agria

Tool Carrier 5500 Grizzly

49

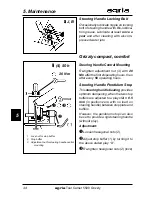

5. Maintenance

General Maintenance

Every time

y

ou take up operation watch

out for fuel and oil leakage, repair if neces-

sary.

Regularly check bolts and nuts for tight fit,

re-tighten, if necessary.

After every 50 operating hours, at least once

a year and after cleaning:

Lubricate all gliding and moving parts with

Bio-lubricating grease or Bio-lubricating oil

(e.g. speed control lever, handle bearing etc.).

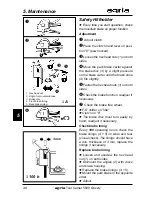

Cleaning

Engine

Clean engine only with a cloth. Avoid spray-

ing with water jets, as water might penetrate

into ignition and fuel system and cause mal-

functions.

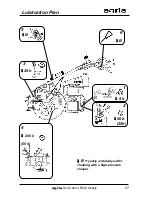

Machine

After each cleaning (spraying with water,

expecially with air-compressed water jets)

lubricate all lubrication points, oil and let

tool carrier run for a short time to press

water out.

Apply grease generously to leave a grease

ring around bearings to prevent water, plant

sap, and dirt from penetrating.

è

I

5