workpiece surfaces will be machined

unevenly. Replace when worn as follows:

1.

Using the supplied hook spanner

wrench, engage one of the holes in

the tool holder to immobilize it.

2.

Using an appropriate sized wrench

loosen the nut securing the impeller

and remove.

3.

Replacement is the reverse of removal.

● THE CARBON BRUSHES

1800W Electric Beveler Mode only

The carbon brushes are a normal wearing

part and must be replaced when they

reach their wear limit.

Caution: Always replace the brushes as a

pair

For 1800W models:

To replace:

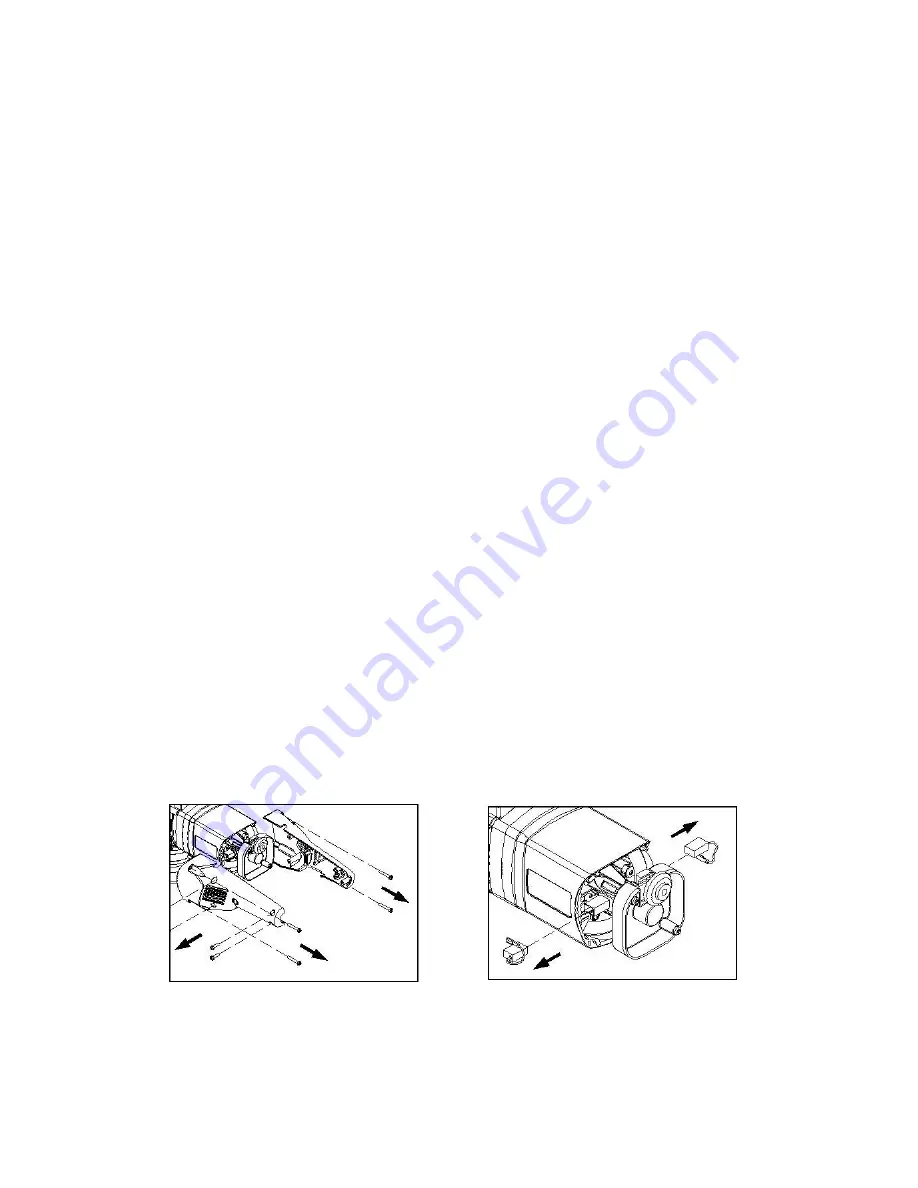

First unplug the machine. Carefully remove

the 4 screws to separate the rear handle

halves and then remove the 4 screws which

connect the handle to the motor housing.

Lift away the left-hand handle half first.

There will still be wires connected to the

rear handle, so take care that these are not

stressed. Simply hold the rear handle off to

one side.

Using pliers, rotate the brush spring out of

the way and slide old carbon brush out of

the brush holder . Unplug the spade

connector to remove the brush lead. The

old carbon brush may now be lifted away.

Replacing is the reverse of removal. When

Replacing the rear handle to the motor

housing, take great care that all wires are in

place and not in a position to be pinched

14

Summary of Contents for 1100W Electric Beveler model B16

Page 15: ...WIRING 1800W Mode 17 ...

Page 17: ......

Page 22: ......

Page 23: ......

Page 24: ......