9.1 9.2

9.1

8.3/8.4

9.1 7,1 5.4

2.1/2.2/2.5/2.6/3.1/8.1/8.2 4.1 4.2

3.2

5.1/5.2/5.3

4.1

4.2

2.3/2.4/2.5/2.6/3.1

1.1/1.2/1.3

8-1

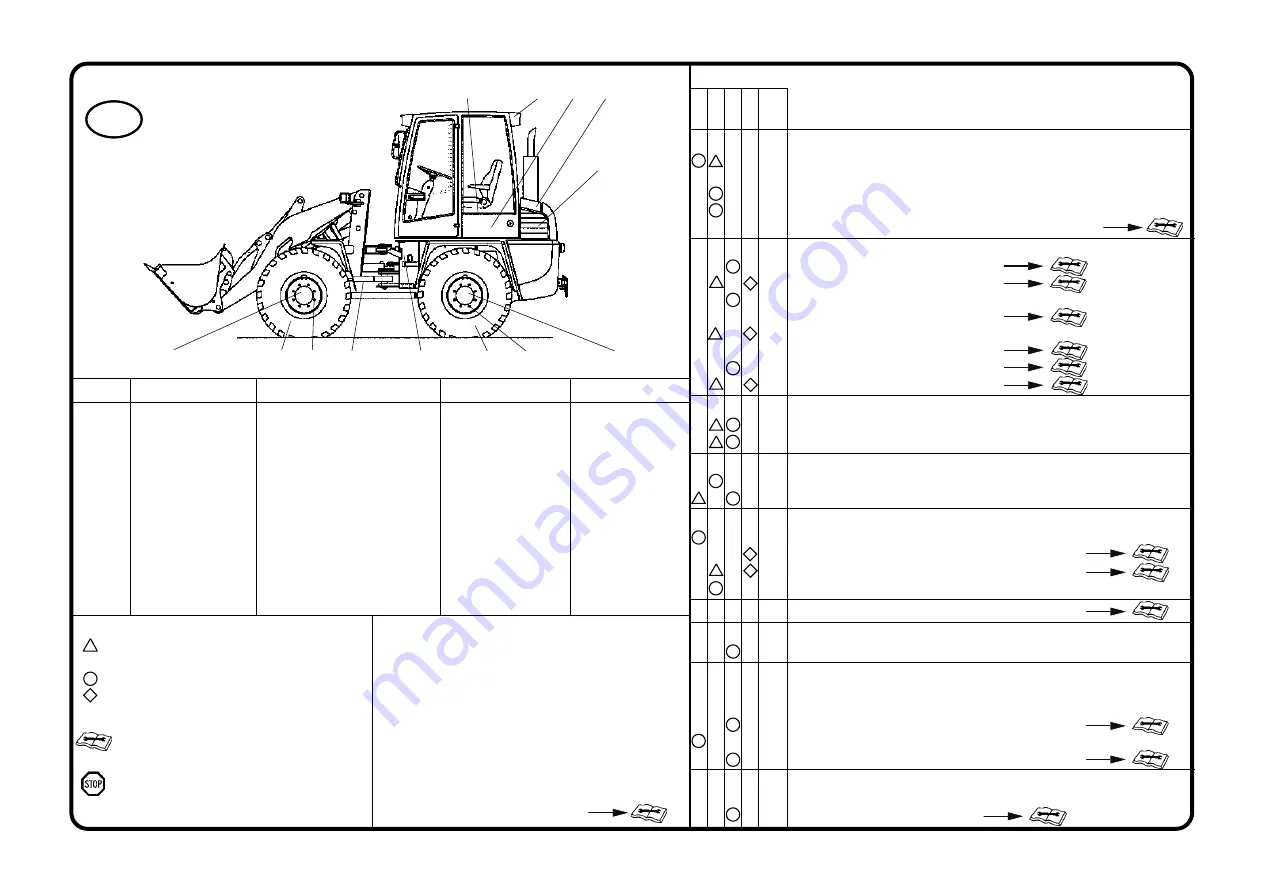

K65C/K75C/K95C

Maintenance points

1

Engine

1.1 Maintenance according to manufacturer's regulations

1.2 Dry air filter system

Activate dust removal valve

Check maintenance display

1.3 Replace filter element if maintenance display is red

2

Axles / distribution gear

2.1 Check oil level in front axle

2.2 Change oil in front axle

2.3 Check oil level in rear axle with

distribution gear

2.4 Change oil in rear axle with

distribution gear

2.5 Check oil level in planetary gear

2.6 Change oil in planetary gear

3

Axles / cardan shaft / articulated pendulum joint

3.1 Check fastening of axles (385 Nm)

3.2 Check fastening of cardan shaft (49 Nm)

4

Wheels and tires

4.1 Check air pressure

4.2 Check fastening of wheel nuts (440 Nm)

5

Hydraulic system

5.1 Oil level check (view glass)

5.2 Oil change

5.3 Replace filter inserts, observe electr. control lamp

5.4 Check and clean hydraulic oil cooler

6

Lubrication points (indicated in red)

7

Battery

7.1 Visual check

8

Brake system

8.1 Service and parking brake:

functional and visual check before starting work

8.2 Service brake: check brake lining, adjust if necessary

8.3 Service brake: visually check compensation reservoir

8.4 Parking brake: check brake lining, adjust if necessary

9

Lighting system / fresh air filter

9.1 Functional check before starting work

9.2 Check fresh air filter

*

*

*

*

*

*

*

GB

Item Designation

Specification

Viscosity

Amount

1 Motor oil

MIL-L-2104 C = API-CD

acc. to manufacturer ca. 10 l with oil lfilter

2.2 Gear oil

MIL-L-2105 D = API-GL5-6-LS SAE 85 W 90-LS

ca. 7.7 l

with LS additive

2.4 Gear oil

MIL-L-2105 D = API-GL5-6-LS SAE 85 W 90

ca. 8.0 l (20 km/h)

