7-20

Chapter 7

Source Troubleshooting

Phase Lock Error

A13/A14 Fractional-N Check

Use the analog bus or an oscilloscope to check the A14 VCO’s ability to sweep from 30 MHz

to 60 MHz. The faster analog bus method should suffice unless problems are detected.

Fractional-N Check with Analog Bus

1. Press

to switch on the analog bus and the fractional-N

counter.

2. Press

to set the analyzer to CW mode.

3. Set the instrument as indicated in

and see whether the VCO generates the

frequencies listed.

4. Check the counter reading at the frequencies indicated.

• If the readings are within the limits specified, the probability is greater than 90%

that the fractional-N assemblies are functional. Either skip ahead to the

, or perform the more conclusive

described next.

• If the readings fail the specified limits, perform the

A14 VCO Range Check with Oscilloscope

1. Remove the W9 HI OUT cable (A14J1 to A7) from the A7 assembly and connect it to an

oscilloscope set for 50 ohm input impedance. Switch on the analyzer.

2. Press

to

activate the FRACN TUNE service mode. See

Chapter 10 , “Service Key Menus and

for more information on the FRACN TUNE mode.

3. Vary the fractional-N VCO frequency with the front panel knob and check the signal

with the oscilloscope. The waveform should resemble

, and

If the fractional-N output signals are correct, continue source troubleshooting by

skipping ahead to

“A7 Pulse Generator Check” on page 7-25

.

