6

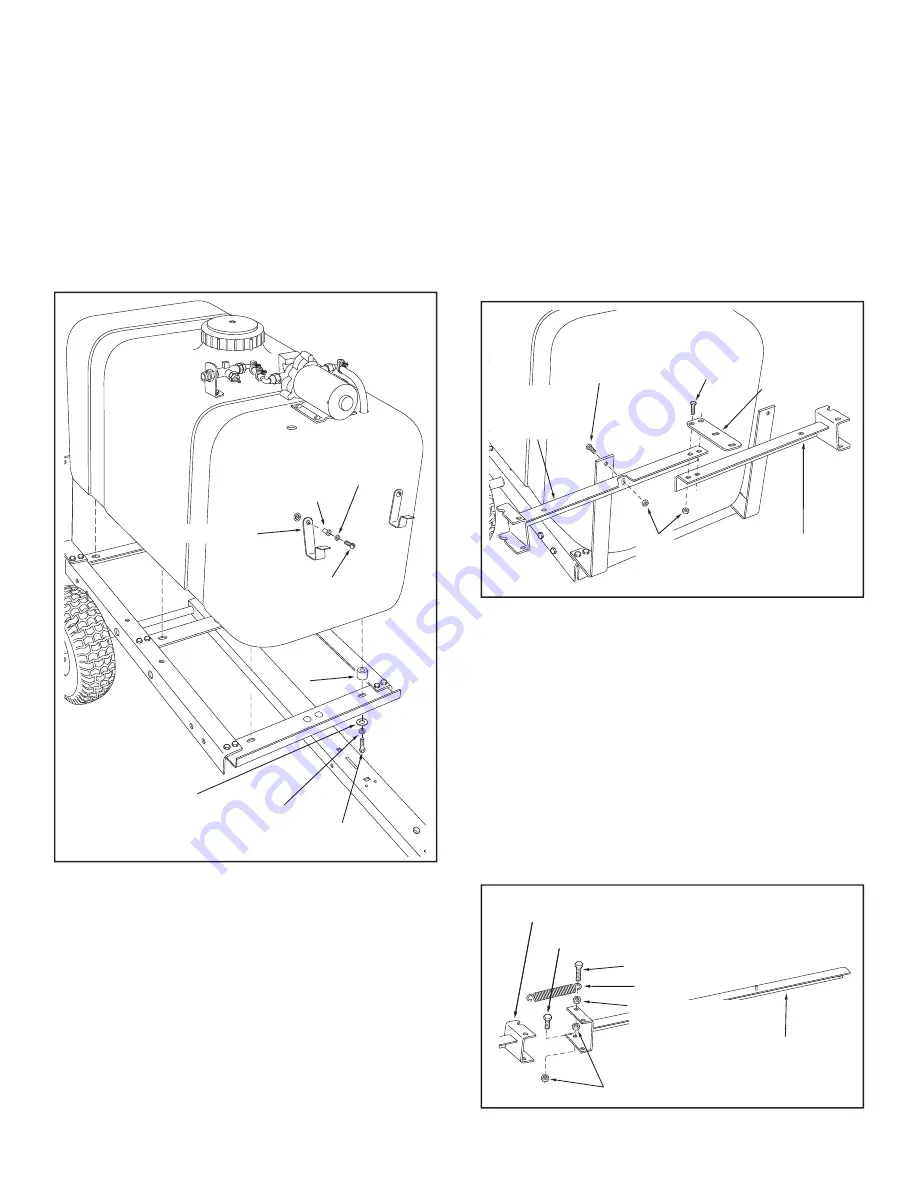

11. Attach the tank to the frame using six 1/2" spacers with

six 3/8" x 1-1/4" hex bolts, 3/8" lock washers and 3/8"

fl at washers. Place the spacers between the tank and

the frame.

Tighten the six bolts until the lock washers

are fl attened. See fi gure 8.

12. Assemble the hose hooks to the front of the tank using

two #10-24 x 1/2" screws, two 3/16" lock washers and

two fl anged spacers.

Tighten the screws until the lock

washers are fl attened. See fi gure 8.

IMPORTANT: Do not overtighten bolts fastening to tank.

Tighten until lock washers are snug and fl attened.

FIGURE 10

13.

Tighten securely the 12 bolts and nuts fastening the

frame strap and the front and rear angles to the side

angles. (Figures 1 and 2)

Tighten only until snug the 2 bolts and nuts fastening

the axle to the frame. (Figure 4)

Tighten securely the 4 nuts fastening the tongue to the

frame. (Figure 3)

FIGURE 8

14. Assemble the (RH) and (LH) boom mount assemblies

to the boom mount brackets using two 5/16" x 3/4" hex

bolts and 5/16" nylock nuts. Fasten through the slotted

hole in each boom mount assembly.

Do not tighten

yet. See fi gure 9.

15. Align the holes in the boom transport bracket with the

holes in the ends of the boom mount assemblies as

shown in fi gure 9. Fasten them together using two 5/16"

x 1" hex bolts and 5/16" nylock nuts.

Tighten the bolts

assembled in this step and in step 14.

NOTE: If the holes in the boom mount assemblies won’t

line up, temporarily loosen the bolts which fasten the boom

mount brackets to the frame.

16. Assemble a 3/8" x 3/4" hex bolt and 3/8" nylock nut to

the hole shown in the bottom of the welded bracket

on the (RH) boom arm assembly.

Tighten. See fi gure

10.

17. Assemble a spring and a 3/8" plain hex nut onto a 3/8"

x 1-1/4" hex bolt. Fasten the bolt to the hole shown in

the top of the welded bracket using a 3/8" nylock nut.

Tighten so that the nylock nut is even with the end of

the bolt. See fi gure 10.

18. Repeat steps 16 and 17 for the (LH) boom arm

assembly.

FIGURE 9

VIEWED FROM REAR

(RH) SIDE VIEWED FROM REAR

1/2" SPACER

3/8" FLAT

WASHER

3/8" LOCK

WASHER

3/8" x 1-1/4"

HEX BOLT

HOSE HOOK

FLANGED

SPACER

3/16" LOCK

WASHER

#10-24 x 1/2"

SCREW

5/16" x 3/4"

HEX BOLT

5/16" x 1"

HEX BOLT

5/16"

NYLOCK

NUTS

(LH) BOOM

MOUNT

ASSEMBLY

BOOM

TRANSPORT

BRACKET

(RH) BOOM

MOUNT

ASSEMBLY

3/8" x 1-1/4" HEX BOLT

3/8" NYLOCK NUT

3/8" x 3/4" HEX BOLT

3/8" PLAIN HEX NUT

SPRING

(RH) BOOM

ARM ASSEMBLY

(RH) BOOM

MOUNT ASSEMBLY

Summary of Contents for 45-0325

Page 14: ...14 NOTES ...

Page 15: ...NOTES ...