6

machine for best performance or convenience,

etc.

MOTOR

Always check the nameplate to ensure the A.C.

current supply is the correct voltage for your

machine.

This tool will operate on voltage within plus or

minus 5 percent of that shown on the specification

plate on the tool. Refer to the specification plate on

your tool for proper voltage and current rating.

Do not operate your tool on a current on which the

voltage is not within correct limits.

If an extension cord is used, make sure the

conductor size is large enough to prevent

excessive voltage drop which will cause loss of

power and possible motor damage.

If an extension cord is to be used outdoors, it must

be marked with the suffix WA or W following the

cord type designation. For example – SJTW-A to

indicate it is acceptable for outdoor use. Always

choose the shortest possible cord.

EXTENSION CORD SELECTION

Total Extension Cord Size (AWG)

Cord Length (feet)

25

16

50

12

100

10

150

8

200

6

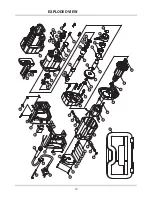

RECIPROCATING SAW

* Storage case

* Blade

* hex wrench

FOREWORD

This Reciprocating Saw is designed for cutting

metal up to 20mm (3/4”) thick, wood up to 300mm

(12") thick (depending on the blade), and various

other materials, such as plastics, fiberglass, hard

rubber, etc.

SELECTING THE BLADE

For best performance, longer blade life, and

smoother cut, select the proper blade for the job.

When cutting metal always select a blade which

will allow at least three teeth to be engaged in the

thickness of material.

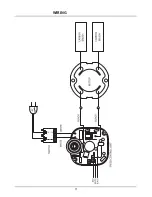

MOUNTING THE BLADE

WARNING: Make sure to unplug the power cord

when mounting or removing the blade.

Warning: Be absolutely sure to hold the flat top

of the blade, instead of the teeth, to prevent

any accident.

The machine is designed that the blade could be

mounted or removed without a wrench or any

other tools.

1.

Press the switch and the shaft will move

forward. Then turn off the switch and unplug

the power cord.

2.

Please turn the quick-release collar as shown .

3.

Turn the quick-release collar to insert the

blade into the small slot of the shaft. The

blade could be mounted either in the upward

or downward direction. When you release the

quick-release collar, the spring will return

automatically.

4.

Pull the blade forth and back for several times

by hand to ensure the blade clicks.