11

Placing the hand on the machine may result in an electric shock in the event of a voltage leak or if the

machine cuts its own power supply cable.

c.

Always ensure that the work piece is a minimum of 12mm (7/16 in.) thick. If it is not, then use a

piece of steel plate at least 12mm thick and larger than the magnet, below the work piece, to

supplement the magnetic adhesion.

The magnet’s adhesion depends on the thickness of the work

piece.

d. Do not operate the machine on a workpiece while it is being welded.

This may lead to damage to the

machine and/or personal injury.

e.

Never position machine on a work piece between the electrode and the ground of any arc type

welder.

The welder’s current will ground through the earth wire in the machine’s power supply cable,

causing it damage.

f.

Do not exceed 90 degrees from horizontal.

It is hazardous to use the drill upside-down.

g. Always ensure that the magnet is clean and free of rust and scale.

Metal chips and other debris will

hamper magnetic adhesion.

h. Always use the tool alone on the receptacle.

Other units used on the same receptacle could cause

uneven voltage that could lead to the magnet releasing.

i.

Ensure that the magnet has properly adhered to the work piece before beginning drilling.

Proper

magnet adhesion is essential for safe drilling.

j.

When drilling non-ferrous (non-magnetic) work materials, only use a manufacturer-approved

fixture such as a vacuum base adapter.

Use of accessories which are not manufacturer-approved

could result in a hazardous situation.

k.

Do not operate with dull or damaged cutting tools.

This may overload the motor.

l.

Avoid operating annular cutters without cutting fluid.

Always check fluid level before operating.

Annular cutters require cutting fluid for proper operation and long life.

m. Protect the motor. Never allow cutting fluid, water, or other contaminants to enter the motor.

This

could lead to electric shock or motor damage.

n. When drilling stacked work materials, always stop to clear the slug after the first layer is drilled.

The loose slug will interfere with proper drilling.

o.

CAUTION: Never attempt to use machine with incorrect current or abnormally low voltage.

Incorrect voltage could lead to motor damage.

p. This machine is not intended for production-line type use.

MAGNET BASE DUTY CYCLE

Do not leave the magnet base activated continuously for more than 60 minutes. If the magnet base is

overheated, allow it to cool for 30 minutes before continuing.

CAUTION:Turn the magnet base off when not in use. Leaving the magnet base on continuously will

damage it.

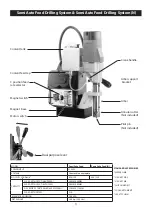

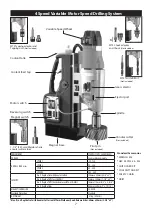

ASSEMBLY

Coolant tank assembly required.

First attach clear tube to the bottom of the coolant tank. To do this, first

loosen the nut and slide nut onto the tube. Then slide tube onto the nipple. Then tighten the nut. Slide tank

hanger over the screw on the upper right hand side of slide and tighten. Finally insert the other end of the

tube into the quick-release connector in the gearbox. Just directly push in to install.

(To remove, first firmly

Summary of Contents for MD120/4

Page 44: ......