34

GB

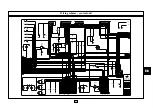

6. Lubricate central joint

Inject grease (via the special pump) until

the old grease flows out.

Note

: Greasing points are highlighted

by a red protection plug.

every

50

working hours

7. Lubricate cardan joints between engine reducer gear and differentials

Inject grease (via the special pump) until the old grease flows out.

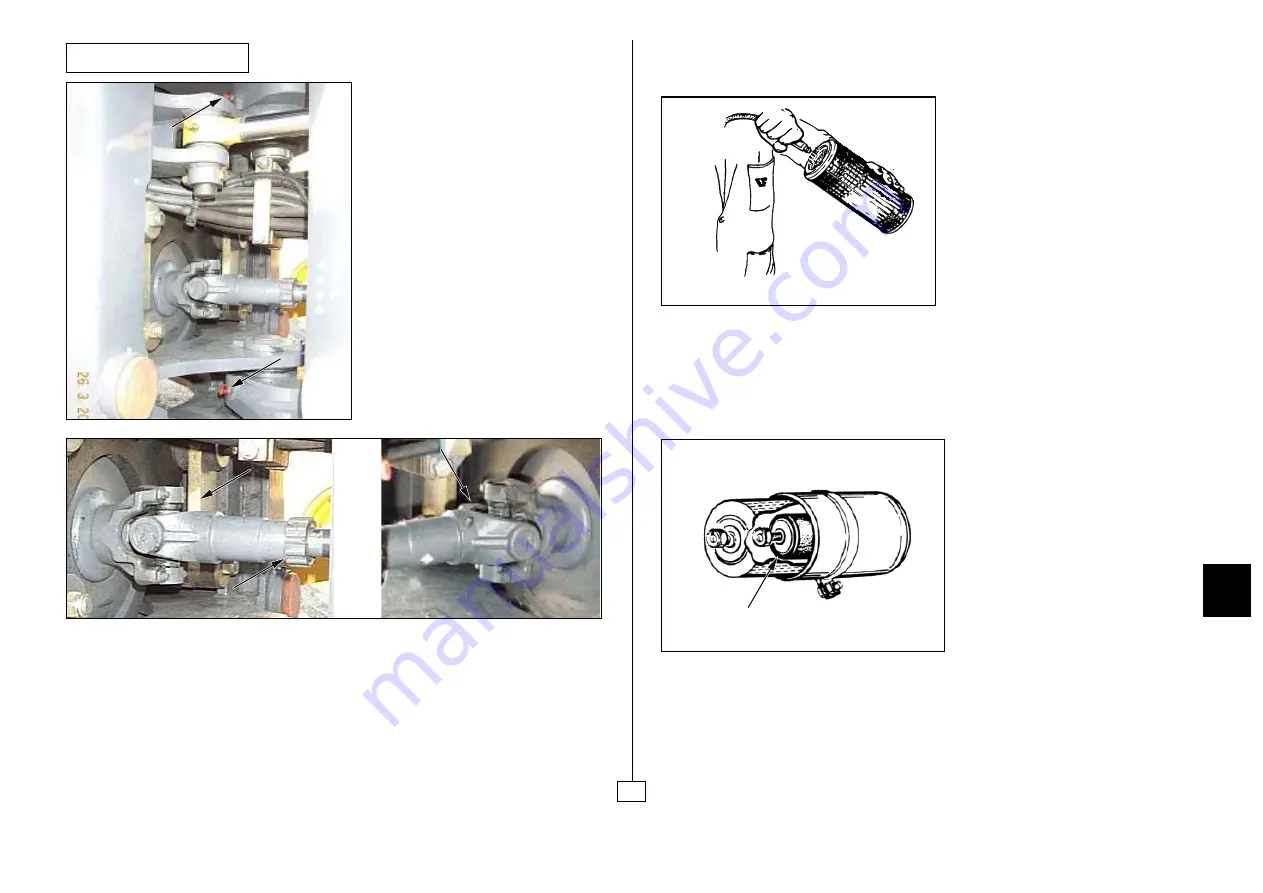

8. Check dry air filter

Main Filter

Dismantle the cartridge and clean with

dry air at a maximum pressure of 7 kg/

cm2. Direct the air from the interior

towards the exterior. Pass the jet over

the filter in line with the grill flaps at a

distance of 3 cm.

Before replacing the cartridge carry out

the following checks:

a) Check the plastic flaps for wear.

Replace the seals if damaged.

b) Check the condition of the cartridge by inserting a light inside. This will reveal any

holes: replace if there are any.

c) Check the hoses between filter and engine.

Note

: Change the cartridge every 10 cleanings or once a year.

Secondary Filter (on request)

This filter works as a protection filter

should main filter be damaged.

Replace the secondary filter if required.

Do not perform any cleaning.

Replace the secondary filter after 3

main filter replacements or after 2,000

working hours.

Never remove the secondary filter.

Remove it only in case of replacement.

DIS016