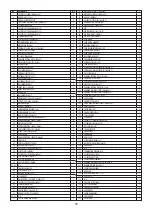

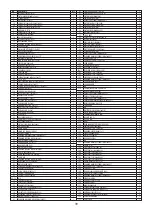

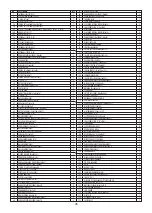

29

66

SOCKET SET SCREW (M5x20xP0.8)

5

67

HEX NUT (M5xP0.8)

5

68

GIB STRIP-LEFT (258MM)

1

69

GIB STRIP-RIGHT (258MM)

1

70

GIB TENSIONER (258x11x1.2T)

1

71

ELECTROMAGNET (164x80x48)

1

72

SIDE PANEL (110x90x1.5T)

1

73

PANHEAD MACHINE SCREW (M4x16xP0.7)

1

74

EXTERNAL STAR WASHER (M5)

1

75

HEX NUT (M4xP0.7)

8

76

SPRING WASHER (M6)

3

77

CABLE CLAMP

2

78

PANHEAD MACHINE SCREW (M4x30xP0.7)

2

79

RECTIFIER (110&220V)

1

79-1

RECTIFIER & EMC (110V&220V)

1

80

CABLE GLAND (5/16")

1

81

CABLE CLIP

2

82

CABLE PROTECTOR (5/16"x7CM)

1

83

CORD ARMOR

1

84

POWER SUPPLY CABLE

1

85

N/A

-

86

WIRE LEAD (1015-16#18CM)

2

87

FLAT WASHER (Ø6xØ13x1)

2

88

BUTTERFLY SCREW (M6x10xP1.0)

2

89

CHIP GUARD

1

90

N/A

-

91

COMBINATION WRENCH (M8)

1

92

HEX KEY (M2.5)

1

93

HEX KEY (M4)

1

94

WIRE LEAD (1015-16#18CM)

4

95

SOCKET CAP SCREW (M4x16xP0.7)

4

96

SPRING WASHER (M4)

4

97

FLAT WASHER (Ø4xØ10x1)

5

98

SWITCH GUARD BAR (90MM)

2

99

OVER LOAD PROTECTION (110V/220V)

1

100

RUBBER WASHER (Ø4xØ11x1)

1

101

FEMALE SPADE TERMINAL

4

102

SPADE TERMINAL BOOT

8

103

ZIP TIE (2.4x80MM)

1

104

PANHEAD MACHINE SCREW (M4x25xP0.7)

3

105

LOCK PIN (12.3MM-11.7MM)

2

106

PANHEAD MACHINE SCREW (M3x4xP0.5)

2

107

LOCK PIN SPRING

2

108

CHECK BALL (Ø8)

1

109

RING (Ø40xØ44x9)

1

110

COLLAR PIN (Ø8)

1

111

QUICK-RELEASE COLLAR

1

112

SPRING (Ø2.3xØ39xØ43.6x3Tx30L)

1

113

SPRING SEAT RING (Ø35.1xØ44.5x2)

1

114

EXTERNAL CIRCLIP (S-35)

1

115

CHUCK (1/2")

1

116

CHUCK ADAPTOR (M27 / 1/2")

1

117

N/A

-

118

PILOT PIN (HSSx77LxØ6.34)

1

118

PILOT PIN (HSSx103LxØ6.34)

1

118

PILOT PIN (TCTx90LxØ7.98)

1

118

PILOT PIN (TCTx90LxØ6.34)

1

118

PILOT PIN (TCTx106LxØ6.34)

1

118

PILOT PIN (TCTx108LxØ7.98)

1

119.

PARALLEL KEY (4x4x8)

1

120

EARTHING MARKING

1

121

FAN SHROUD

1

122

SAFETY BELT

1

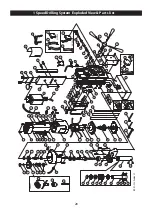

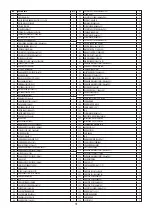

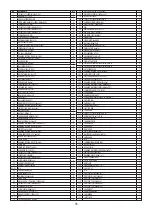

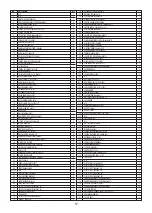

NO.

