Chapter 2: Unpacking and installing the workstation

BenchCel Microplate Handling Workstation R-Series User Guide

30

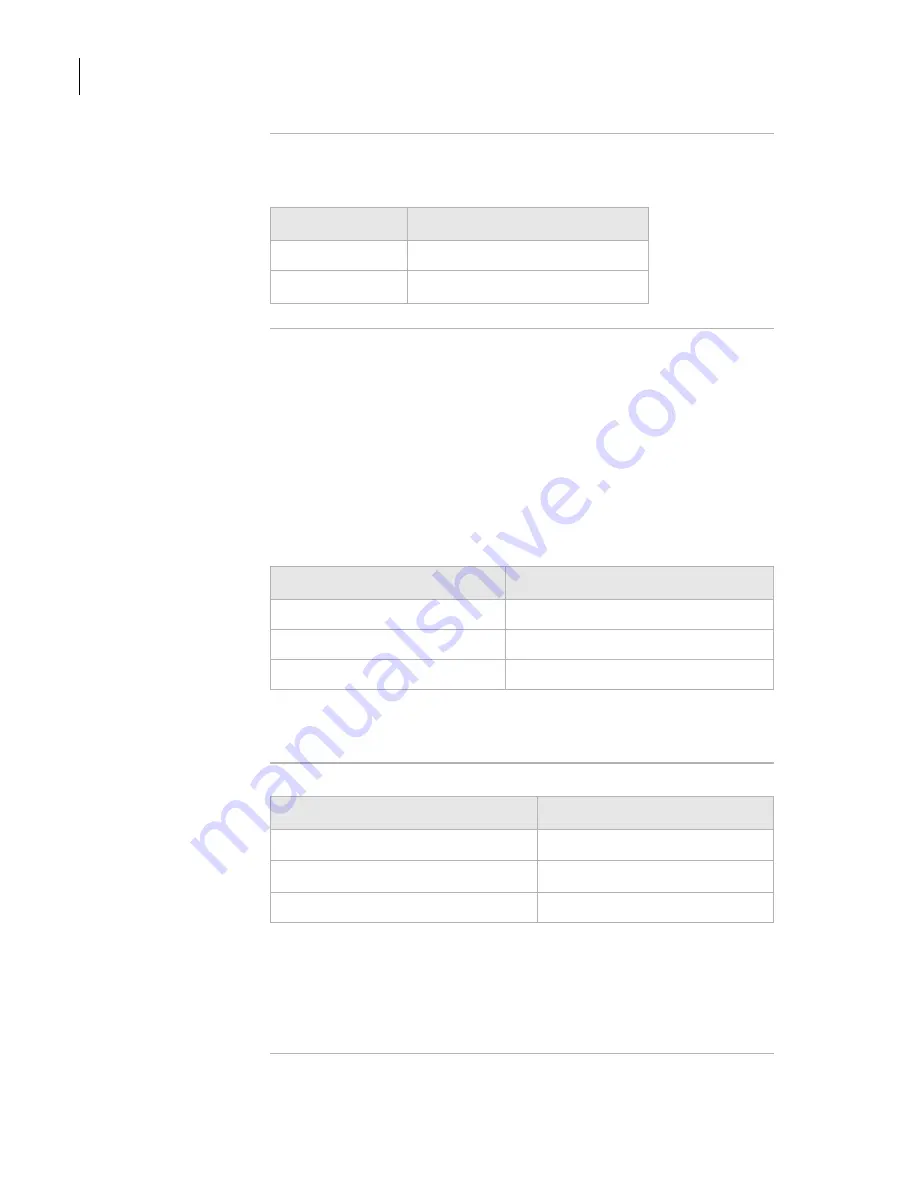

Electrical

The BenchCel device has the following power requirements. For power

requirements of other devices in the workstation, see the device user

documentation.

Compressed air

The BenchCel device requires the use of clean, dry, compressed air to

move pneumatic components inside the device. The compressed air

can be from the following sources:

❑

Centralized source (house)

❑

Compressed-air cylinders

❑

Portable pumps

!! DAMAGE HAZARD !!

Using oil compressors can cause oil to

leak into the BenchCel device and void your warranty.

To maintain the desired air supply in the device, the BenchCel device

requires a source of air as follows:

!! DAMAGE HAZARD !!

Air pressure greater than 0.69

MPa

(100

psi) can damage the BenchCel Workstation.

Environment

The lab must meet the following environmental requirements.

Velocity11 recommends that you do the following:

❑

Place the BenchCel Workstation away from heat and air

conditioning ducts.

❑

Place the BenchCel Workstation away from direct sunlight.

Utility

Requirement

Electrical

100–240~, 50/60 Hz, 5 A

Fuse

5 A, 250 V, 5

×

20 mm, fast acting

Requirement

Value

Quality

Clean, dry, compressed

Flow rate

340 Lpm (1.2 cfm)

Pressure

0.65–0.69 MPa (95–100 psi)

Requirement

Value

Ambient temperature

5–40

°C

Humidity condition

10–90%

RH, non-condensing

Elevation

1–2000 m

Summary of Contents for R Series

Page 4: ...Letter to our Customers 2 Agilent Technologies Inc Automation Solutions Division ...

Page 10: ......

Page 23: ......

Page 24: ......

Page 26: ......

Page 34: ...Preface BenchCel Microplate Handling Workstation User Guide viii ...

Page 60: ...Chapter 1 Introduction BenchCel Microplate Handling Workstation R Series User Guide 26 ...

Page 124: ...Chapter 4 Performing a run BenchCel Microplate Handling Workstation R Series User Guide 90 ...

Page 210: ...Appendix B Quick reference BenchCel User Guide 176 ...

Page 218: ...Index BenchCel Microplate Handling Workstation R Series User Guide 184 ...

Page 219: ......

Page 220: ...Agilent Technologies User Guide G5400 90001 ...