23

GB

Machine use: basic rules

Ensure that all machine parts and equipment work properly during machine use.

Remember: the majority of inconveniences and breakdowns that occur during machine

use are caused by loosening of machine components and leaks that have not been dealt

with quickly enough.

Since running in produces a general settling of all mechanical components and hydraulic

connections, highly rigorous machine checks

ARE ESSENTIAL

.

Bear in mind the following regulations:

- During initial machine manoeuvres do not rev the engine too high (1,200 - 1,500

r.p.m.) so that transmission oil (converter, inverter, gears, pinion set, governors) and

hydraulic oil reach operating temperature gradually.

- Move all the levers gently to avoid damaging loads and knocks.

- Do not insist in using the hydraulic cylinders if they are unable to oppose the necessary

resistance: this, in fact, opens the main hydraulic valve and could lead to dangerous oil

overheating.

- Periodically check the warning lights and panels: If a warning light comes on or if an

indicator exceeds the allowed limits stop the vehicle immediately and switch off the

diesel engine to carry out the necessary checks. If the cause is not found do not restart

work since highly expensive components could be damaged. Wait until authorised service

personnel have carried out repairs.

- Spinning the wheels not only transmits just a fraction of engine power, but rapidly

wears down tire tread.

- The working load bucket must be in the right position. An arm indicator, which helps

position the bucket horizontally on the ground, has been installed for this purpose.

-

To ensure maximum bucket efficiency, just follow the above rules: forcing the

machine beyond its own performance levels is unnecessary and ineffectual.

Use the vehicle with the bucket down as much as possible. This position

improves machine stability and gives better visibility. If the vehicle must

be moved with a full bucket over uneven or slippery ground, drive slowly.

If this basic safety rule is ignored you could lose control of the vehicle and

cause it to roll.

When towing the vehicle, the hydraulic motor

works as a pump and via the high pressure

system valve delivers sufficient oil to protect

the system.

Bear in mind the following during towing:

1) maintain adequate towing speed (e.g. 1 km/h);

2) limit towing to short distances (1-2 km);

3) avoid the overheating of the hydraulic motor

(at approx.80°)

4) return the valve part to its original position

after towing.

Always switch on the emergency lights and the rotating light during towing.

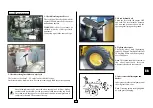

TOWING

Towing pin

Towing is a delicate operation performed at the operator’s risk. The

Manufacturer declines all liability for damage and accident that may occur.

The vehicle must be towed very slowly over flat and horizontal terrain for

short distances only and only when absolutely necessary.

Towing must be absolutely performed with the use of the tow bar.

Towing procedure

In case of the repair or malfunction of the vehicle, disable the hydrostatic pump’s high

pressure valve (see photo) by rotating the part of the valve indicated in the photo by

approximately one and a half turns.