9

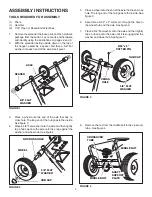

FIGURE 15

CHECK FOR LOOSE FASTENERS

1.

Before each use make a thorough visual check of

the spreader for any bolts and nuts which may have

loosened. Retighten any loose bolts and nuts.

CHECK FOR WORN OF DAMAGED PARTS

2.

Check for worn or damaged parts before each use.

Repair or replace parts if necessary.

CHECK TIRE INFLATION

3.

Check if tires are adequately inflated before each use.

Do not inflate tires beyond maximum recommended

pressure.

1.

Rinse inside of hopper and exterior of spreader and

dry off before storing.

2.

Store in a clean, dry area.

CLEANING

4.

Rinse inside of hopper and exterior of spreader and

dry off before storing.

LUBRICATE

(See figure 15)

5.

Lightly apply automotive grease as needed to the

sprocket and gear.

6.

Oil the nylon bushings on the vertical sprocket shaft

and on the axle at least once a year, or more often as

needed.

7.

Oil right hand (idler) wheel at least once a year or more

often as needed.

MAINTENANCE

STORAGE

GREASE

OIL

OIL

CAUTION: DO NOT

inflate tires beyond the

maximum recommended pressure printed

on side of tire.

REPLACING SLOTTED GEAR

1.

If the axle, slotted gear and sprocket assembly is

disassembled, mark down the positions of the parts

as they are removed. The drive wheel and sprocket

positions in relation to the slotted gear determine

which direction the spreader plate will spin. Be sure

to reassemble them in their original positions. (Refer

to figure 3 on page 4.) Use shim washers (Ref. no. 21

on pages 10 and 11) as needed for minimum backlash.

Add grease to gear and sprocket.

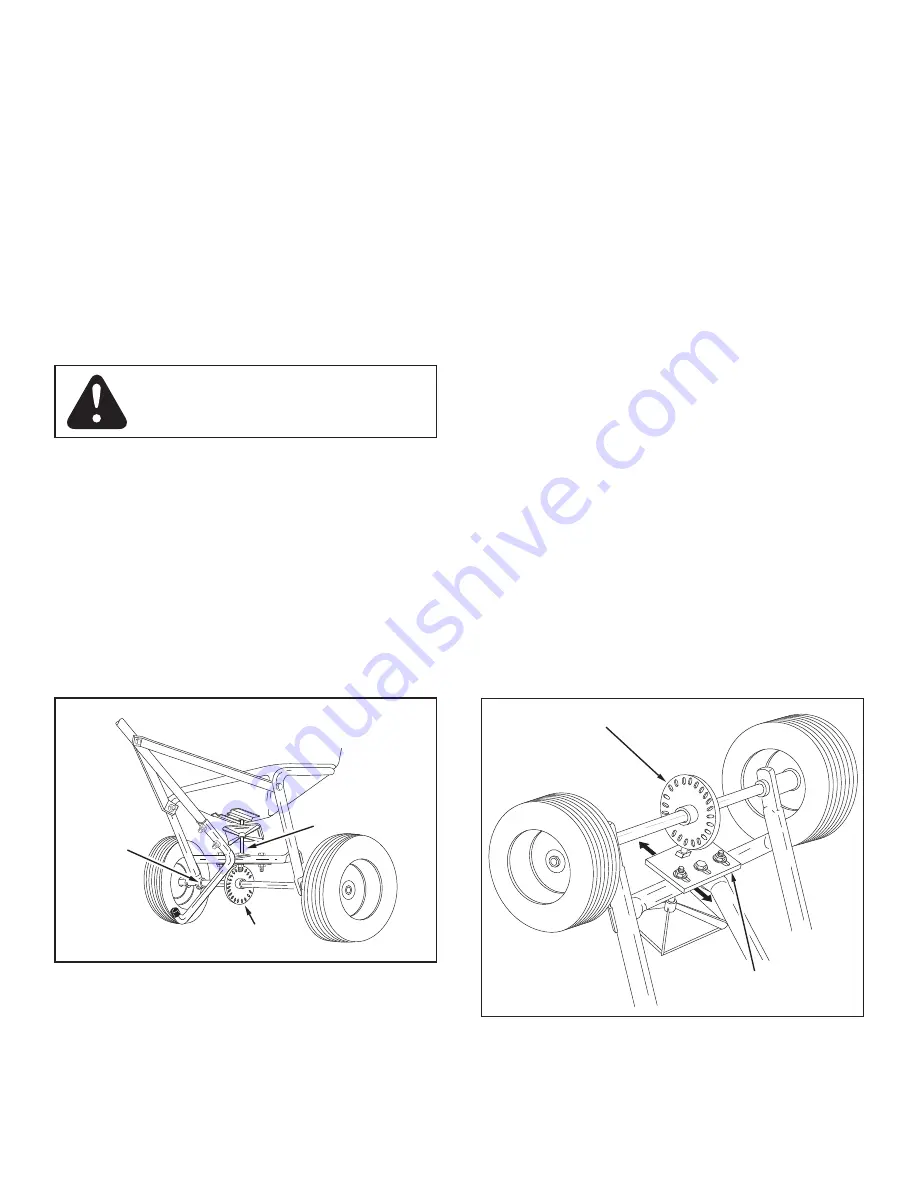

SERVICE AND ADJUSTMENTS

SHAFT SUPPORT PLATE

SLOTTED GEAR

LOCKED UP SPREADER

1.

Turn the spreader over so that the wheels are off the

ground.

2. Loosen all three nuts on the shaft support plate just

enough so that the bolts can be turned easily with a

wrench but cannot be turned by hand.

3. Spin the drive wheel and note how freely it spins and

how much noise the slotted gear makes.

4. To free up the wheel and gear, tap gently on the front

or rear edge of the shaft support plate to move it

slightly forward or backward. You can also tap at the

corners of the plate to angle it slightly.

5. Spin the drive wheel after each adjustment to see if it

spins more freely and if the gear noise is reduced.

6. Continue making slight adjustments until you find the

position where the drive wheel spins most freely and

the gear makes the least noise.

7.

Secure the shaft support plate in this position by

retightening all three nuts that you loosened.

FIGURE 16