9

MAINTENANCE

CLEANING

•

Clean engine as instructed in the engine manual.

•

Clean wheels, finish, etc. Of all foreign matter.

•

Keep finished surfaces and wheels free of all

gasoline, oil, etc.

•

Protect painted surfaces with automotive type wax.

We do not recommend using a garden hose to clean

your unit unless the muffler, air filter and carburetor are

covered to keep water out. Water in engine can result in

shortened engine life.

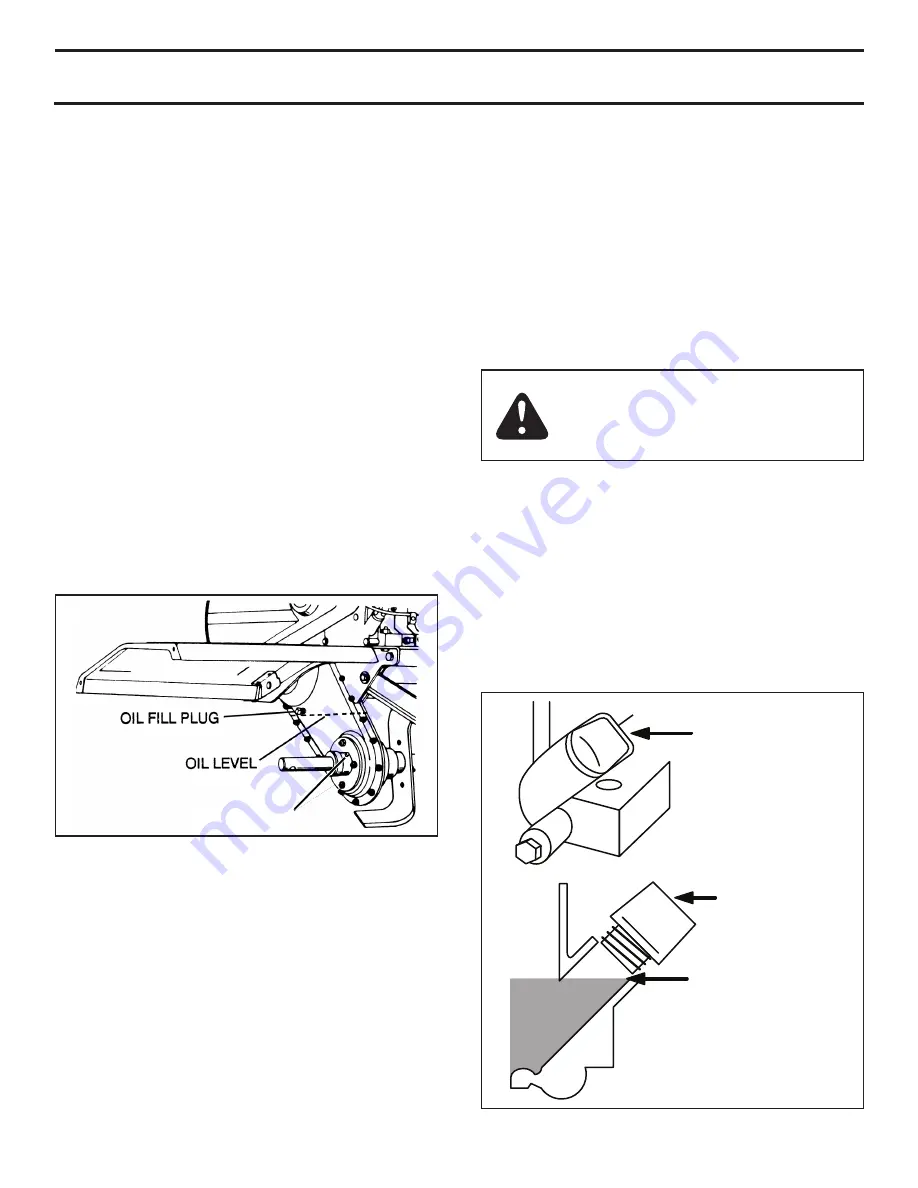

FiGURE 10

FiGURE 11

GREASE FITTING

WARNING:

Always stop engine and

disconnect spark plug wire before cleaning,

lubricating or before performing any repairs

or maintenance.

ENGINE MAINTENANCE

•

Check

oil level

before each use and every 8 hours.

•

Maintain engine oil as instructed in figure 11 below.

•

Service

air cleaner

every 25 hours under normal

conditions. Clean every few hours under extremely

dusty conditions. Poor engine performance and

flooding usually indicates that the air cleaner should

be serviced. To service the air cleaner, refer to the

separate engine manual.

•

Spark plug

replacement is recommended every 100

hours or yearly. Check the engine manual for correct

plug type and gap specifications.

OIL

FULL OIL LEVEL

REMOVE OIL CAP

REPLACE CAP

AFTER FILLED

MUFFLER

Do not operate tiller without muffler. Do not tamper with

exhaust system. Damaged mufflers or spark arresters

could create a fire hazard. Inspect periodically and

replace if necessary. If your engine is equipped with a

spark arrester screen assembly, remove every 50 hours

for cleaning and inspection. Replace if damaged.

TRANSMISSION LUBRICATION

Check the transmission oil level after first 5 hours of

operation. Remove oil fill plug (figure 10). Oil level must

be even with the plug hole (with tiller level). If necessary,

add oil. Use SAE 30 non-detergent motor oil. Replace oil

fill plug.

Check the transmission oil level after each 10 hours of

operation.

NOTE:

It is not necessary to change the oil in this tiller

transmission. If for any reason it must be changed, oil

capacity is 22 oz.

BEARING LUBRICATION

Grease the tine shaft bearings every 8-10 hours. Use a

grease gun to apply about 10 pumps of General Purpose

grease in the grease fittings. Wipe off excess grease that is

forced out of the bearings. For dry and dusty environments,

perform this lubricating procedure more often.