12-6

Chapter 12

Theory of Operation

Power Supply Theory

Power Supply Theory

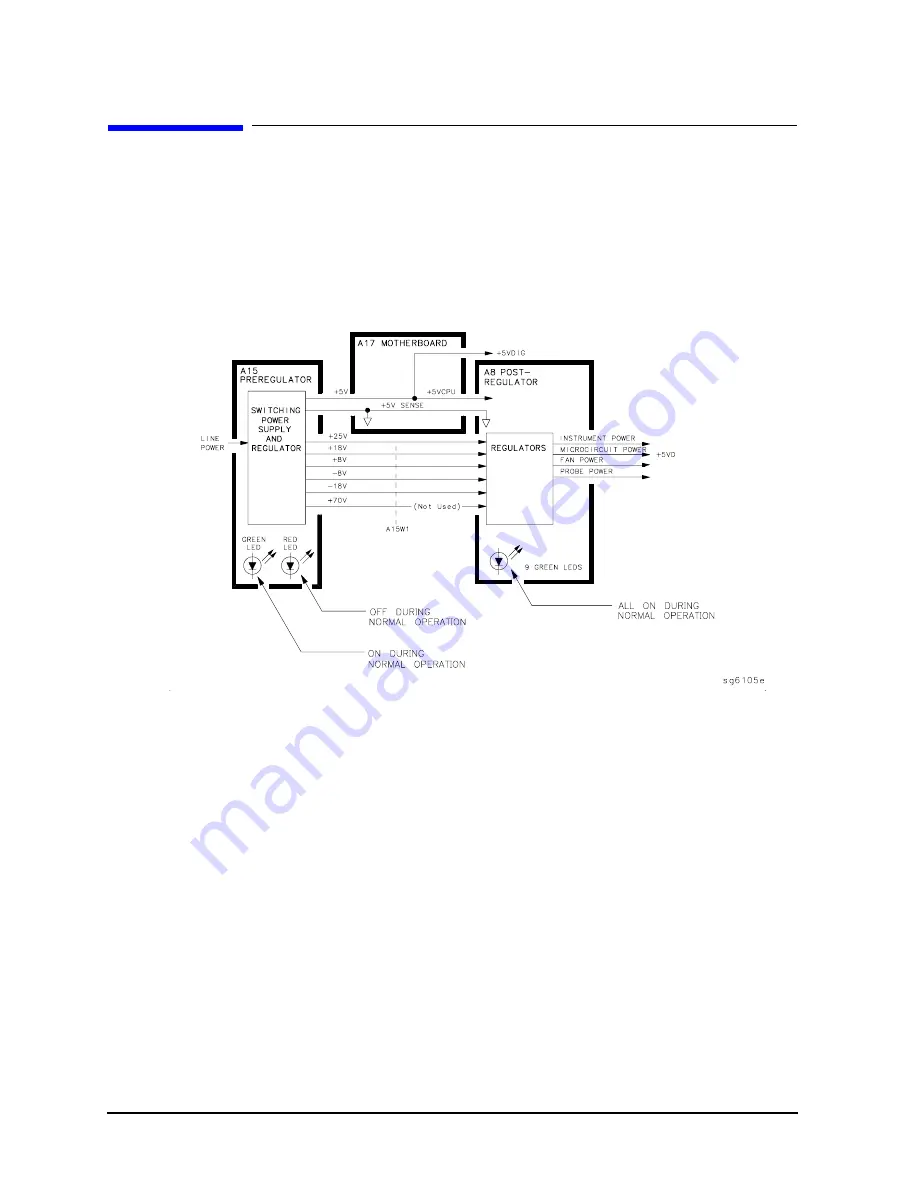

The power supply functional group consists of the A15 preregulator and the A8 post

regulator. These two assemblies comprise a switching power supply that provides

regulated DC voltages to power all assemblies in the analyzer. The A15 preregulator is

enclosed in a casting at the rear of the instrument. It is connected to the A8 post regulator

by a wire bus A15W1.

is a simplified block diagram of the power supply group.

Figure 12-2

Power Supply Functional Group, Simplified Block Diagram

A15 Preregulator

The A15 preregulator steps down and rectifies the line voltage. It provides a fully

reg5 V digital supply, and several preregulated voltages that go to the A8 post

regulator assembly for additional regulation.

The A15 preregulator assembly includes the line power module, a 60 kHz switching

preregulator, and overvoltage protection for the +5 V digital supply. It provides LEDs,

visible from the rear of the instrument, to indicate either normal or shutdown status.

Line Power Module

The line power module includes the line power switch, voltage selector switch, and main

fuse. The line power switch is activated from the front panel. The voltage selector switch,

accessible at the rear panel, adapts the analyzer to local line voltages of approximately

115 V or 230 V (with 350 VA maximum). The main fuse, which protects the input side of

the preregulator against drawing too much line current, is also accessible at the rear

panel. Refer to your analyzer’s installation and quick start guide for line voltage tolerances

and other power considerations. Refer to

Summary of Contents for 8753ES

Page 14: ...Contents xiv Contents ...

Page 15: ...1 1 1 Service Equipment and Analyzer Options ...

Page 26: ...1 12 Chapter1 Service Equipment and Analyzer Options Service and Support Options ...

Page 27: ...2 1 2 System Verification and Performance Tests ...

Page 203: ...3 1 3 Adjustments and Correction Constants ...

Page 262: ...3 60 Chapter3 Adjustments and Correction Constants Sequences for Mechanical Adjustments ...

Page 263: ...4 1 4 Start Troubleshooting Here ...

Page 297: ...5 1 5 Power Supply Troubleshooting ...

Page 317: ......

Page 318: ...6 1 6 Digital Control Troubleshooting ...

Page 337: ...6 20 Chapter6 Digital Control Troubleshooting GPIB Failures ...

Page 338: ...7 1 7 Source Troubleshooting ...

Page 369: ...7 32 Chapter7 Source Troubleshooting Source Group Troubleshooting Appendix ...

Page 370: ...8 1 8 Receiver Troubleshooting ...

Page 381: ...8 12 Chapter8 Receiver Troubleshooting Troubleshooting When One or More Inputs Look Good ...

Page 382: ...9 1 9 Accessories Troubleshooting ...

Page 389: ...9 8 Chapter9 Accessories Troubleshooting Inspect the Error Terms ...

Page 390: ...10 1 10 Service Key Menus and Error Messages ...

Page 439: ...10 50 Chapter10 Service Key Menus and Error Messages Error Messages ...

Page 440: ...11 1 11 Error Terms ...

Page 451: ...11 12 Chapter11 Error Terms Error Correction ...

Page 452: ...12 1 12 Theory of Operation ...

Page 482: ...13 1 13 Replaceable Parts ...

Page 487: ...13 6 Chapter13 Replaceable Parts Ordering Information Figure 13 1 Module Exchange Procedure ...

Page 500: ...Chapter 13 13 19 Replaceable Parts Replaceable Part Listings Figure 13 7 8753ET Cables Top ...

Page 502: ...Chapter 13 13 21 Replaceable Parts Replaceable Part Listings Figure 13 8 8753ES Cables Top ...

Page 512: ...Chapter 13 13 31 Replaceable Parts Replaceable Part Listings Figure 13 13 8753ES Cables Front ...

Page 544: ...14 1 14 Assembly Replacement and Post Repair Procedures ...

Page 550: ...Chapter 14 14 7 Assembly Replacement and Post Repair Procedures Covers Figure 14 2 Covers ...

Page 597: ...14 54 Chapter14 Assembly Replacement and Post Repair Procedures Post Repair Procedures ...