9

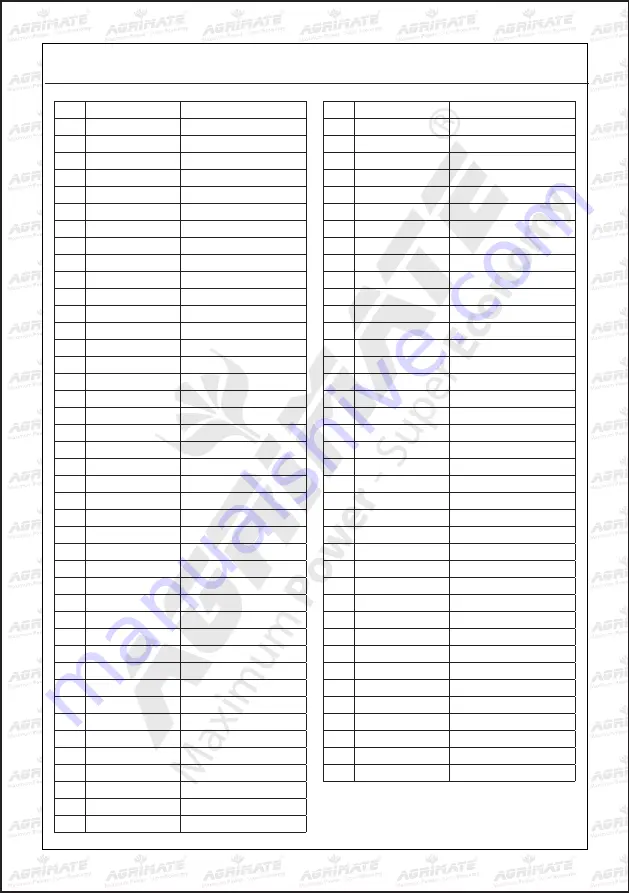

ENGINE SPARE PARTS LIST OF AM-P768-PRO

S.N. Part No.

Description

1

AMP 768 PRO E01

SCREW

2

AMP 768 PRO E02

CLEANER OUTSIDE COVER

3

AMP 768 PRO E03

CLEANER ELEMENT

4

AMP 768 PRO E04

SCREW M5X55

5

AMP 768 PRO E05

CLEANER INSIDE COVER

6

AMP 768 PRO E06

SCREW ST4.2X12-F-H

7

AMP 768 PRO E07

CHOKE

8

AMP 768 PRO E08

CHOKE HANDLE

9

AMP 768 PRO E09

CARBURATOR

10

AMP 768 PRO E10

GASKET

11

AMP 768 PRO E11

SCREW M5X20

12

AMP 768 PRO E12

INLET MANIFOLD

13

AMP 768 PRO E13

CYINDER WASHER

14

AMP 768 PRO E14

ANNUL B3X10

15

AMP 768 PRO E15

SCREW M4X16

16

AMP 768 PRO E16

FAN COVER

17

AMP 768 PRO E17

CLUTCH STEP SCREW

18

AMP 768 PRO E18

WASHER

19

AMP 768 PRO E19

CLUTCH SHOE COMP.

20

AMP 768 PRO E20

WASHER

21

AMP 768 PRO E21

CLUTCH SPRING

22

AMP 768 PRO E22

NUT M8X1

23

AMP 768 PRO E23

WASHER 8

24

AMP 768 PRO E24

STOP CORD COMP

25

AMP 768 PRO E25

CLIP

26

AMP 768 PRO E26

PRIMARY CORD GROMMET

27

AMP 768 PRO E27

MAGNETO STATOR

28

AMP 768 PRO E28

MAGNETO ROTOR

29

AMP 768 PRO E29

SCREW M5X25

30

AMP 768 PRO E30

FRONT HALF CRANK CASE

31

AMP 768 PRO E31

GUIDE PLATE

32

AMP 768 PRO E32

CRANK CASE GASKET

33

AMP 768 PRO E33

OIL SEAL

34

AMP 768 PRO E34

BALL BEARING 6001/P5

35

AMP 768 PRO E35

KEY

36

AMP 768 PRO E36

CRANK SHAFT COMP.

37

AMP 768 PRO E37

REAR HALF CRANK CASE

38

AMP 768 PRO E38

STARTER PULEEY ASS’Y

39

AMP 768 PRO E39

STARTER PAWL SPRING

40

AMP 768 PRO E40

STARTER PAWL

41

AMP 768 PRO E41

SCREW M5X10

42

AMP 768 PRO E42

RECOIL SPRING

S.N. Part No.

Description

43

AMP 768 PRO E43

STARTER ROPE REEL

44

AMP 768 PRO E44

RECOIL STARTER BODY

45

AMP 768 PRO E45

ROPE GUIDE

46

AMP 768 PRO E46

ROPE

47

AMP 768 PRO E47

STARTER HANDLE

48

AMP 768 PRO E48

GASKET

49

AMP 768 PRO E49

SCREW M5X14

50

AMP 768 PRO E50

COVER

51

AMP 768 PRO E51

COVER

52

AMP 768 PRO E52

SCREW M4X12

53

AMP 768 PRO E53

PLUG CAP

54

AMP 768 PRO E54

CLICK SPRING

55

AMP 768 PRO E55

PLUG COVER

56

AMP 768 PRO E56

SPARK PLUG

57

AMP 768 PRO E57

SCREW M5X20

58

AMP 768 PRO E58

GASKET

59

AMP 768 PRO E59

MUFFLER COMP.

60

AMP 768 PRO E60

SCREW M5X50-10.9

61

AMP 768 PRO E61

CYLINDER

62

AMP 768 PRO E62

CYLINDER WASHER

63

AMP 768 PRO E63

PISTON RING

64

AMP 768 PRO E64

PISTON

65

AMP 768 PRO E65

PISTON PIN

66

AMP 768 PRO E66

NEEDLE BEARING

67

AMP 768 PRO E67

PISTON PIN CIRCLET

68

AMP 768 PRO E68

FUEL TANK LID

69

AMP 768 PRO E69

GASKET

70

AMP 768 PRO E70

AIRINLET MOUTH

71

AMP 768 PRO E71

INSIDE COVER

72

AMP 768 PRO E72

CASING

73

AMP 768 PRO E73

CHAIN

74

AMP 768 PRO E74

FUEL PIPE

75

AMP 768 PRO E75

FUEL PIPE

76

AMP 768 PRO E76

PLUG

77

AMP 768 PRO E77

CLEANER

78

AMP 768 PRO E78

FUEL TANK LID

79

AMP 768 PRO E79

SCREW M5X16

80

AMP 768 PRO E80

STARTER PULLEY ASSY

81

AMP 768 PRO E81

STARTER

Summary of Contents for AMP-768-PRO 4S Series

Page 6: ...6 STAND DIAGRAM OF AMP 768 PRO AMP 968 PRO ...

Page 8: ...8 ENGINE SPARE PARTS DIAGRAM OF AM P768 PRO ...

Page 10: ...10 TANK PUMP SPARE PARTS DIAGRAM OF SPRAYER AMP 768 PRO AMP 968 PRO ...

Page 18: ...18 Small Maintenance Big Savings Small Maintenance Big Savings Small Maintenance Big Savings ...