42

agria

Tool Carrier 5500 Grizzly

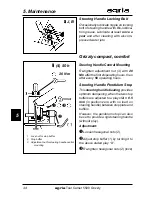

Cleaning the Cylinder Head

After every 400 hours of operation take

off cylinder head and remove carbon

deposits on the cylinder head, piston

crown and valves with a steel brush.

Afterwards, clean with soft brush. Ex-

change the gasket and reassemble it to

the cylinder head. Tighten cylinder head

screws in turn at 25 Nm.

è

-

Service

ç

Readjusting the Valve Lash

After every 400 hours of operation, re-

adjust the valve lash. Intake and outlet

valve are at 0.08–0.11 mm when the

engine is cold.

è

-

Service

ç

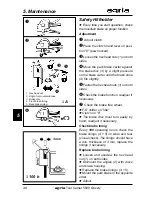

Cleaning the carburettor

Clean the carburettor every 400 operation

hours and then readjust the idle speed.

è

-

Service

ç

Idle speed adjusting

Always ensure that idling-speed is ad-

justed correctly. With the speed control

lever set to idle, the engine is supposed

to run smoothly and without run-out at

low engine speed.

At low speeds, the engine is supposed

to continue running smoothly when the

speed control lever is at a stop in idling.

Adjust the engine speed while the en-

gine is still warm from operation. For this

purpose, readjust the limiter screw (2)

and the mix control screw (1) for idling

speed. Then turn the attachment or ad-

justing screw to adjust the throttle ca-

ble for no play. (For idling speeds refer

to “Specifications”).

Adjustment

è

-

Service

ç

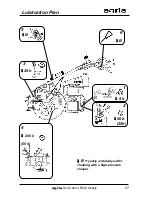

Governor

For proper function of the engine speed

governor and to adjust the upper idling

speed, the governor spring has to be in

the appropriate hole, see fig.

W

Any changes to the position of

the spring increases the risk of

accident and will render the warranty

and type approval null and void!

Keep governor spring, lever and linkages

free from dirt and plant trash at all times.

5

1 Idling speed mix control screw

2 Idling speed control screw

3 Idling speed air jet

Engine

EH 34 D

Engine

EH 25 D

Motor EH 34 D

Reglerfeder in

Loch 3 und B

Engine EH 25 D

Governor spring

in hole 2

5. Maintenance

Petrol engine