INSTRUCTIONS FOR USE

AGP 300 – 600 PRO

Rev.02/2019

48

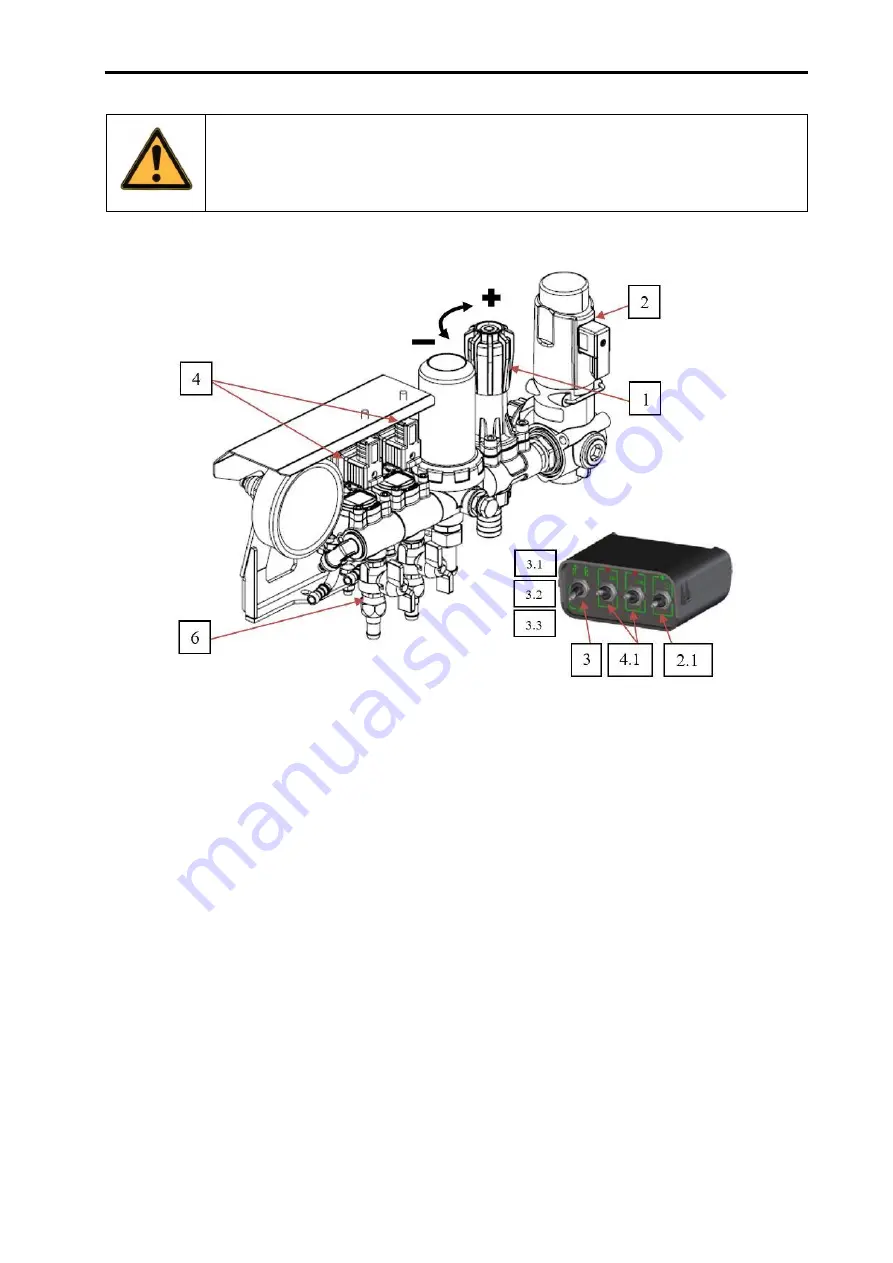

10.5.2

Remote pressure regulator (PR8ECF/2EC)

Figure 10.11

Through the control panel with the main switch in position (3.2 or 3.3) and closed ball valves for

mixing (6) on the regulator. Using the switch (2.1) on the control panel, increase the max. pressure

(hold the switch for 30 seconds). By means of a manual control valve (1) on the pressure regulator,

adjust the maximum system pressure (0-20 bar).

Through the control panel for remote operation (the switch is in position 3.1) open the diverter

valves supplying the spraying nozzles (4) and the ball valve (6) for mixing.

Using the switch (2.1) on the control panel, adjust the desired operating pressure value according

to the calculation. The operating pressure can also be adjusted during driving.

10.6

Pressure regulator maintenance

After each spraying, the regulator must be washed using clean water. The spray residues cause

additional corrosion of seals in the regulator, thereby reducing their life span. This maintenance

should be performed in accordance with instructions for complete or partial cleaning of the

machine, which are specified in a special chapter of these Instructions for use.

Here are some additional instructions for maintenance of individual machine components:

•

It is recommended to grease all the sealing joints containing round gaskets.

WARNING: When adjusting the operating pressure, be careful to ensure

that the engine rpm speed matches the rpm speed, based on which you have

selected the speed of operation!