K65E/K75D/K95D/K95i

1-11

K65E/K75D/K95D/K95i

1-11

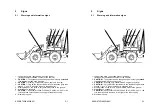

During maintenance and repair

work under the bucket arm:

- the bucket arm support must be

removed after loosing of the fixing

bolt (1-1/arrows)

- the bucket arm must be suppor-

ted (1-2/arrow) and

- the ball block valve for working

and additional hydraulic (1-3/

arrow) must be closed.

1.5.2.6

Fix the articulated link

form-locking during maintenance

and repair work. Remove the bend

in protection after loosing of the

fixing screw, insert the bend in

protection into the articulated link

and fasten it (1-4/arrow).

1.5.2.7

If necessary, protect the

maintenance area on a large scale.

1.5.2.8

The machine must be

protected from unintentionally

starting after it was switched off for

maintenance and repair work:

- remove the ignition key

- attach warning sign at battery

main switch, if installed.

This applies especially to works to

the electrical equipment.

1.5.2.9

Individual pieces and

large assemblies must be carefully

secured to hoisting equipment when

being substituted to avoid any

damage. Only suitable and tech-

nical sound hoisting equipment may

be used as well as crane equipment

with adequate payload. Do not stand

or work underneath suspended

loads!

1.5.2.10

Only experienced per-

sonnel should be entrusted with the

securing of loads!

Loads must be secured so that they

cannot slip or fall down.

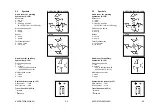

During maintenance and repair

work under the bucket arm:

- the bucket arm support must be

removed after loosing of the fixing

bolt (1-1/arrows)

- the bucket arm must be suppor-

ted (1-2/arrow) and

- the ball block valve for working

and additional hydraulic (1-3/

arrow) must be closed.

1.5.2.6

Fix the articulated link

form-locking during maintenance

and repair work. Remove the bend

in protection after loosing of the

fixing screw, insert the bend in

protection into the articulated link

and fasten it (1-4/arrow).

1.5.2.7

If necessary, protect the

maintenance area on a large scale.

1.5.2.8

The machine must be

protected from unintentionally

starting after it was switched off for

maintenance and repair work:

- remove the ignition key

- attach warning sign at battery

main switch, if installed.

This applies especially to works to

the electrical equipment.

1.5.2.9

Individual pieces and

large assemblies must be carefully

secured to hoisting equipment when

being substituted to avoid any

damage. Only suitable and tech-

nical sound hoisting equipment may

be used as well as crane equipment

with adequate payload. Do not stand

or work underneath suspended

loads!

1.5.2.10

Only experienced per-

sonnel should be entrusted with the

securing of loads!

Loads must be secured so that they

cannot slip or fall down.

Summary of Contents for AL 100t

Page 9: ...Safety regulations...

Page 30: ...Signs...

Page 39: ...Technical data...

Page 70: ...Description...

Page 82: ...Operation...

Page 93: ...Attachments...

Page 101: ...Rescue towing lashing lifting by crane...

Page 110: ...Maintenance...

Page 130: ...Malfunctions causes and remedies...

Page 133: ...Protection against theft...

Page 136: ...Appendices...