Installation Note E8364-90012

7

Overview of the Installation Procedure

Step 1. Remove the Outer Cover

Step 2. Remove the Front Panel Assembly

Step 3. Raise the Receiver Deck

Step 4. Remove the Existing Cables

Step 5. Install the Option 014 Cables

Step 6. Lower and Fasten the Receiver Deck

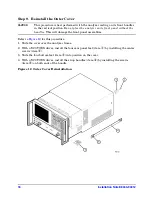

Step 7. Replace the Lower Front Panel Overlay

Step 8. Reinstall the Front Panel Assembly and Install the Front Panel Jumpers

Step 9. Reinstall the Outer Cover

Step 11. Perform Post-Upgrade Adjustments and Calibration

Tools and Equipment Required for the Installation

CAUTION

Use a 5/16-in torque wrench set to 10 in-lbs on all cable connections except the

front-panel connectors to which the front-panel jumpers attach. Use a 5/16-in

torque wrench set to 21 in-lbs for these connections.

Equipment Required for Post-Upgrade Adjustments

Description

Qty

Part Number

T-10 TORX driver (set to 9 in-lbs)

1

N/A

T-20 TORX driver (set to 21 in-lbs)

1

N/A

5/16 in torque wrench (set to 10 in-lbs)

1

N/A

5/16 in torque wrench (set to 21 in-lbs)

1

N/A

ESD grounding wrist strap

1

9300-1367

5 ft grounding cord for wrist strap

1

9300-0980

2 x 4 ft conductive table mat and 15 ft grounding wire

1

9300-0797

ESD heel strap (for use with conductive floors)

1

9300-1308

Equipment Type

Model or

Part Number

Alternate Model or

Part Number

Power meter

E4418B/E4419B

E4418A/E4419A

Power sensor, 2.4 mm

8487A

None

Adapter, 2.4 mm (f) to 2.4 mm (f)

11900B

85056-60007

RF cable, 2.4 mm (f) to 2.4 mm (f)

85133C

85133E