Chapter 6

89

Replacement Procedure

Required Tools

6. Re

placem

ent Pro

c

e

d

u

re

Required Tools

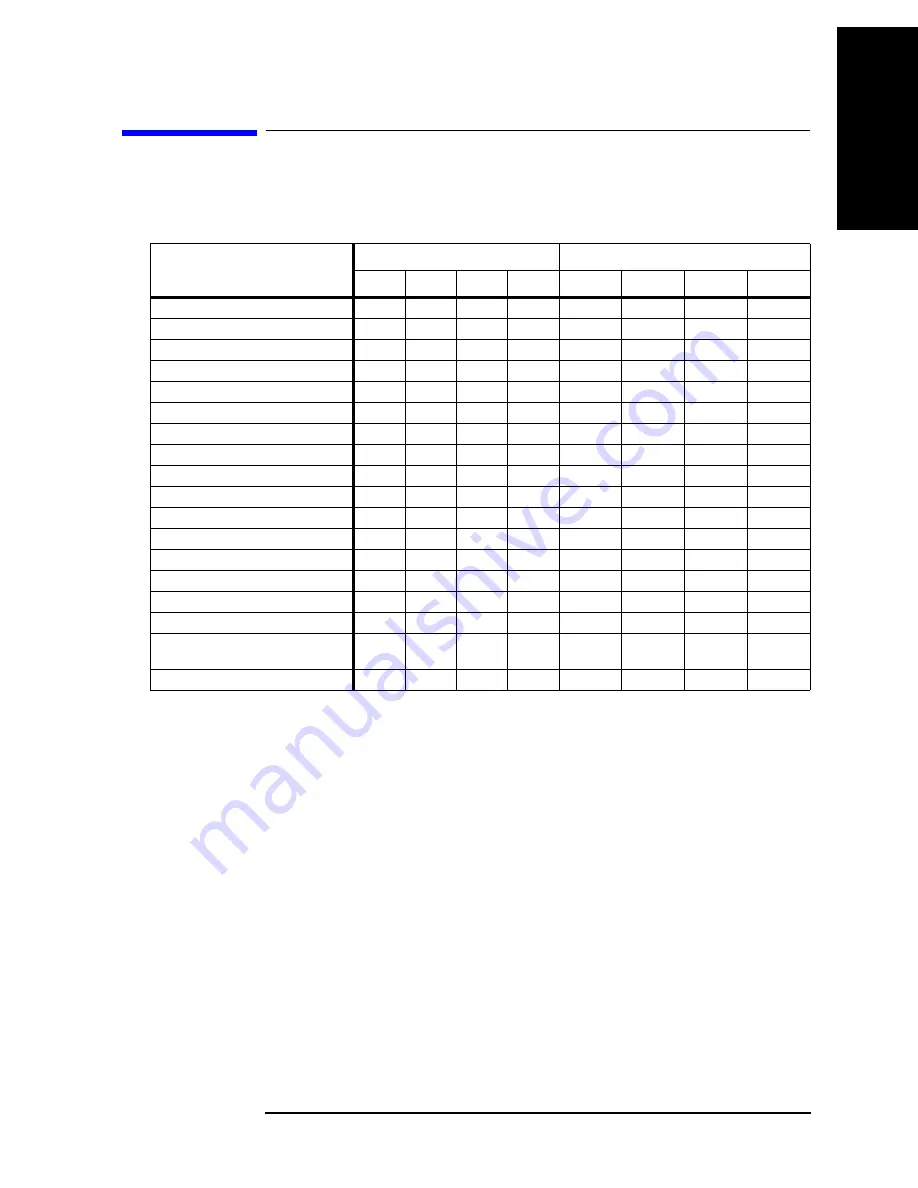

The following tools are required for repair of E4980A.

Table 6-1

Required Tools

Assembly

Torque screwdriver

Box torque wrench

T6

T8

T10

T20

5.5 mm

7 mm

3/8 in.

5/8 in.

3/4 Rack Module Top

A3 Analog Daughter Board

A2 Analog Board

Front Panel Assembly

Option Interface

PPMC PCA

A1 Mother Board

Power Supply Assembly

Base Plate

Rear Panel Assembly

FAN Assembly

GPIB Cable

Power Inlet Assembly

PCA E4980 USB

Binding Post Sgl

Inverter

Front Panel, Key Pad, and Key Flex

Circuit

Display Interface

Summary of Contents for E4980A

Page 12: ...12 Contents ...

Page 60: ...60 Chapter4 Troubleshooting Performance test failure troubleshooting ...

Page 86: ...86 Chapter5 Replaceable Parts Replaceable Parts List ...

Page 126: ...126 Chapter6 Replacement Procedure Display Interface Replacement ...

Page 136: ...136 AppendixB Firmware Update Update the E4980A firmware using USB cable ...

Page 140: ...140 AppendixC Power Requirement Power Requirements Figure C 3 Power Cable Supplied ...

Page 152: ...152 AppendixD Error Messages Error number 45 ...