3

KEY

QTY.

DESCRIPTION

A

2

Hex Bolt, 1/4-20 x 1-3/4" Long

B

5

Hex Bolt, 1/4-20 x 1-1/2" Long

C

2

Hex Bolt, 1/4-20 x 1" Long

D

1

Carriage Bolt, 1/4-20 x 3/4" Long

E

9

Nyock Nut, 1/4-20 Thd.

F

6

Flat Washer, 5/16" SAE

G

4

Nylon Washer

H

4

Flat Washer, 5/8"

I

1

Cotter Pin, 5/32" x 2"

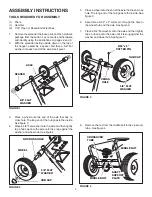

NOT SHOWN FULL SIZE

F

H

I

J

A

B

C

D

E

K

L

M

N

O

Q

P

R

SHOWN FULL SIZE

G

KEY

QTY.

DESCRIPTION

J

1

Cotter Pin, 3/32" x 3/4" Long

K

1

Flow Control Link

L

2

Spacer Tube

M

2

Hub Cap

N

1

Grip

O

1

Vinyl Cap

P

1

Nylon Wing Nut

Q

2

Handle Grip

R

1

Adjustable Stop