9-6

Chapter 9

Accessories Troubleshooting

Inspect the Error Terms

Cable Test

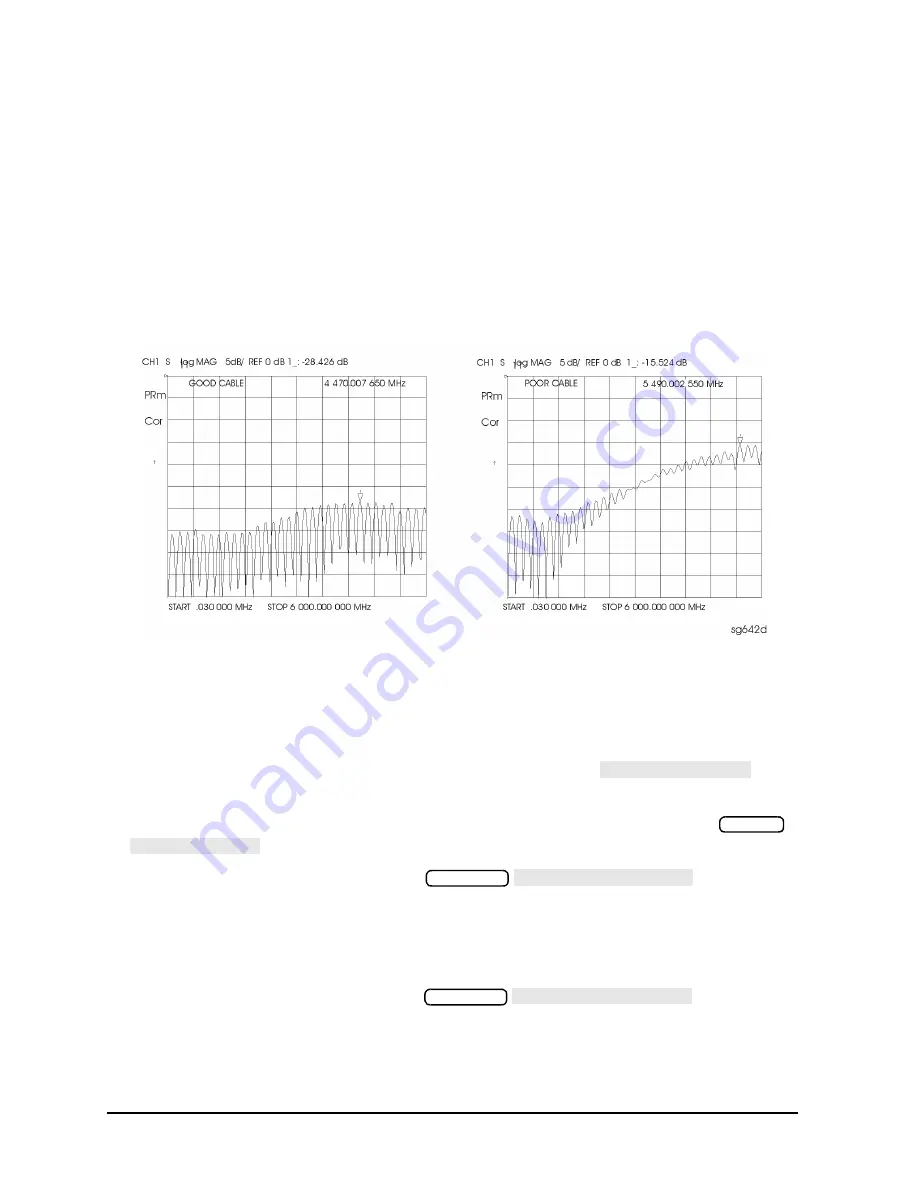

The load match error term is a good indicator of cable problems. You can further verify a

faulty cable by measuring the reflection of the cable. Perform an S11 1-port calibration

directly at port 1 (no cables). Then connect the suspect cable to port 1 and terminate the

open end in 50 ohms.

shows the return loss trace of a good (left side) and faulty (right side) cable.

