Brush Cutter 4500 Hydro

41

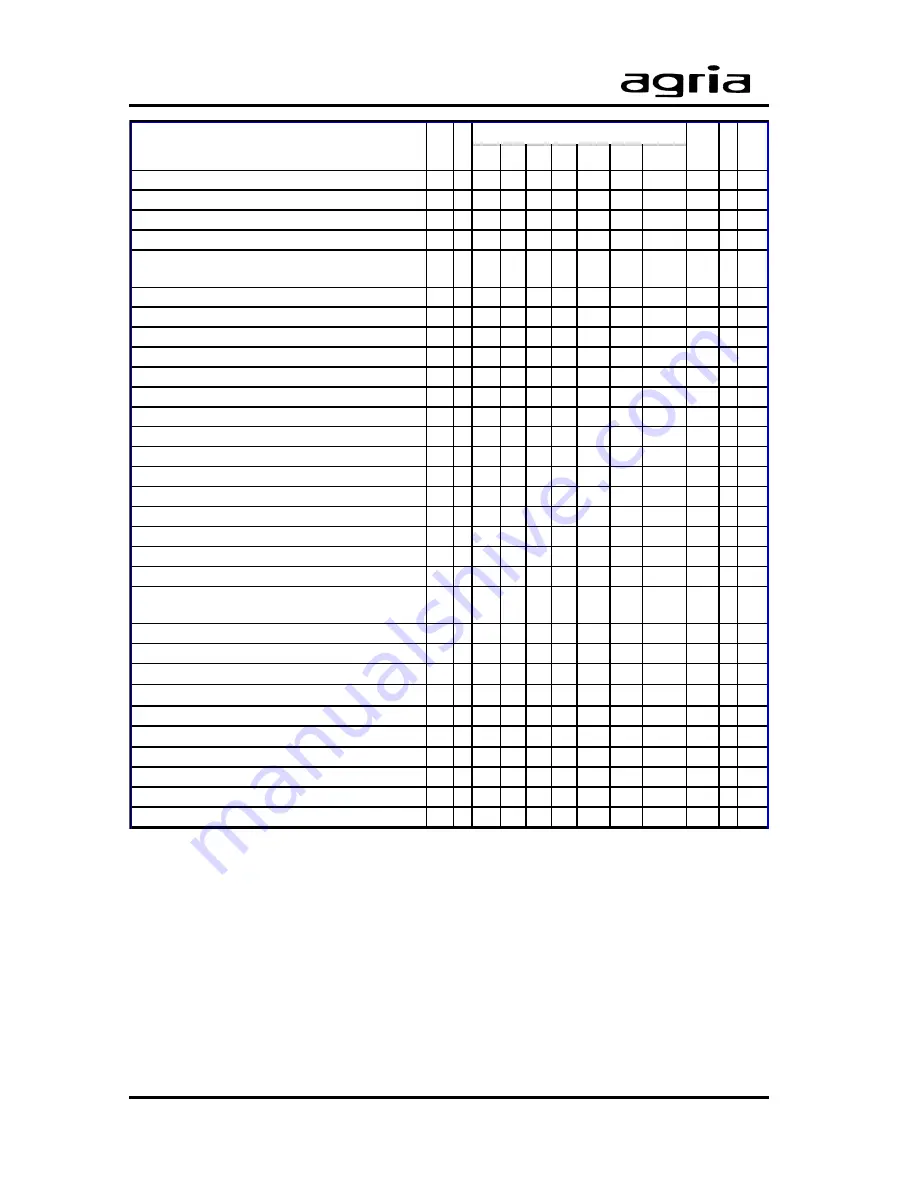

Inspection and Maintenance Chart

P = Item in lubrication chart or maintenance schedule (page 40)

A = Each time before you take up operation

B = After each cleaning, especially with a high-pressure cleaner

J = At least once per year

K = Checks and maintenance to be executed by operator

W = Maintenance to be executed by professional workshop

F = Maintenance should be carried out by your agria workshop

BM = Refer to engine operating instructions

2

8 25 50 100 500 1000

Check safety circuit function

11 K

34

Check engine shut-off switch function

11 K

34

Check cutter brake for proper function

16 K

34

Check brake

10 K

33

Check tarpaulin guard and rubber cap

strips

15 K

32

Check air filter

3 K

BM

Clean cooling-screen

4 K

31

Tighten wheel screws

13

K

36

Clean surrounding parts of exhaust

7 K

K

31

Check engine oil level, refill, if necessary

1 K

K

30

Check bolts and nuts

K

38

Cleaning

K

38

Check V-belt

17

K

35

Clean spark plug and adjust

6

K

BM

Change engine oil

2

W

W

30

Clean air filter

3

W

BM

Check the knives for wear

14

W

W

37

Check the cutter coasting time

16

W

34

Lubricate knife shaft bearing

18

K

K

K

36

Lubricate front frame bearing

18

K

K

36

Clean guide plates, cooling fins –

earlier, if required

F

F

31

Change engine oil filter (only vers. 85 cm)

8

W

30

Replace spark plug

K

BM

Adjust valve clearance

F

BM

Clean cylinder head

F

BM

Replace fuel filter

5

W

30

Replace fuel hoses

F

BM

Lubricate all sliding parts

K

K

38

Lubricate driving chains

12

W W 35

Check hydrostat cooling fan

9

W

32

Lubricate front wheels

16

K

36

p.

B

J

A

P

A f ter operating hours