Page 4 of 10

E8364B-07A

c.

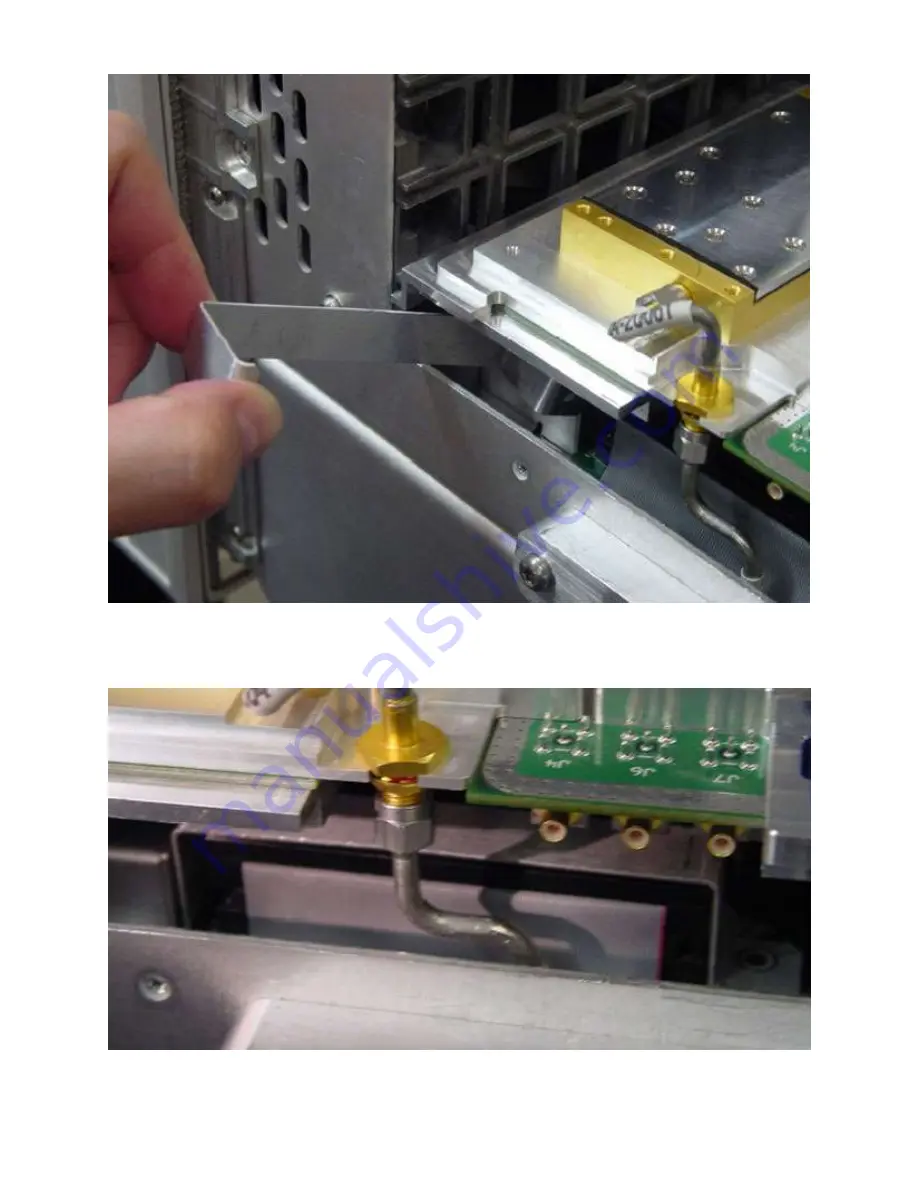

Position the clamp over the Ribbon Connector. Use needle nose pliers if necessary to slide the

clamp into place. Ensure that the edge of the clamp is parallel to the connector and not skewed.

NOTE: Ensure that the Clamp Lip is secured BELOW the edge of the System Motherboard