6.1

11.2 11.1 10.3

11.1

7,4

7.1/7.2/7.3

3.1/3.2/3.3/3.4/4.1/10.1/10.2

5.1 5.2

4.2

5.1 5.2

2.1/2.2/2.3/2.4/2.5/2.6/4.1

1.1/1.2/1.3

11.1

9.1

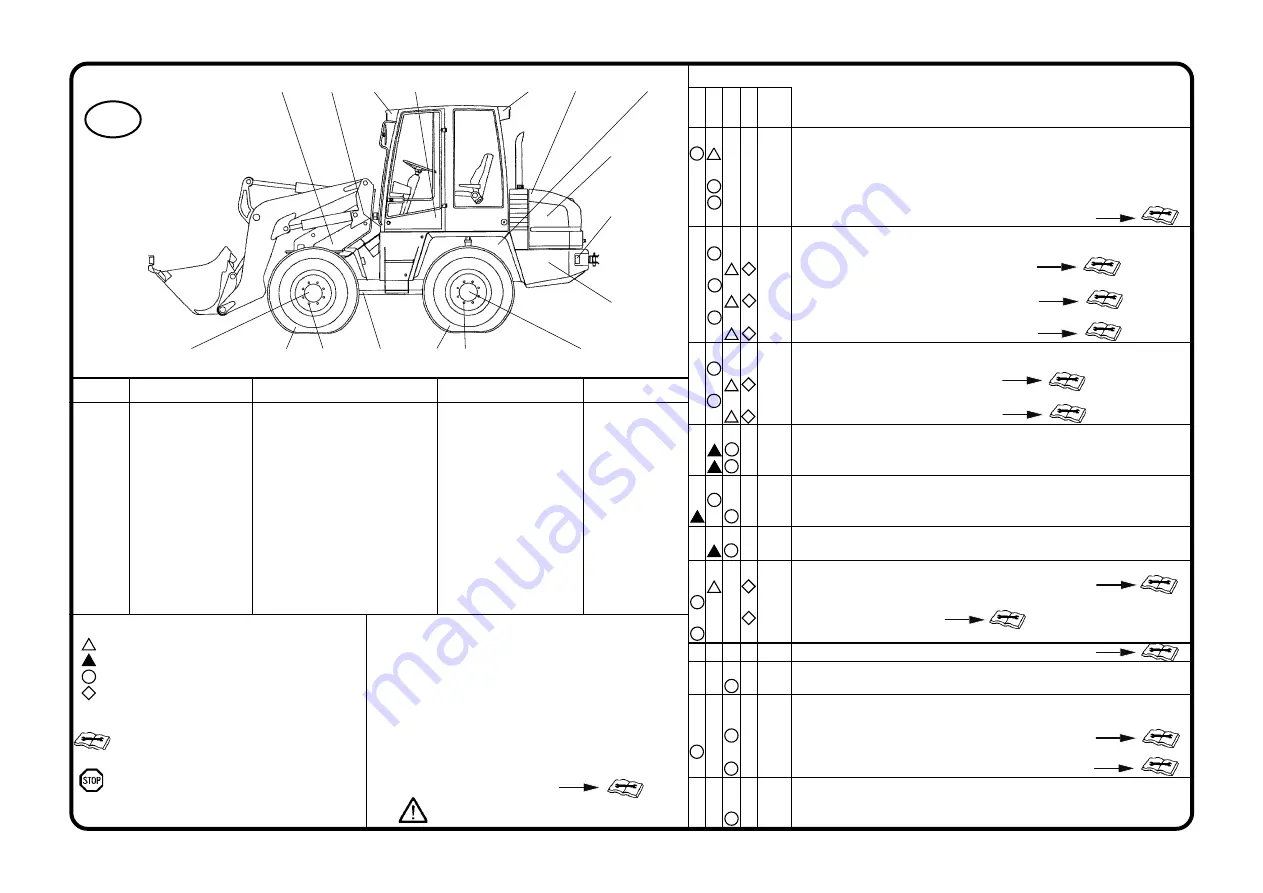

GB

Item Designation

Specification

Viscosity

Filling amount

1

Motor oil

MIL-L-2104 C = API-CD

acc. to manufacturer

ca. 10 l with oil filter

2.2

Transmission oil

MIL-L-2105 D = API-GL5-6

SAE 85 W 90

ca. 4.5 l

2.4

Transmission oil

MIL-L-2105 D = API-GL5-6

SAE 85 W 90

ca. 2x 0.5 l

2.6

Transmission oil

MIL-L-2105 D = API-GL5-6

SAE 85 W 90

ca. 0.5 l (20 km/h)

ca. 3.0 l (30 km/h)

3.2

Transmission oil

MIL-L-2105 D = API-GL5-6-LS SAE 85 W 90-LS

ca. 3.0 l

with LS additive

3.4

Transmission oil

MIL-L-2105 D = API-GL5-6

SAE 85 W 90

ca. 2x 0.5 l

7.3

Hydraulic oil (4)

DIN 51524, HVLP 46

ISO VG 46, VI > 180

ca. 120 l

8

Grease

DIN 51825 - KPF 1/2 N-20

as required

9

Distilled water

as required

10

Mineral oil

DIN 51524, HVLP 46

ISO VG 46, VI > 180

as required

10

50

500

1500

Item

Every x operating hours

max. permitted intervals or

shorter (depending on use)

*

Maintenance points

1.

