Operating in Electron Ionization (EI) Mode

3

5977 Series MSD Operation Manual

53

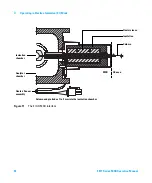

The EI GC/MSD Interface

The GC/MSD interface (

54) is a heated conduit into the MSD

for the capillary column. It is bolted onto the right side of the analyzer

chamber, with an O-ring seal. It has a protective cover which should be left in

place.

One end of the GC/MSD interface passes through the side of the gas

chromatograph and extends into the GC oven. This end is threaded to allow

connection of the column with a nut and ferrule. The other end of the

interface fits into the ion source. The last 1 to 2 mm of the capillary column

extend past the end of the guide tube and into the ionization chamber.

The GC/MSD interface is heated by an electric cartridge heater. Normally, the

heater is powered and controlled by Thermal Aux #2 heated zone of the GC.

The interface temperature can be set from MassHunter Data Acquisition or

from the gas chromatograph. A sensor (thermocouple) in the interface

monitors the temperature.

The GC/MSD interface should be operated in the 250

to 350

C range. Subject

to that restriction, the interface temperature should be slightly higher than the

maximum GC oven temperature, but

never

higher than the maximum column

temperature.

The EI GC/MSD interface can only be used with an EI ion source. There are

two types of tip seals that may be used with EI ion sources. The standard/inert

EI ion sources do not need a tip seal. The extractor ion source on an EI only

system uses a tip seal (G3870-20542). The extractor ion source and the CI ion

source on an EI/CI system uses the CI tip seal (G1999-60412).

See also

“To Install a Capillary Column in the GC/MS Interface”

WA R N I N G

The GC/MSD interface operates at high temperatures. If you touch it when it is hot,

it will burn you.

Summary of Contents for G7035A

Page 1: ...Agilent Technologies Agilent 5977 Series MSD Operation Manual ...

Page 30: ...30 5977 Series MSD Operation Manual 1 Introduction ...

Page 88: ...88 5977 Series MSD Operation Manual 3 Operating in Electron Ionization EI Mode ...

Page 170: ...170 5977 Series MSD Operation Manual 6 CI Maintenance ...

Page 171: ......