18

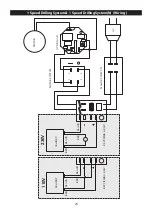

NOTE: the left and right side gear selectors have a different engagement design:

For The LEFT HAND SLIDER must ALWAYS ensure that the machine is FULLY STOPPED before attempting

to change gears! NEVER change the Left hand slider gears on a running machine!

For the RIGHT HAND SLIDER the gears select by engagement dogs, similar to a motorcycle transmission

design. These MUST BE SELECTED BY TURNING THE ARBOR to allow the dogs to engage.

CAUTION: Ensure that that gears engage fully.

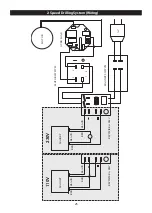

VARIABLE MOTOR SPEED MODELS ONLY

The electronic variable motor speed control allows the motor speed to be lowered for further flexibility for

adjusting the cutting speed to suit the size of cutter and type of

material. Simply turn the thumb wheel to raise or lower the motor

speed electronically.

NOTE: whenever possible, it is always preferable to lower the speed

by changing the gear rather than lowering the motor speed. A

slower motor speed will have less cooling and somewhat less

torque so always try to keep the motor going as fast as possible.

Only lower the motor speed if you have no other option.

(For example: If you need the RPM at about 100/min, it is much

better to use 1st gear at full motor speed than to use 3rd gear at

minimum motor speed.)

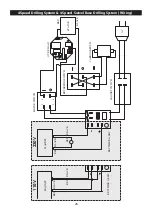

Avoid overheating the motor:

When using the machine at or near maximum capacity with a slow motor speed the motor will be at

maximum stress and very hot. After each cut is finished,

ALWAYS

cool the motor by running at no load at the

maximum motor speed for a few minutes.

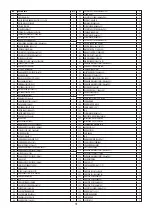

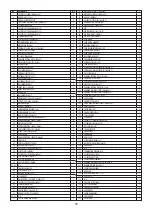

CUTTING SPEEDS

The type of material to be drilled, its hardness and thickness will all greatly affect the recommended cutting

speed. See the chart below for general guidelines for cutting speeds. Use the formula to determine the

recommended RPM for the diameter of annular cutter being used:

RECOMMENDED SURFACE SPEEDS

Note: work materials which have been flame cut will be heat treated in the affected area. These areas

will require much slower cutting speeds.

Variable Speed Wheel

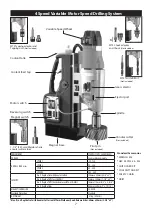

Summary of Contents for MD120/4

Page 44: ......