9

USING THE SPRAYER

1. Determine the application rate (gallons per 1,000

sq. feet or gallons per acre) based on the chemical

manufacturers recommendations. Use this rate to help

select the pressure setting and tractor speed in the

following instructions.

2. Determine the approximate square footage of the area to

be sprayed and estimate the number of gallons required.

Do not fi ll tank with more solution than needed.

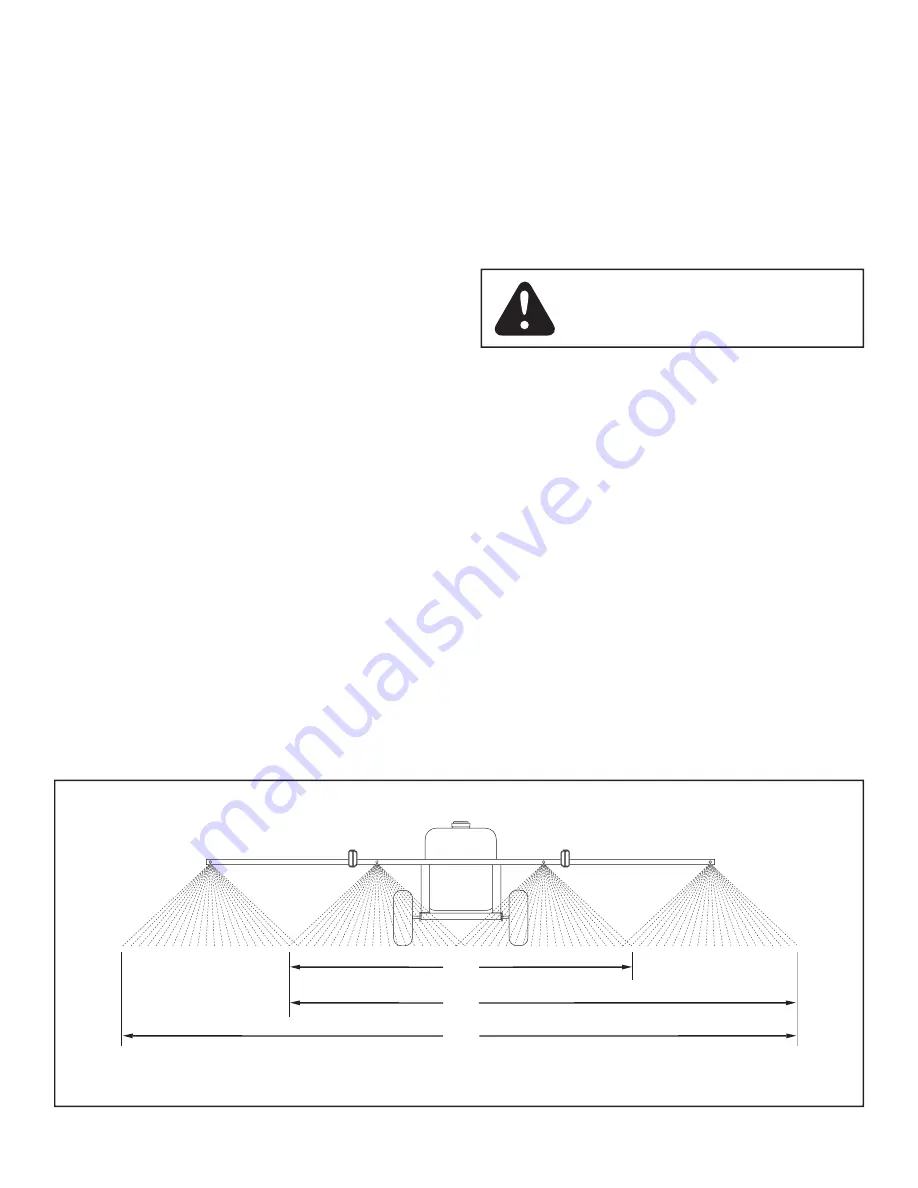

3. Decide how wide a swath you wish to spray with each

pass. Use just the two inside nozzles, or the two inside

nozzles plus one outside nozzle, or use all four nozzles.

The number of square feet covered with each pass will

vary depending on the number of nozzles used, but

the amount of solution applied per square foot will not

vary as long as the same system pressure and speed

of travel are used. Refer to fi gure 18.

FIGURE 18

WIDTH OF SPRAY PATTERN USING 2, 3 OR 4 NOZZLES

CAUTION: Wear eye protection, gloves

and protective clothing when handling and

working with lawn chemicals.

80"

160"

120"

OPERATION

BEFORE STARTING

It is important to test the boom and spray gun with plain

water fi rst to check the sprayer for leaks and to set the spray

pattern and nozzle pressure. If a leak should occur, thread

tape may be used to better seal the fi tting.

PUMP PRESSURE SWITCH

The pump is equipped with a pressure switch. The pressure

switch senses outlet pressure of the pump and will turn off

the electrical power to the pump at a predetermined high

pressure point (45 PSI). If the fl ow demand is very low, the

pump may reach this high pressure point and the switch will

cause "cycling" (the pump cycles on and off rapidly). This is

not a problem unless the pump continuously cycles within

one second intervals for long periods of time.

ADJUSTING OPERATING PRESSURE

The sprayer is equipped with a "Y" fi tting containing two

valves. The bypass valve controls the fl ow to the return

(bypass) hose. The amount of fl ow through the return hose

determines the operating pressure of the boom or the spray

gun. Adjust the bypass valve while either the boom or the

spray gun is in use to obtain the desired pressure, indicated

by the pressure gauge. The tip chart on page 11 shows how

different pressure settings affect boom application rates.

ON-OFF ADJUSTMENT OF BOOM NOZZLES

The boom valve on the "Y" fi tting controls the fl ow to all

the boom nozzles. It should be either completely open or

completely closed. The two valves located on the boom

will turn the fl ow on or off to each outside nozzle. Each

valve should be set either completely open or completely

closed.

ADJUSTING SPRAY GUN NOZZLE

Turn the nozzle on the spray gun to adjust the spray from a

cone shaped fi ne mist to a straight stream. The spray gun

operating pressure should be controlled using the bypass

valve on the "Y" fi tting. Maximum spray gun pressure can

be attained when the boom is shut off.

Summary of Contents for 45-0325

Page 14: ...14 NOTES ...

Page 15: ...NOTES ...