AG-tronik M1 AND REGULATOR PR-9

INSTRUCTIONS FOR USE – rev. 2017-04

64

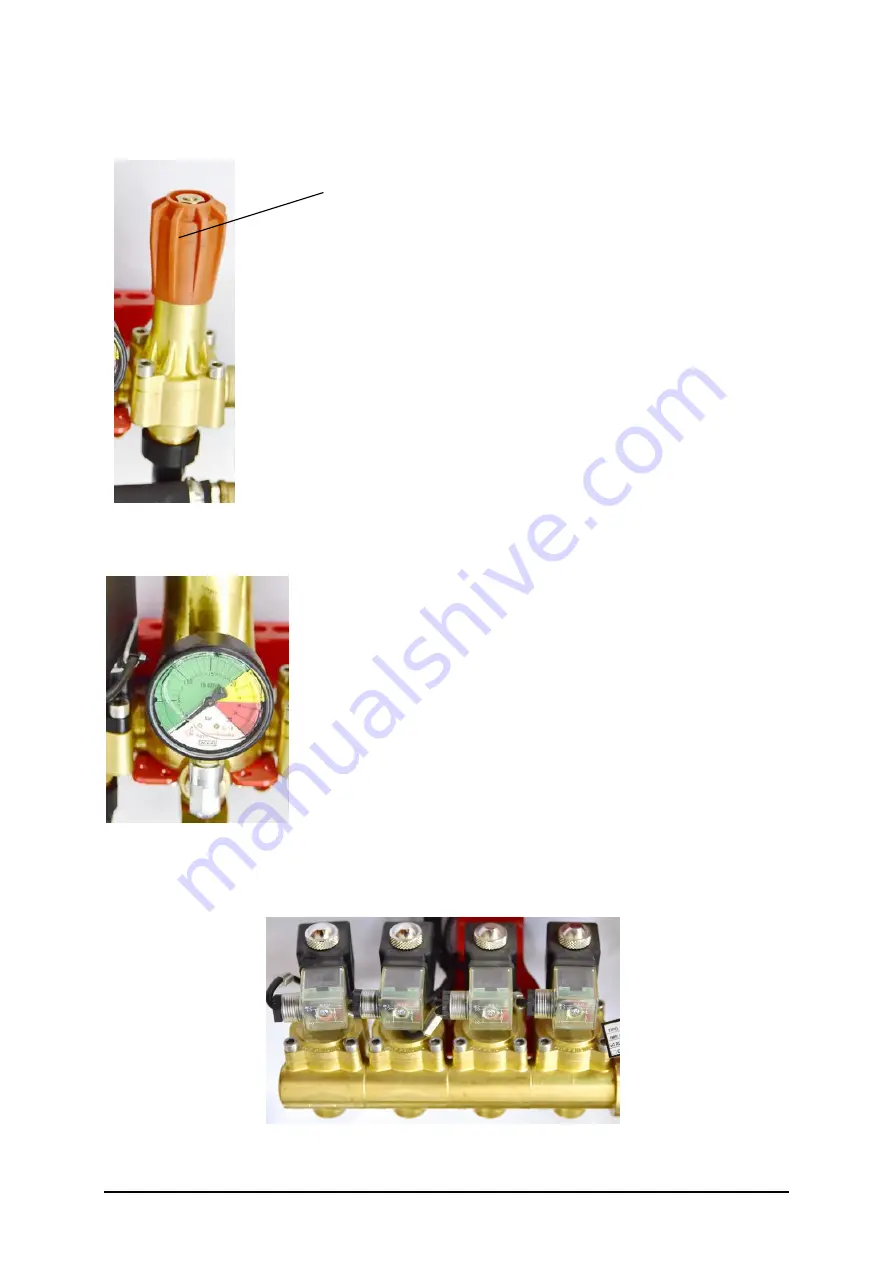

15.3. Manual regulation valve

Regulating nut

Manual regulation valve is for manual settings of

maximum pressure in system, that is in sprayer. In fact this

is safety valve, which can be adjusted with the nut. The

pressure is increasing by turning the nut in clock wise

direction and vice versa. The control of pressure is 0–20

bar.

Figure 112

15.4. Pressure gauge

As standard, pressure regulator is fitted with pressure gauge

with diameter of 63 mm, class 1.6. Measurement range is 0–30

bar. The scale is divided into a colour ranging from 0–20 bar

in green, 20–25 bar is yellow and 25–30 bar is in red.

Pressure gauge is filled with glycerine, which stabilizes the

indicator. During winter time, it is recommended to unscrew

pressure gauge and store it in a warm place, if the sprinkler is

exposed to temperatures below freezing point.

As additional equipment, regulator can be fitted with larger

pressure gauge with diameter of 100 mm.

Figure 113

15.5. Distribution valve EM

Figure 114