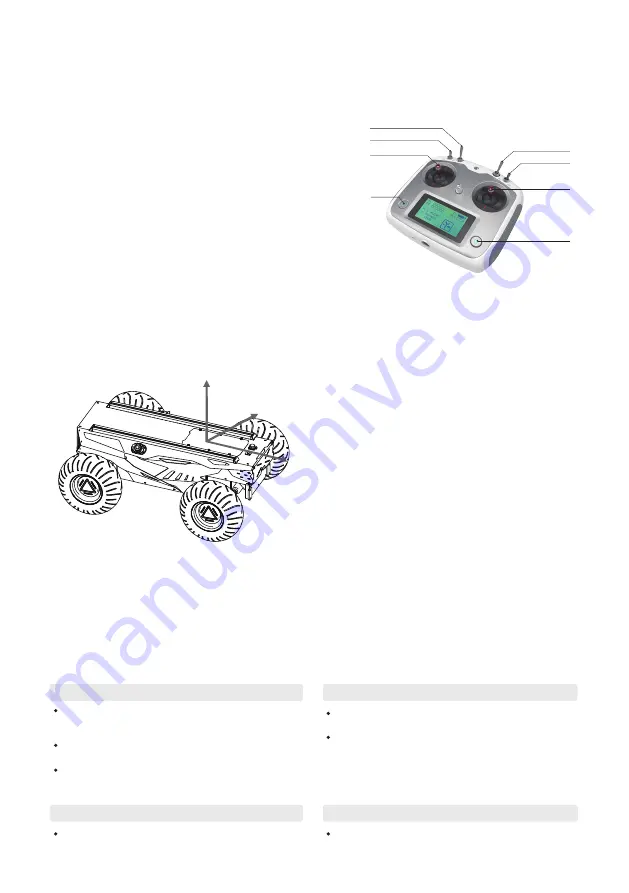

FS RC transmitter is provided (optional) for HUNTER 2.0. In this product, we use the left-hand-throttle design. Refer to Figure 2.8 for its

definition and function.

This section introduces the basic operation and development of the HUNTER 2.0 platform using the CAN bus

interface.

The function of the button is defined as: SWC and SWD are

temporarily disabled. Among which SWA is the parking switch

lever, turn to the top to release the parking mode, turn to

bottom is the parking mode. (The remote control can be

performed normally after the parking mode is released.) SWB

for control mode selection, top position for command control

and the middle position for remote control mode; S1 is the

throttle button, which controls the forward and backward of

HUNTER 2.0; S2 controls the steering of the front wheels, and

POWER is the power button, press and hold it to turn on.

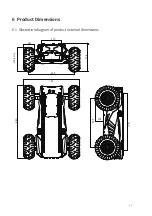

As shown in Figure 2.9, the chassis body of HUNTER 2.0 is in parallel with X

axis of the established reference coordinate system. In the remote control

mode, push the remote control stick S1 forward to move in the positive X

direction, push S1 backward to move in the negative X direction. When S1

is pushed to the maximum value, the movement speed in the positive X

direction is the maximum, When pushed S1 to the minimum, the

movement speed in the negative direction of the X direction is the

maximum; the remote control stick S2 controls the steering of the front

wheels of the car body, push S2 to the left, and the chassis turns to the left,

pushing it to the maximum, and the steering angle is the largest, S2 Push

to the right, the car will turn to the right, and push it to the maximum, at

this time the right steering angle is the largest. In the control command

mode, the positive value of the linear velocity means movement in the

positive direction of the X axis, and the negative value of the linear velocity

means movement in the negative direction of the X axis; the steering angle

is the steering angle of the inner wheel.

A reference coordinate system can be defined and fixed on the chassis body as shown in Figure 2.9 in accordance with ISO 8855.

2.4 Instructions on control demands and movements

2.3 Remote control instructions

Figure 2.8 Schematic Diagram of Buttons on FS RC transmitter

SWC

SWD

S2

SWB

SWA

S1

POWER

POWER

3 Getting Started

3.1 Use and operation

The basic operating procedure of startup is shown as follows:

Check

Shutdown

Emergency stop

Startup

Check the condition of HUNTER 2.0. Check whether there are

significant anomalies; if so, please contact the after-sale service

personal for support;

Check the state of emergency-stop switches. Make sure both

emergency stop buttons are released;

For first-time use, check whether Q3 (drive power supply switch)

on the rear panel has been pressed down; if so, please release it,

and then the drive will be powered off.

Press the button Q3 to cut off the power supply.

Press down emergency push button on the top of HUNTER 2.0

chassis body.

Press Q3 button, and normally, the voltmeter will display correct

battery voltage and front and rear lights will be both switched on;

Check the battery voltage, the normally voltage range is 24~26.8V,

if there is continuous “beep-beep-beep...” sound from beeper,it

means the battery voltage is low, please charge the battery.

5

Figure 2.9 Schematic Diagram of Reference Coordinate System for Chassis Body

Z

Y

X