Installation Note

E4440-90632

13

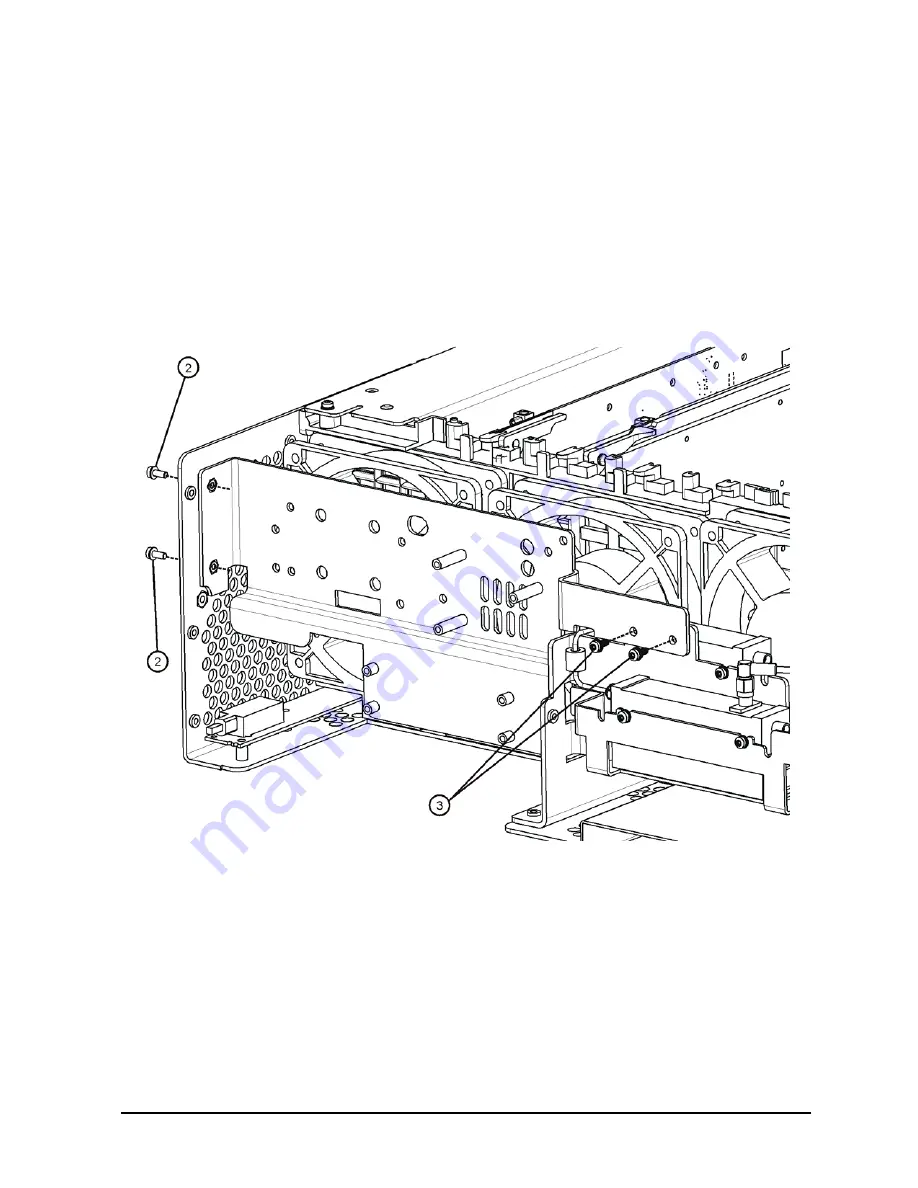

Installation Procedure

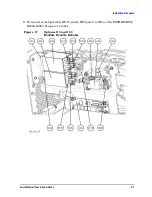

Installing the Preamplifier without Option 123

1. Locate the Main Bracket (

) from the kit and install it as shown

(1)

.

a. Insert two screws (0515-0458) labeled as

(2)

. Use T-15 driver to torque to 9 in-lbs.

b. Insert two screws (0515-0372) labeled as

(3)

. Use T-15 driver to torque to 9 in-lbs

Figure 6

Installing Bracket