Parts Name

Q'TY

1

SOCKET SET SCREW (M8x7xP1.25)

2

2

ARBOR (M27-122.5L)

1

2-1

QUICK RELEASE ARBOR SHAFT (M27-122.5L)

1

3

ARBOR SUPPORT BRACKET

1

4

TRUSS HEAD MACHINE SCREW (M5x8xP0.8)

2

5

NEEDLE BEARING (HK 3516)

1

6

SPRING WASHER (M8)

3

7

SOCKET CAP SCREW (M8x55xP1.25)

2

8

SOCKET CAP SCREW (M8x30xP1.25)

1

9

WATER SEAL (Ø16x16)(WHITE)

1

10

SPRING (Ø1.5xØ13.3xØ16.3x16Tx140L)

1

11

SPINDLE (M27-112.5MM)

1

12

PARALLEL KEY (5x5x10)

1

13

OIL SEAL (Ø28xØ40x7)

2

14

PANHEAD TAPPING SCREW (M5x60)

6

15

GEAR HOUSING

1

16

PUSH LOCK FITTING (PT1/8"xØ6)

1

17

BALL BEARING (6003)

2

18

INTERNAL CIRCLIP (R-35)

1

19

EXTERNAL CIRCLIP (S-17)

1

20

LAY GEAR (M1.0x52T)

1

21

EXTERNAL CIRCLIP (S-15)

1

22

BALL BEARING (608)

4

23A

INPUT SHAFT (M1.0x8T)

1

24A

INPUT GEAR (M0.7x50T)

1

25

PARALLEL KEY (4x4x30)

1

26

GEAR PLATE

1

27

BALL BEARING (609)

1

28

ARMATURE (110V-220V-73x42x45)

1

29

STATOR (110V/00V-73x42x45)

1

30

MOTOR HOUSING

1

31

CARBON BRUSH HOLDER (7x11)

2

32

CARBON BRUSH (7x11x17)

2

33

BRUSH SPRING (0.35x3x3T)

2

34

PANHEAD MACHINE SCREW (M4x10xP0.7)

2

35

PANHEAD TAPPING SCREW-B (M4x12)

4

36

WIRE (1.25x2Cx65CM-VCTF)

1

37

CABLE PROTECTOR (5/16"x40CM)

1

38

PANHEAD TAPPING SCREW (M4x14)

2

39

CRIMP CAP CONNECTOR (C4)

3

40

MOTOR TAIL CASTING

1

41

PANHEAD TAPPING SCREW (M4x25)

2

42

SLIDE PLATE (L230MM)

1

43

SOCKET CAP SCREW (M6x20xP1.0)

5

44

GEAR RACK (M1.5x150L)

1

45

SOCKET CAP SCREW (M8x16xP1.25)

2

46

THUMB SCREW (M5x16)

3

47

FLAT WASHER (Ø5xØ12x1)

2

48

COOLANT TANK BRACKET

1

49

COOLANT TANK ASSEMBLY

1

50~53 N/A

-

54

TUBE (Ø4xØ6x20CM)

1

55

PANHEAD MACHINE SCREW (M4x8xP0.7)

4

56

SWITCH PANEL (90x110x1.5T)

1

57

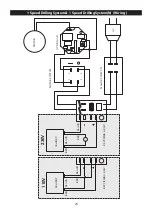

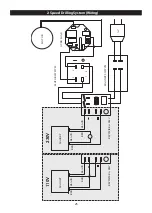

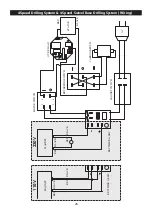

MOTOR SWITCH (110V-220V)

1

58

MAGNET SWITCH (110V&220V)

1

59

SOCKET CAP SCREW (M6x16xP1.0)

1

60

FLAT WASHER (Ø6xØ25x1)

1

61

FLAT WASHER (Ø6xØ40x2.5)

1

62

BUSHING (Ø28xØ32x12)

2

63

CRANK SPINDLE (Ø28)

1

64

CRANK HANDLE

3

65

STAND BODY

1

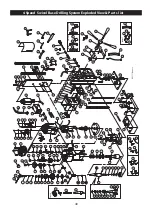

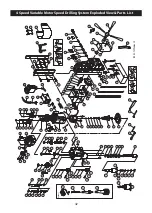

Summary of Contents for MD120/4

Page 44: ......