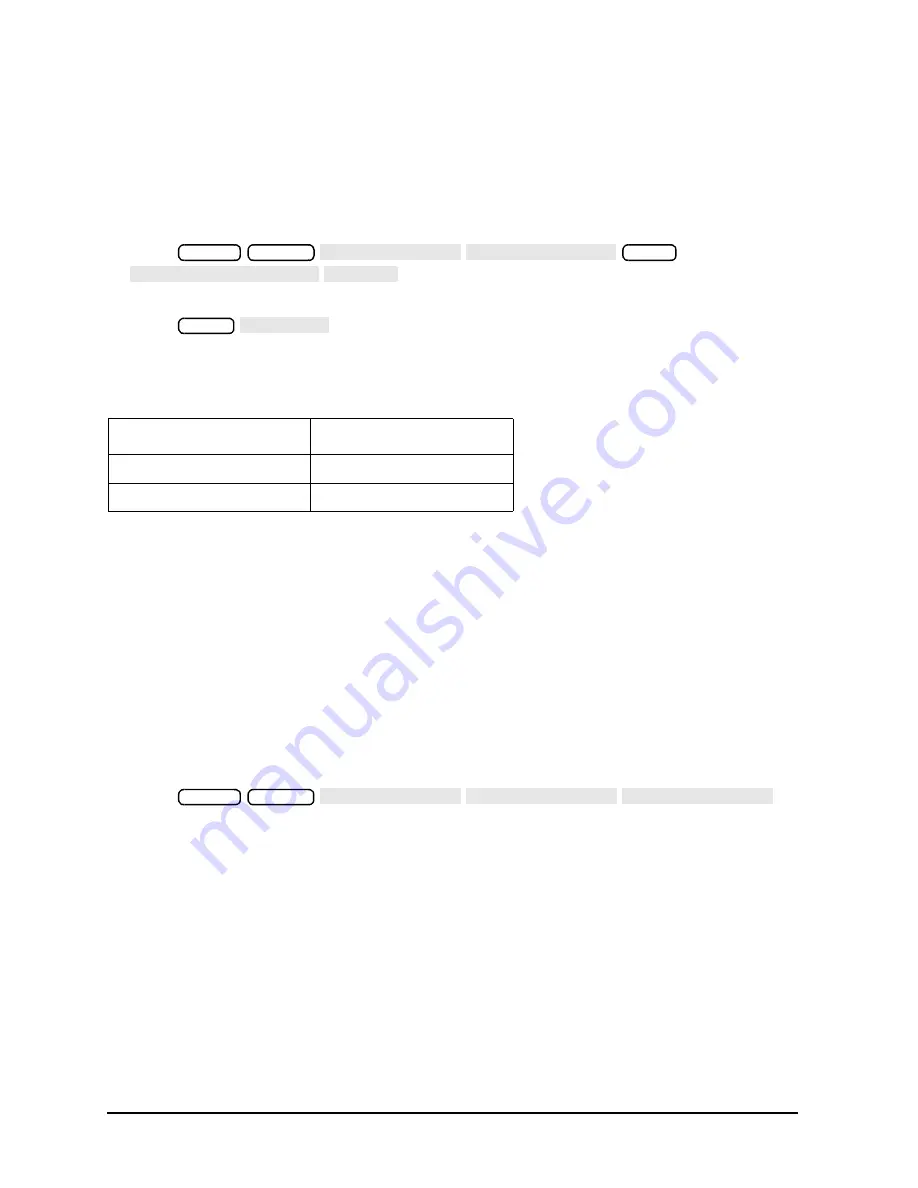

Table 7-5

VCO Range Check Frequencies

Instrument Setting

Counter Reading

31 MHz

30

±

0.030 MHz

60.999999 MHz

60

±

0.060 MHz

Preset

System

SERVICE MENU ANALOG BUS ON

Meas

ANALOG IN Aux Input FRAC N

Menu

CW FREQ

Preset

System

SERVICE MENU SERVICE MODES FRACN TUNE ON

Summary of Contents for 8753ES

Page 14: ...Contents xiv Contents ...

Page 15: ...1 1 1 Service Equipment and Analyzer Options ...

Page 26: ...1 12 Chapter1 Service Equipment and Analyzer Options Service and Support Options ...

Page 27: ...2 1 2 System Verification and Performance Tests ...

Page 203: ...3 1 3 Adjustments and Correction Constants ...

Page 262: ...3 60 Chapter3 Adjustments and Correction Constants Sequences for Mechanical Adjustments ...

Page 263: ...4 1 4 Start Troubleshooting Here ...

Page 297: ...5 1 5 Power Supply Troubleshooting ...

Page 317: ......

Page 318: ...6 1 6 Digital Control Troubleshooting ...

Page 337: ...6 20 Chapter6 Digital Control Troubleshooting GPIB Failures ...

Page 338: ...7 1 7 Source Troubleshooting ...

Page 369: ...7 32 Chapter7 Source Troubleshooting Source Group Troubleshooting Appendix ...

Page 370: ...8 1 8 Receiver Troubleshooting ...

Page 381: ...8 12 Chapter8 Receiver Troubleshooting Troubleshooting When One or More Inputs Look Good ...

Page 382: ...9 1 9 Accessories Troubleshooting ...

Page 389: ...9 8 Chapter9 Accessories Troubleshooting Inspect the Error Terms ...

Page 390: ...10 1 10 Service Key Menus and Error Messages ...

Page 439: ...10 50 Chapter10 Service Key Menus and Error Messages Error Messages ...

Page 440: ...11 1 11 Error Terms ...

Page 451: ...11 12 Chapter11 Error Terms Error Correction ...

Page 452: ...12 1 12 Theory of Operation ...

Page 482: ...13 1 13 Replaceable Parts ...

Page 487: ...13 6 Chapter13 Replaceable Parts Ordering Information Figure 13 1 Module Exchange Procedure ...

Page 500: ...Chapter 13 13 19 Replaceable Parts Replaceable Part Listings Figure 13 7 8753ET Cables Top ...

Page 502: ...Chapter 13 13 21 Replaceable Parts Replaceable Part Listings Figure 13 8 8753ES Cables Top ...

Page 512: ...Chapter 13 13 31 Replaceable Parts Replaceable Part Listings Figure 13 13 8753ES Cables Front ...

Page 544: ...14 1 14 Assembly Replacement and Post Repair Procedures ...

Page 550: ...Chapter 14 14 7 Assembly Replacement and Post Repair Procedures Covers Figure 14 2 Covers ...

Page 597: ...14 54 Chapter14 Assembly Replacement and Post Repair Procedures Post Repair Procedures ...