Engine

1.1

Maintenance according to manufacturer's regulations

1.2

Dry air filter system

Activate dust removal valve

Check maintenance display

1.3

Replace filter element if maintenance display is red

2

Rear axle with axle power shift gear or gear shift

2.1

Check oil level in axle gear (control screw)

2.2

Change oil in axle gear

2.3

Check oil level in planetary gear (control screw)

2.4

Change oil in planetary gear

2.5

Check oil level in power shift gear (control screw)

2.6

Change oil in power shift gear

3

Front axle

3.1

Check oil level in axle gear (control screw)

3.2

Change oil in axle gear

3.3

Check oil level in planetary gear (control screw)

3.4

Change oil in planetary gear

4

Axles / cardan shaft(s)

4.1

Check fastening of axles (385Nm)

4.2

Check fastening of cardan shaft(s) (32 Nm)

5

Wheels and tyres

5.1

Check air pressure

5.2

Check fastening of wheel nuts (385 Nm)

6

Ball bearing slewing ring (swivel loader only)

6.1

Check fastening (300 Nm)

7

Hydraulic system

7.1

Replace filter inserts, observe electric control lamp

7.2

Oil level check (view glass)

7.3

Oil change

7.4

Check and clean hydraulic oil cooler

8

Lubrication points (indicated in red)

9

Battery

9.1

Visual check

10

Brake system

10.1 Service and parking brake: Take function and visual check before starting work

10.2 Service brake: check brake lining, adjust if necessary

10.3 Service brake: visually check compensation tank

10.3 Parking brake: check and adjust if required

11

Lighting system / fresh air filter

11.1 Take function test before starting work

11.2 Check fresh air filter

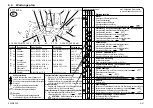

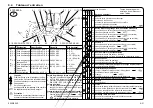

Lubrication points (indicated in red)

1. Lubricate bolts every 10 operating hours with

grease acc. to DIN 51825 - KPF 1/2 N-20.

2. Lubricate glide points as required and always

after cleaning, using grease acc. to DIN 51825 -

KPF 1/2 N-20.

Oil lubrication points

3. Lubricate joints and toggle levers every 50

operating hours wih engine oil MIL-L-2104 C.

Optional features: Biodegradable hydraulic oil

4. Ester-based synthetic hydraulic oil. Viscosity

class ISO VG 46 VI > 180

CAUTION

Use only mineral oil for the

service brake!

Key to symbols

First oil change / first filter replacement

first check; eliminate any determined problems

Check; eliminate any determined problems

Change

The markings, filling and check plugs

are binding

Refer to operating instructions

Caution

When carrying out maintenance work, heed

the accident prevention regulations!

**

*

*

*

*

*

*

4102177A

8.4

Maintenance Plan

8-21

S05D/S06D

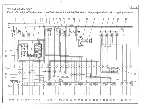

Summary of Contents for AF 100

Page 61: ...F08D F10D F08D F10D Beschilderung Beschilderung Signalisation Signalisation Signs Signs ...

Page 76: ...F08D F10D F08D F10D 2 8 2 8 Schriftzug Lärmarme Baumaschine Schriftzug Lärmarme Baumaschine ...

Page 104: ...F08D F10D F08D F10D Beschreibung Beschreibung Description Description Description Description ...

Page 177: ...F08D F10D F08D F10D Wartung Wartung Entretien Entretien Maintenance Maintenance ...

Page 219: ...F08D F10D F08D F10D Störung Ursache und Abhilfe Störung Ursache und Abhilfe ...

Page 222: ...F08D F10D F08D F10D Dérangements causes et remèdes Dérangements causes et remèdes ...

Page 225: ...F08D F10D F08D F10D Malfunctions causes and remedies Malfunctions causes and remedies ...

Page 228: ...Anhang Anhang Appendice Appendice Appendices Appendices ...

Page 229: ......

Page 230: ......

Page 237: ......

Page 242: ...F08D F10D F08D F10D A 10 3 A 10 3 ...

Page 243: ...F08D F10D F08D F10D B 10 3 B 10 3 ...

Page 244: ...F08D F10D F08D F10D C 10 3 C 10 3 ...

Page 245: ...F08D F10D F08D F10D D 10 3 D 10 3 ...

Page 246: ...F08D F10D F08D F10D E 10 3 E 10 3 ...

Page 247: ...F08D F10D F08D F10D F 10 3 F 10 3 ...