with LS additive

ca. 9.5 l (30 km/h)

2.6 Gear oil

MIL-L-2105 D = API-GL5-6

SAE 85 W 90

ca. 2 x 0.7 l each

5.2 Hydraulic oil

DIN 51524 - HVLP 46

ISO VG 46, VI > 180 ca. 100 l

6 Multi-purpose grease DIN 51825 - K2K

as required

7 Distilled water

as required

8 Brake fluid

DIN 51524 - HVLP 46

ISO VG 46, VI > 180 as required

Key to symbols

First oil change, first filter replacement

or first check

Check; eliminate any determined problems

Change

The marks / the filling and checking screws

are binding

See the operating instructions

Caution

When carrying out maintenance work, heed

the accident prevention regulations!

Lubrication points (indicated in red)

Lubricate glide points as required and always

after cleaning using multi-purpose grease acc. to

DIN 51825 KSK.

Oil lubrication points

Lubricate joints and toggle levers every

50 operating hours with engine oil MIL-L-2104 C.

Optional equipment: biodegradable hydraulic oil

Ester-based synthetic hydraulic oil,

viscosity class ISO VG 46 VI > 180

10 50 500

1500

Item

Every x operating hours

max. permissible intervals or

shorter (depending on use)

4102945A

8

Maintenance Plan

Summary of Contents for AL 65

Page 8: ...Safety regulations...

Page 29: ...Signs...

Page 38: ...Technical data...

Page 60: ...Description...

Page 72: ...Operation...

Page 83: ...Attachments...

Page 91: ...Rescue towing lashing lifting by crane...

Page 100: ...Maintenance...

Page 120: ...Malfunctions causes and remedies...

Page 123: ...Protection against theft...

Page 126: ...Appendices...

Page 127: ......

Page 128: ......

Page 131: ......

Page 134: ...K65C K75C K95C K65C K75C K95C B B...

Page 135: ...K65C K75C K95C K65C K75C K95C C C...

Page 136: ...K65C K75C K95C K65C K75C K95C D D...

Page 137: ...K65C K75C K95C K65C K75C K95C E E...

Page 138: ...K65C K75C K95C K65C K75C K95C F F...