380

Chapter 11

Limit Test

Limit Test

Turning the limit test ON/OFF

You can set the limit test ON/OFF for each trace individually.

Setting the limit test ON/OFF

The following steps explain how to set the limit test ON/OFF.

Step 1.

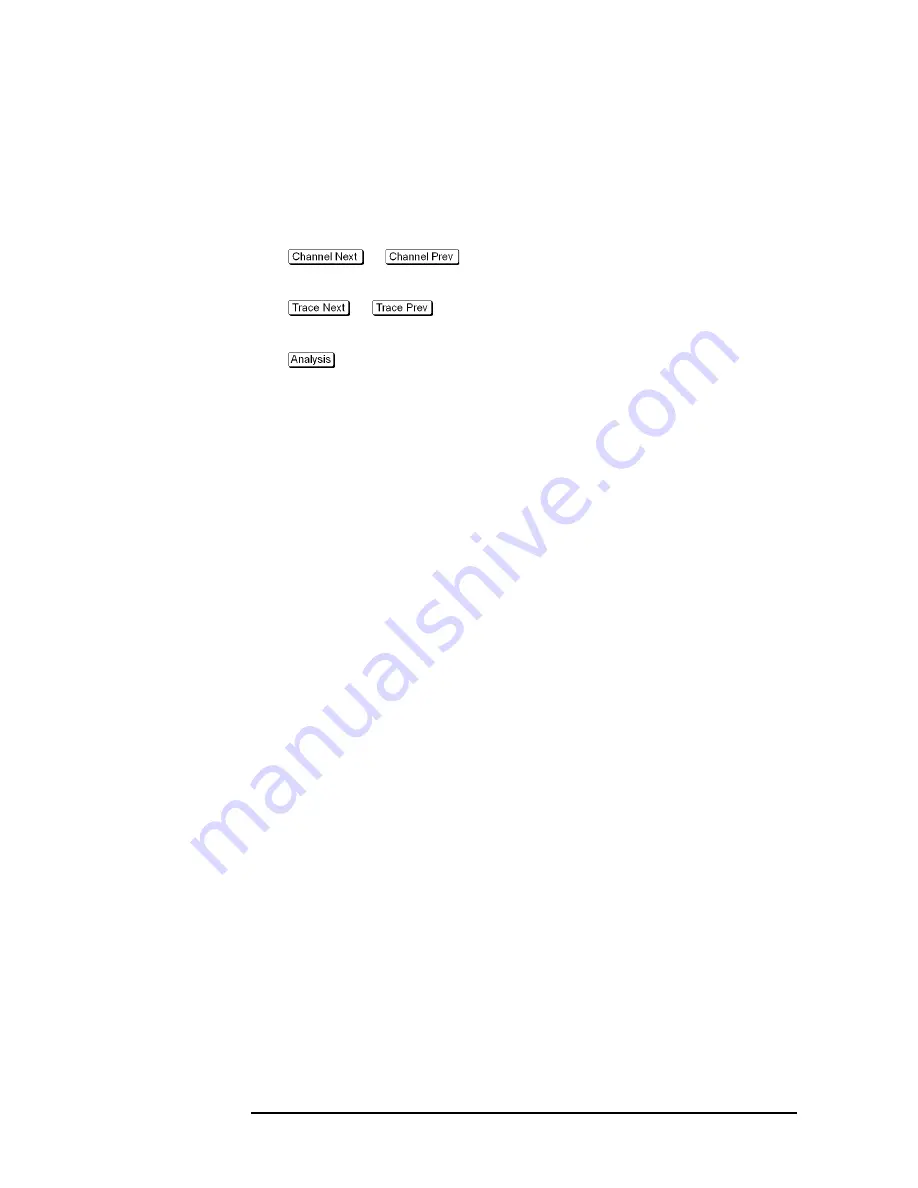

Press

or

to activate the channel on which the limit test function

will be used.

Step 2.

Press

or

to activate the trace on which the limit test function will be

used.

Step 3.

Press

to display the Analysis menu.

Step 4.

Press

Limit Test

to display the Limit Test menu.

Softkey

Function

Limit Test

Sets the limit test ON/OFF.

Limit Line

Sets the limit line display ON/OFF.

Edit Limit Line

Opens the limit table for editing the limit line.

*1.To use the limit test function, you must first define the limit line. For more on how to

define the limit line, see “Defining the limit line” on page 376.

*1

Step 5.

Press

Limit Test

to turn the limit test ON. To display the limit line on the screen, press

Limit Line

.

Summary of Contents for E5070B

Page 6: ......

Page 30: ...24 Contents ...

Page 34: ...28 Chapter1 Precautions Before contacting us ...

Page 286: ...280 Chapter6 Data Analysis Using the Equation Editor ...

Page 430: ...424 Chapter12 Optimizing Measurements Performing a Segment by Segment Sweep segment sweep ...

Page 538: ...532 Chapter15 Measurement Examples Executing Power Calibration ...

Page 634: ...628 AppendixB Troubleshooting Warning Message ...

Page 732: ...726 AppendixD Softkey Functions Trigger Menu ...

Page 740: ...734 AppendixE General Principles of Operation Data Processing ...

Page 760: ...754 AppendixF Replacing the 8753ES with the E5070B E5071B Comparing Functions ...