Note that the important characteristic of a cable trace is its level (the good cable trace is

much lower) not its regularity. Refer to the cable manual for return loss specifications.

Figure 9-1

Typical Return Loss Traces of Good and Poor Cables

Verify Shorts and Opens

Substitute a known good short and open of the same connector type and sex as the short

and open in question. If the devices are not from one of the standard calibration kits, refer

to your analyzer’s user’s guide for information on how to use the

function. Set aside the short and open that are causing the problem.

1. Perform an S11 1-port calibration using the good short and open. Then press

to view the devices in Smith chart format.

2. Connect the good short to port 1. Press

and turn the

front panel knob to enter enough electrical delay so that the trace appears as a dot at

the left side of the circle. (See

a, left.)

Replace the good short with the questionable short at port 1. The trace of the

questionable short should appear very similar to the known good short.

3. Connect the good open to port 1. Press

and turn the

front panel knob to enter enough electrical delay so that the trace appears as a dot at

the right side of the circle. (See

b, right.)

MODIFY CAL KIT

Format

SMITH CHART

Scale Ref

ELECTRICAL DELAY

Scale Ref

ELECTRICAL DELAY

Summary of Contents for 8753ES

Page 14: ...Contents xiv Contents ...

Page 15: ...1 1 1 Service Equipment and Analyzer Options ...

Page 26: ...1 12 Chapter1 Service Equipment and Analyzer Options Service and Support Options ...

Page 27: ...2 1 2 System Verification and Performance Tests ...

Page 203: ...3 1 3 Adjustments and Correction Constants ...

Page 262: ...3 60 Chapter3 Adjustments and Correction Constants Sequences for Mechanical Adjustments ...

Page 263: ...4 1 4 Start Troubleshooting Here ...

Page 297: ...5 1 5 Power Supply Troubleshooting ...

Page 317: ......

Page 318: ...6 1 6 Digital Control Troubleshooting ...

Page 337: ...6 20 Chapter6 Digital Control Troubleshooting GPIB Failures ...

Page 338: ...7 1 7 Source Troubleshooting ...

Page 369: ...7 32 Chapter7 Source Troubleshooting Source Group Troubleshooting Appendix ...

Page 370: ...8 1 8 Receiver Troubleshooting ...

Page 381: ...8 12 Chapter8 Receiver Troubleshooting Troubleshooting When One or More Inputs Look Good ...

Page 382: ...9 1 9 Accessories Troubleshooting ...

Page 389: ...9 8 Chapter9 Accessories Troubleshooting Inspect the Error Terms ...

Page 390: ...10 1 10 Service Key Menus and Error Messages ...

Page 439: ...10 50 Chapter10 Service Key Menus and Error Messages Error Messages ...

Page 440: ...11 1 11 Error Terms ...

Page 451: ...11 12 Chapter11 Error Terms Error Correction ...

Page 452: ...12 1 12 Theory of Operation ...

Page 482: ...13 1 13 Replaceable Parts ...

Page 487: ...13 6 Chapter13 Replaceable Parts Ordering Information Figure 13 1 Module Exchange Procedure ...

Page 500: ...Chapter 13 13 19 Replaceable Parts Replaceable Part Listings Figure 13 7 8753ET Cables Top ...

Page 502: ...Chapter 13 13 21 Replaceable Parts Replaceable Part Listings Figure 13 8 8753ES Cables Top ...

Page 512: ...Chapter 13 13 31 Replaceable Parts Replaceable Part Listings Figure 13 13 8753ES Cables Front ...

Page 544: ...14 1 14 Assembly Replacement and Post Repair Procedures ...

Page 550: ...Chapter 14 14 7 Assembly Replacement and Post Repair Procedures Covers Figure 14 2 Covers ...

Page 597: ...14 54 Chapter14 Assembly Replacement and Post Repair Procedures Post Repair Procedures ...