Installation Note E8364-90011

13

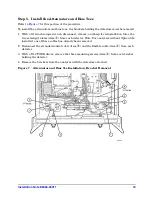

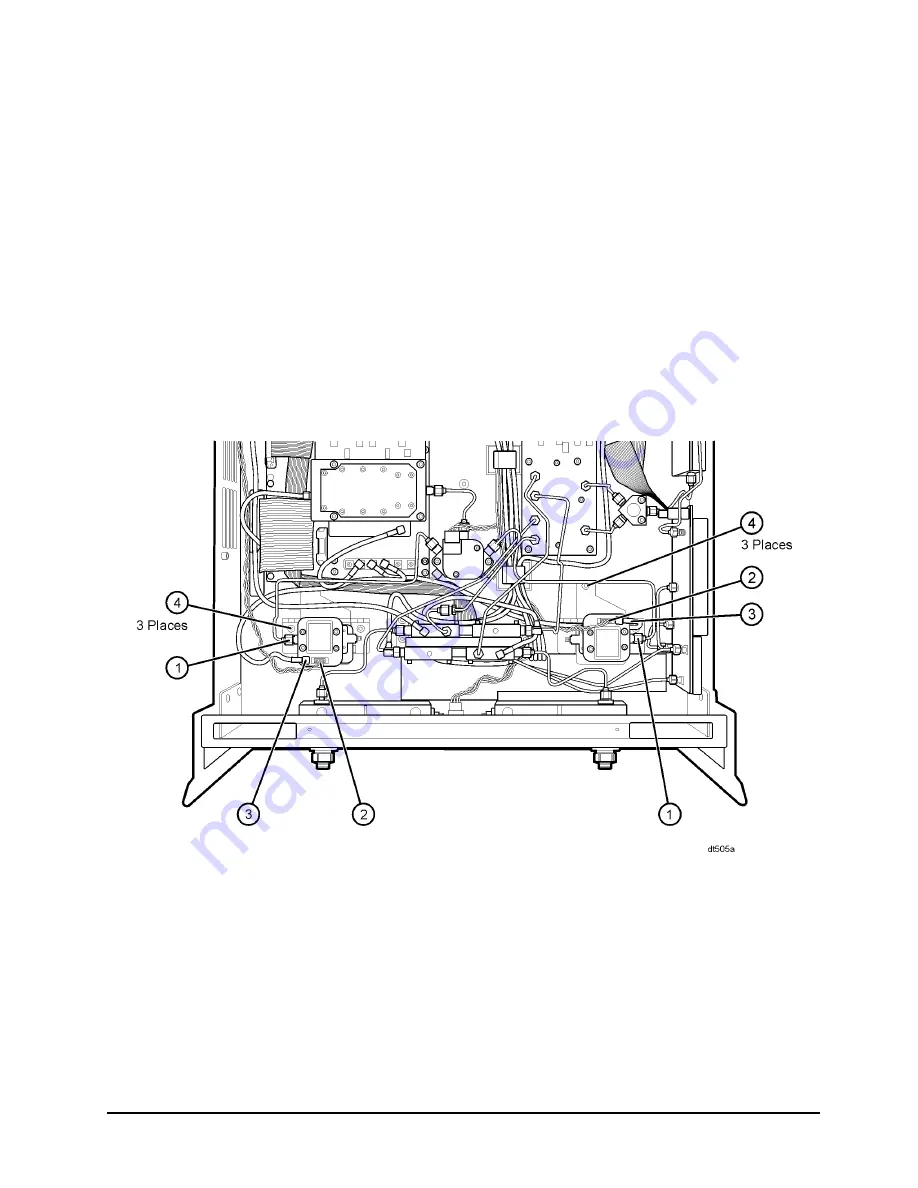

Step 5. Install the Attenuators and Bias Tees

Refer to

for this portion of the procedure.

To install the attenuators and bias tees, the brackets holding the detectors must be removed.

1. With a 5/16-inch torque wrench, disconnect, remove, and keep for reinstallation later, the

two semirigid cables (item

①

) from each detector. Note: For analyzers without Option 014

installed, one of these cables has already been removed.

2. Disconnect the stranded control cable (item

②

) and the flexible cable (item

③

) from each

detector.

3. With a T-10 TORX driver, remove the three mounting screws (item

④

) from each bracket

holding the detector.

4. Remove the brackets from the analyzer with the detectors attached.

Figure 7

Attenuator and Bias Tee Installation, Bracket Removal