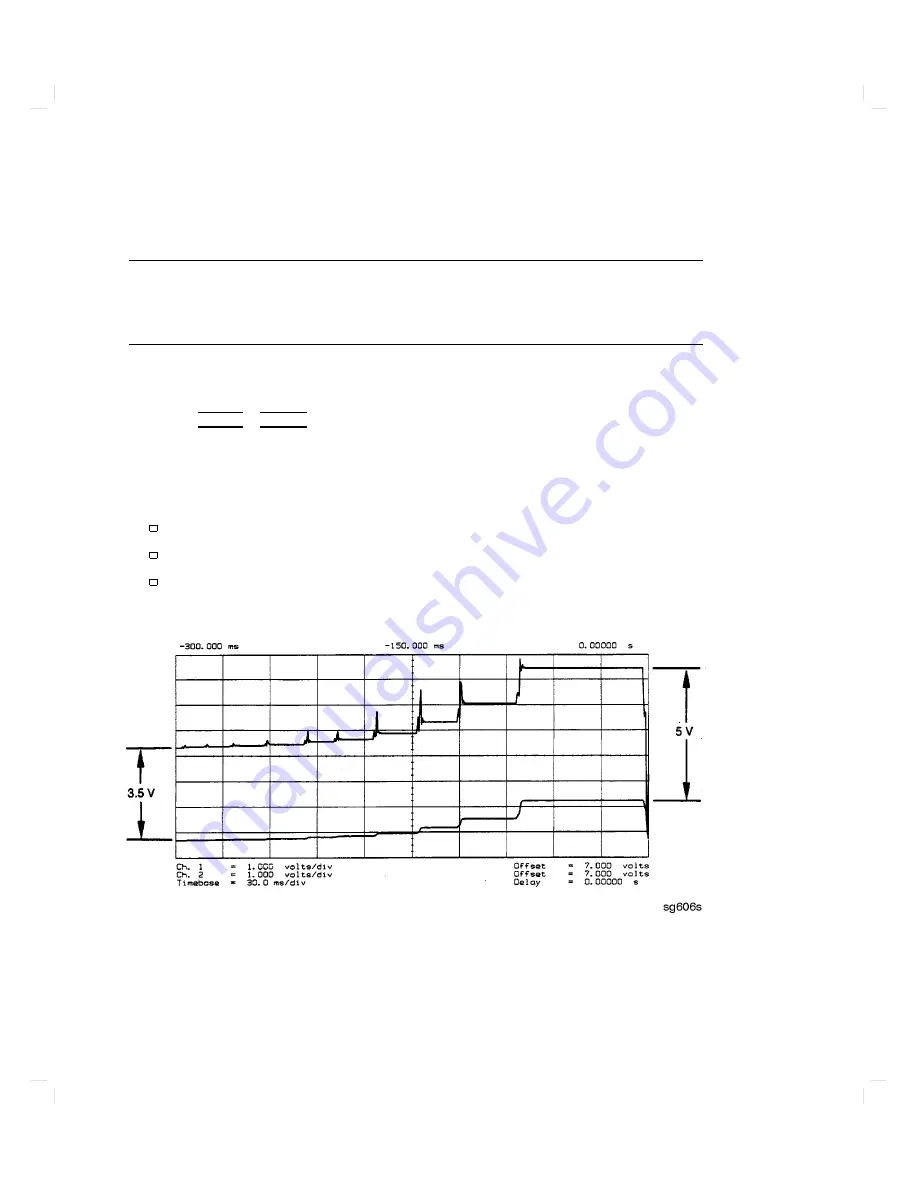

3.

Monitor

the

two

Y

O

coil

drive

lines

.

In

source

tune

mode

the

voltage

dierence

should

vary

from

approximately

3.5

to

5.0

volts

as

shown

in

Figure

7-7.

If

the

voltages

are

incorrect,

replace

the

faulty

A11

assembly

.

If

the

voltages

are

correct,

replace

the

faulty

A3

source

assembly

.

If

neither

the

A11,

nor

the

A3

assembly

is

faulty

,

continue

with

the

next

check.

Figure

7-7.

Y

O0

and

Y

O+

Coil

Drive

V

oltage

Dierences

with

SOURCE

PLL

OFF

7-12

Source

T

roubleshooting

Summary of Contents for 8752C

Page 22: ...Before Applying Power 15 6 Servicing 15 6 Index Contents 16 ...

Page 38: ......

Page 43: ...Figure 2 1 Measurement Uncertainty Window System Veri cation and Performance Tests 2 5 ...

Page 116: ......

Page 122: ...Figure 3 1 Location of Major Assemblies 3 6 Adjustments and Correction Constants ...

Page 176: ......

Page 192: ...4 16 Start Troubleshooting Here ...

Page 193: ......

Page 195: ...Figure 4 7 HP 8752C Overall Block Diagram 3 of 4 Option 006 4 20 Start Troubleshooting Here ...

Page 197: ......

Page 221: ...5 24 Power Supply Troubleshooting ...

Page 222: ......

Page 271: ...Figure 7 21 A14 Generated Digital Control Signals Source Troubleshooting 7 31 ...

Page 302: ......

Page 366: ......

Page 378: ...Figure 11 4 Typical ED Re ection Test Port 11 12 Error Terms ...

Page 380: ...Figure 11 5 Typical ES Re ection Test Port 11 14 Error Terms ...

Page 382: ...Figure 11 6 Typical ER Re ection Test Port 11 16 Error Terms ...

Page 386: ...Figure 11 9 Typical ET 11 20 Error Terms ...

Page 407: ...Figure 12 5 High Band Operation of the Source Theory of Operation 12 21 ...

Page 410: ...Figure 12 6 Receiver Functional Group standard and Option 003 12 24 Theory of Operation ...

Page 411: ...Figure 12 7 Receiver Functional Group Option 003 and 004 Theory of Operation 12 25 ...

Page 412: ...Figure 12 8 Receiver Functional Group Option 006 12 26 Theory of Operation ...

Page 413: ...Figure 12 9 Receiver Functional Group Option 004 and 006 Theory of Operation 12 27 ...

Page 416: ......

Page 419: ...Figure 13 1 Module Exchange Procedure Replaceable Parts 13 3 ...

Page 423: ...Major Assemblies Replaceable Parts 13 7 ...

Page 425: ...Front Panel Assemblies Replaceable Parts 13 9 ...

Page 427: ...Rear Panel Assemblies Replaceable Parts 13 11 ...

Page 429: ...Cables Top View Replaceable Parts 13 13 ...

Page 431: ...Front Panel Cables and Attaching Hardware Replaceable Parts 13 15 ...

Page 433: ...Rear Panel Cables and Attaching Hardware Replaceable Parts 13 17 ...

Page 435: ...Source and Sampler Parts Standard and Option 003 Replaceable Parts 13 19 ...

Page 437: ...Source and Sampler Parts Option 004 006 Replaceable Parts 13 21 ...

Page 439: ...Source and Sampler Parts Options 004 and 003 004 Replaceable Parts 13 23 ...

Page 441: ...Source and Sampler Parts Option 006 Replaceable Parts 13 25 ...

Page 443: ...Display Bezel Assembly Replaceable Parts 13 27 ...

Page 445: ...Chassis Parts Replaceable Parts 13 29 ...

Page 447: ...Top View of Attaching Hardware and Post Regulator Fuses Replaceable Parts 13 31 ...

Page 449: ...Bottom View of Attaching Hardware Replaceable Parts 13 33 ...

Page 488: ......