7

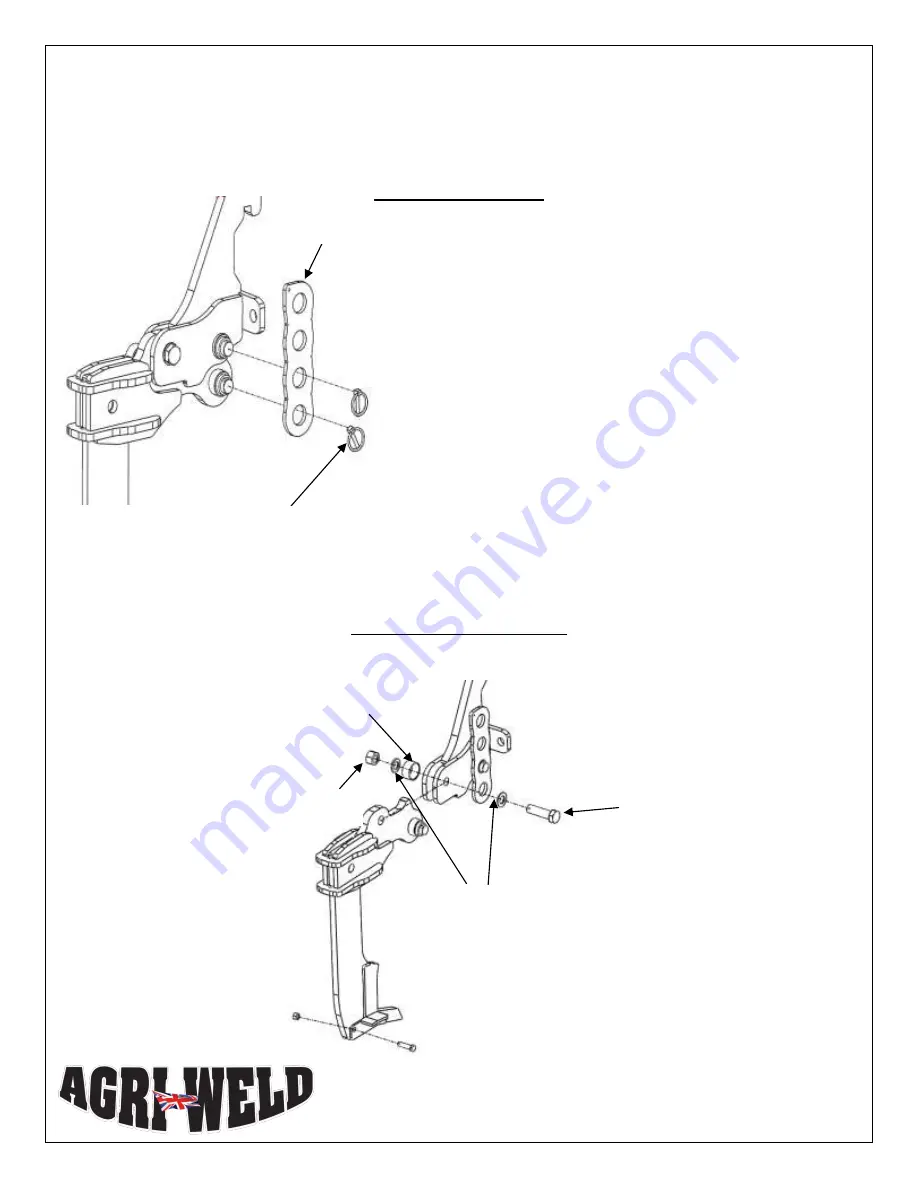

Replacing Snap Bar

SAFETY FIRST:

When replacing the snap bar after shearing, ensure the legs

are raised just out of work sufficiently so that the leg falls into

position to allow the snap bar to be replaced. The tractor

should be stationary and the engine turned off to ensure the

operator is safe to perform the adjustments required. No tools

are needed and replacing the snap bar is a single man

procedure.

TO REPOSITION SNAP BAR:

Remove both linch pins, take off and dispose of broken piece.

Relocate remaining snap-bar to the next available position. Re-

fit Linch pins and continue.

Leg Socket Pivot

Bush

M24 x 100

M24 Washer

M24 Nylock Nut

8mm Linch Pins

Snap Bar

Hook On Shear Leg Assembly

Summary of Contents for 3M MINDISC

Page 1: ...1 OPERATOR MANUAL 3M MINDISC ...

Page 11: ...11 Scraper Mount Assembly M12 x 40 Cuphead Squares M12 nut M12 washer Scraper Scraper mount ...

Page 14: ...14 ...

Page 15: ...15 ...

Page 16: ...16 ...