Chapter 12

12-3

Theory of Operation

How the Analyzer Works

How the Analyzer Works

Network analyzers measure the reflection and transmission characteristics of devices and

networks. A network analyzer test system consists of the following:

• source

• signal-separation devices

• receiver

• display

The analyzer applies a signal that is either transmitted through the device under test, or

reflected from its input, and then compares it with the incident signal generated by the

swept RF source. The signals are then applied to a receiver for measurement, signal

processing, and display.

The analyzer consists of a high resolution synthesized RF source, test set, and a dual

channel three-input receiver to measure and display magnitude, phase, and group delay of

transmitted and reflected power. Analyzers with Option 010 provide the additional

capability of transforming measured data from the frequency domain to the time domain.

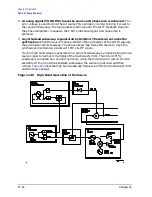

is a simplified block diagram of the network analyzer system. A detailed block

diagram of the analyzer is located at the end of

Chapter 4 , “Start Troubleshooting Here.”

Figure 12-1

Simplified Block Diagram of the Network Analyzer System

The Built-In Synthesized Source

The analyzer's built-in synthesized source produces a swept RF signal in the range of

30 kHz to 3.0 GHz. The Agilent 8753ET/ES Option 006 is able to generate signals up to

6 GHz. The source output power is leveled by an internal ALC (automatic leveling control)

circuit. To achieve frequency accuracy and phase measuring capability, the analyzer is

phase locked to a highly stable crystal oscillator.

For this purpose, a portion of the transmitted signal is routed to the R channel input of the

receiver, where it is sampled by the phase detection loop and fed back to the source.

Summary of Contents for 8753ES

Page 14: ...Contents xiv Contents ...

Page 15: ...1 1 1 Service Equipment and Analyzer Options ...

Page 26: ...1 12 Chapter1 Service Equipment and Analyzer Options Service and Support Options ...

Page 27: ...2 1 2 System Verification and Performance Tests ...

Page 203: ...3 1 3 Adjustments and Correction Constants ...

Page 262: ...3 60 Chapter3 Adjustments and Correction Constants Sequences for Mechanical Adjustments ...

Page 263: ...4 1 4 Start Troubleshooting Here ...

Page 297: ...5 1 5 Power Supply Troubleshooting ...

Page 317: ......

Page 318: ...6 1 6 Digital Control Troubleshooting ...

Page 337: ...6 20 Chapter6 Digital Control Troubleshooting GPIB Failures ...

Page 338: ...7 1 7 Source Troubleshooting ...

Page 369: ...7 32 Chapter7 Source Troubleshooting Source Group Troubleshooting Appendix ...

Page 370: ...8 1 8 Receiver Troubleshooting ...

Page 381: ...8 12 Chapter8 Receiver Troubleshooting Troubleshooting When One or More Inputs Look Good ...

Page 382: ...9 1 9 Accessories Troubleshooting ...

Page 389: ...9 8 Chapter9 Accessories Troubleshooting Inspect the Error Terms ...

Page 390: ...10 1 10 Service Key Menus and Error Messages ...

Page 439: ...10 50 Chapter10 Service Key Menus and Error Messages Error Messages ...

Page 440: ...11 1 11 Error Terms ...

Page 451: ...11 12 Chapter11 Error Terms Error Correction ...

Page 452: ...12 1 12 Theory of Operation ...

Page 482: ...13 1 13 Replaceable Parts ...

Page 487: ...13 6 Chapter13 Replaceable Parts Ordering Information Figure 13 1 Module Exchange Procedure ...

Page 500: ...Chapter 13 13 19 Replaceable Parts Replaceable Part Listings Figure 13 7 8753ET Cables Top ...

Page 502: ...Chapter 13 13 21 Replaceable Parts Replaceable Part Listings Figure 13 8 8753ES Cables Top ...

Page 512: ...Chapter 13 13 31 Replaceable Parts Replaceable Part Listings Figure 13 13 8753ES Cables Front ...

Page 544: ...14 1 14 Assembly Replacement and Post Repair Procedures ...

Page 550: ...Chapter 14 14 7 Assembly Replacement and Post Repair Procedures Covers Figure 14 2 Covers ...

Page 597: ...14 54 Chapter14 Assembly Replacement and Post Repair Procedures Post Repair Procedures ...