© 2006-Present Agrowtek Inc.

www.agrowtek.com

| 200 N Anets Dr. Northbrook, IL 60062 | help@agrowtek.com

11

CO

2

Control

CO2 can be operated by an internal injection cycle timer or by PPM sensor control. To operate by PPM sensor, plug the sensor

cable into one of the two sensor cable ports. When the CO2 sensor is connected, the internal injection timer is disabled.

CO2 is dispensed only when the controller is in “day” mode.

When using the injection/interval timers, CO2 is dispensed in a cycle of MM:SS on, and MM:SS off.

The hysteresis is added the set point and acts as the point at which the controller ceases to operate CO2.

Ventilation Interrupt:

CO2 will not dispense when the ventilation output is active.

If the temperature or humidity rises above either set point, the CO2 cycle will be cancelled until the conditions return to

acceptable levels. If a time is set in the “Ventilation Delay” timer then ventilation will be prevented until the time has been

reached.

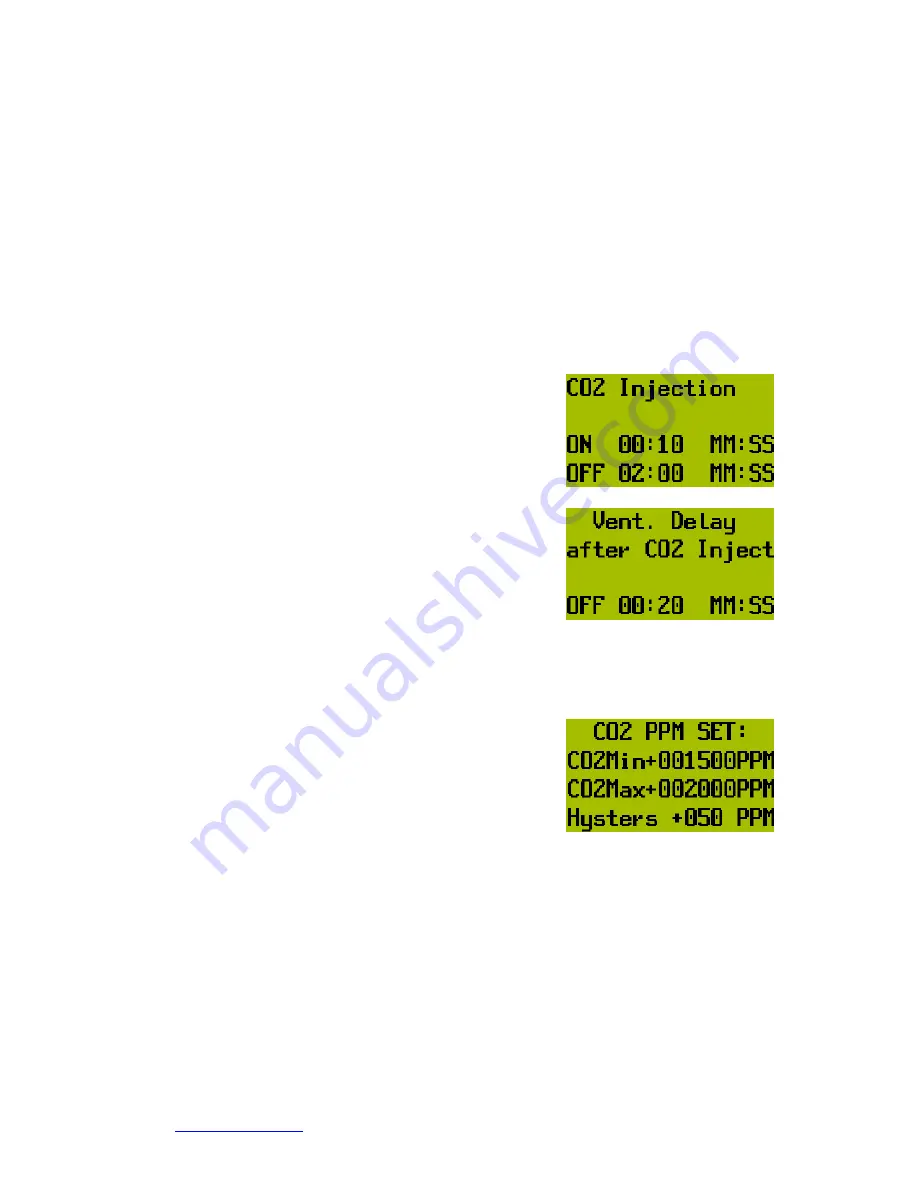

Timer Based Operation

CO2 On Time: The time in MM:SS for the solenoid valve (or CO2

generator) to remain on.

CO2 Off Time: The time in MM:SS between CO2 emission cycles.

Vent. Delay after CO2 Inject: The time in MM:SS to prevent

ventilation equipment from activating after the “CO2 Inject ON” Time

has completed.

Acceptable Values: 00:00 to 99:59

PPM Sensor Based Operation

To operate CO2 equipment based on the PPM sensor, connect the

sensor to either sensor cable port. Navigate to the “Climate Setup”

menu and set the CO2 PPM set point and hysteresis.

The “Vent Delay after CO2 Inject” timer will operate each time the CO2

output is activated.

Acceptable Values: +000000 to +002000

Notice!

Entering a “min” value greater than 2000ppm will cause CO2 to operate continuously!

Entering a “max” value greater than 2000ppm will prevent Ventilation from activating due to high CO2 level!

(Ventilation will continue to operate for high temperature/humidity.)

Main Menu -> Timer Setup

Main Menu -> Climate Setup

CO2 Injection Timer

CO2 Ventilation Delay after Injection

CO2 PPM Set point & Hysteresis