Summary of Contents for E4406A VSA Series

Page 4: ...4 ...

Page 10: ...10 Contents ...

Page 11: ...11 1 Troubleshooting ...

Page 66: ...66 Chapter1 Troubleshooting How to Return Your Instrument for Service ...

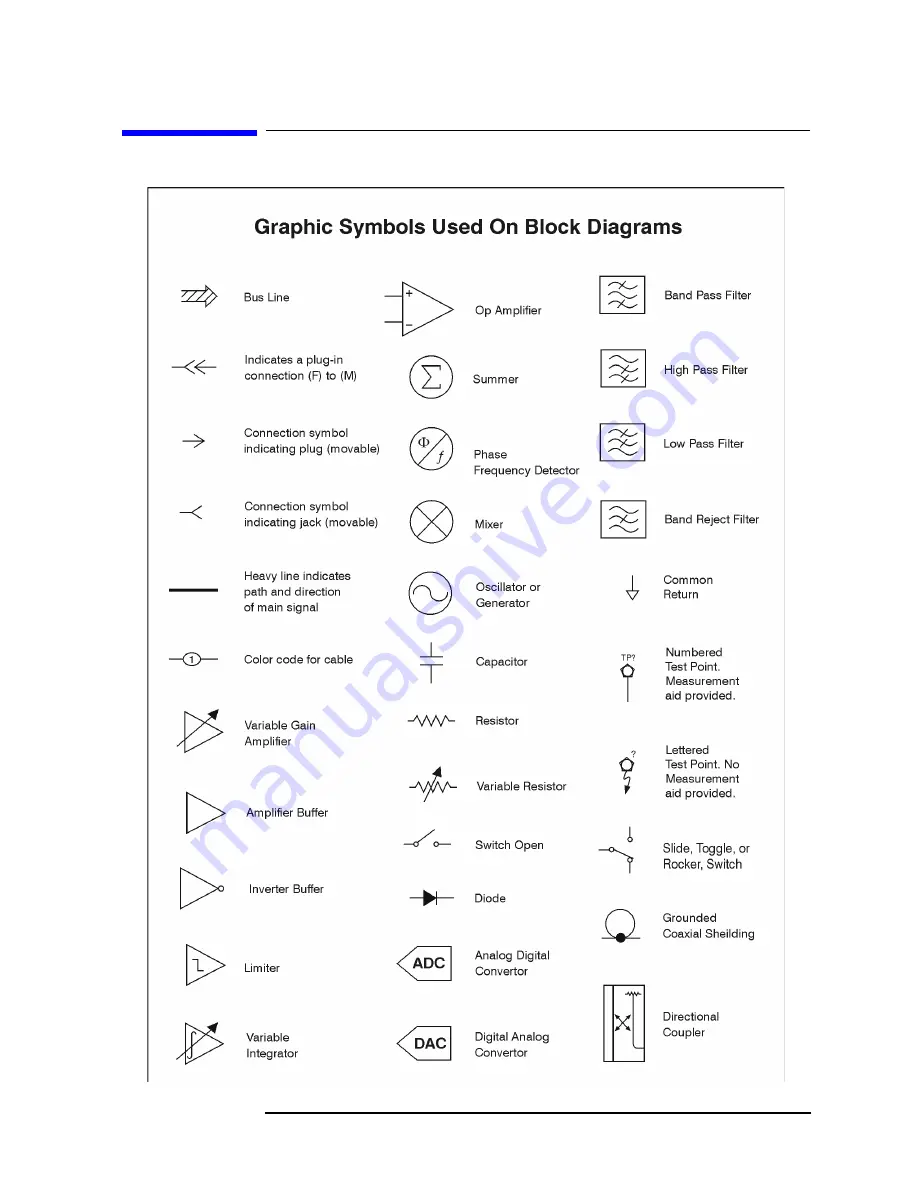

Page 67: ...67 2 Block Diagrams ...

Page 119: ...Chapter 2 119 Block Diagrams Block Diagrams Block Diagrams ...

Page 120: ...120 Chapter2 Block Diagrams Block Diagrams ...

Page 122: ...122 Chapter2 Block Diagrams Block Diagrams ...

Page 124: ...124 Chapter2 Block Diagrams Block Diagrams ...

Page 125: ...125 3 Parts List ...

Page 164: ...164 Chapter3 Parts List Hardware ...

Page 165: ...165 4 Assembly Replacement ...

Page 169: ......

Page 170: ...170 Chapter4 Assembly Replacement Removal and Replacement Procedures ...

Page 227: ...Chapter 4 227 Assembly Replacement Front Frame Subassemblies Figure 4 39 Keypad Parts ...

Page 231: ...231 5 Post Repair Procedures ...

Page 262: ...262 Chapter5 Post Repair Procedures Automated Adjustments ...