23

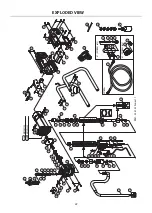

PARTS LIST

NO. Parts Name

Q'TY

1

SOCKET CAP SCREW M5 x 50

3

2

SOCKET CAP SCREW M5 x 25

1

3

SOCKET SET SCREW M5 x 6

2

4

GEAR HOUSING (SILVER)

1

5

PANHEAD MACHINE SCREW M4 x 8

4

6

FENCE30 x 45 x 1.5

1

7

PANHEAD MACHINE SCREW M3 x 16

2

8

LIMIT SWITCH

1

9

TRUSS HEAD MACHINE SCREW M5 x 15

1

10 PRESSURE ADJUSTOR KNOB

1

11 PRESSURE ADJUSTOR SCREW

1

12 SLEEVE

1

13 SOCKET SET SCREW M4 x 4

2

14 ADJUSTOR SLEEVE

1

15 INTERNAL CIRCLIP IS-17

1

16 SPRING TH14-040

1

17 PRESSURE PISTON

1

18 BALL BEARING 6200-ZZ

1

19 EXTERNAL CIRCLIP IR-28

2

20 PISTON/CONNECTING ROD ASSY

1

21 NEEDLE BEARING TLA2212

1

22 SPINDLE 4.5mm

1

23 PARALLEL KEY 5 x 5 x 10

1

24 INPUT GEAR M1.0 x 86T

1

25 BALL BEARING 6000-ZZ

1

26A MOTOR UNIT 110V

1

26B MOTOR UNIT 220V

1

27 CARBON BRUSH 7 x 11 x 16

2

28 BRUSH CAP

2

29 FUSE PLATE

1

30 FUSE 250V-10A

1

30 FUSE 250V-6A

1

31 PANHEAD TAPPING SCREW-B M4 x 12

4

32 SWITCH PANEL

1

33 POWER SWITCH

1

34 MOTOR SIDE COVER-RIGHT

1

35 CABLE GLAND SB8R-3

1

36 ELECTRONICS UNIT 110V

1

36 ELECTRONICS UNIT 220V

1

37 PANHEAD TAPPING SCREW M4 x 14

4

38 MOTOR SIDE COVER-LEFT

1

39 PANHEAD TAPPING SCREW M4 x 35

6

40 PANHEAD TAPPING SCREW M4 x 30

2

41 PANHEAD TAPPING SCREW M4 x 20

2

42 SOCKET CAP SCREW M5 x 25

4

43 BUSHING Ø26 x Ø32 x 30

1

44 EXTERNAL CIRCLIP IR-32

1

45 DRIVE PISTON

1

46 PUMP WRIST PIN Ø10 x 23.5

1

47 PACKING NUT

1

NO. Parts Name

Q'TY

48 SEAL SEAT

1

49 O-RING S-31.5

1

50 O-RING Ø31.2 x Ø35.1 x 1.8

1

51 CHECK BALL & PISTON PACKING

1

52 DISC SPRING

3

53 DISPLACEMENT PISTON

1

54 BALL SEAT Ø4 x Ø13.8 x 4

1

55 O-RING

1

56 BALL SEAT FASTENER M16

1

57 PACKING SPACER

1

58 PUMP HOUSING

1

59 PRESSURE ACTUATOR

1

60 OUTPUT NIPPLE PT 1/4" x 1/4"-19PF

1

61 SOCKET SET SCREW-SUS PT1/4"-SUS

1

62 PRIMING VALVE

1

63 DRAIN TUBE PT1/8" x 0.92M

1

64 FLAT WASHER 1/4" x Ø10 x 1

4

65 SOCKET CAP SCREW M6x110

4

66 SPACER Ø25.5 x Ø37 x 7

1

67 INNER SPACERØ22 x Ø32 x 9

1

68 BALL GUIDE

1

69 BALL SEAT Ø9 x Ø20 x 5

1

70 GLAND NUT

1

71 HOSE CLIP

1

72 O-RING Ø2.4 x Ø19.8 x Ø24.6

2

73 SUCTION HOSE

1

74 INLET STRAINER

1

75 SOCKET CAP SCREW M8 x 35

4

76 FRAME

1

77 FRAME-LEFT

1

78 POWER SUPPLY CABLE

1

79 HIGH PRESSURE HOSE 7.5M 3300 PSI 1/4"-19UNF

1

79 HIGH PRESSURE HOSE 16.5M 3300 PSI 1/4"-19UNF

1

80 TUBE HOLDER Ø11 x Ø22

5

81 N/A

-

82 PRESSURE ADJUSTOR GRIP

1

83 PACKING NUT TOMMY BAR

1

84 LUBRICATING OIL TANK100 cc

1

85 SPACERØ10 x Ø15 x 2

1

A1 FILTER ASSY.

1

A1-1 FILTER NUT

1

A1-2 ARBOR SPACER DISC Ø11 x Ø20 x 4

1

A1-3 FILTER

1

A1-4 FILTER HOUSING

1

A1-5 ARBOR SPACER DISC

1

A1-6 SOCKET CAP SCREW M5 x 35

4

A1-7 SPRING Ø0.5x Ø8.5x Ø9.5x9Tx28L

1

A2. PRESSURE GUAGE ASSY.

1

A2-1 AIR PRESSURE GUAGE

1

A2-2 RUN TEE

1

Summary of Contents for 700W Mechanical

Page 1: ...Original Instructions ...

Page 24: ......