7.1

12.2

12.1

11.2

12.1

8.1/8.2/8.3/8.4

3.1/3.2/3.3/3.4/5.1/11.1

6.1

6.2 5.2 10.1 4.1/4.2 5.2

6.1

6.2

2.1/2.2/2.3/2.4/5.1/11.1

1.1/1.2/1.3/1.4/1.5

12.1

GB

.11.2002

Senff

neu)

4184997A

S152.S20.09.00.019

4184997A

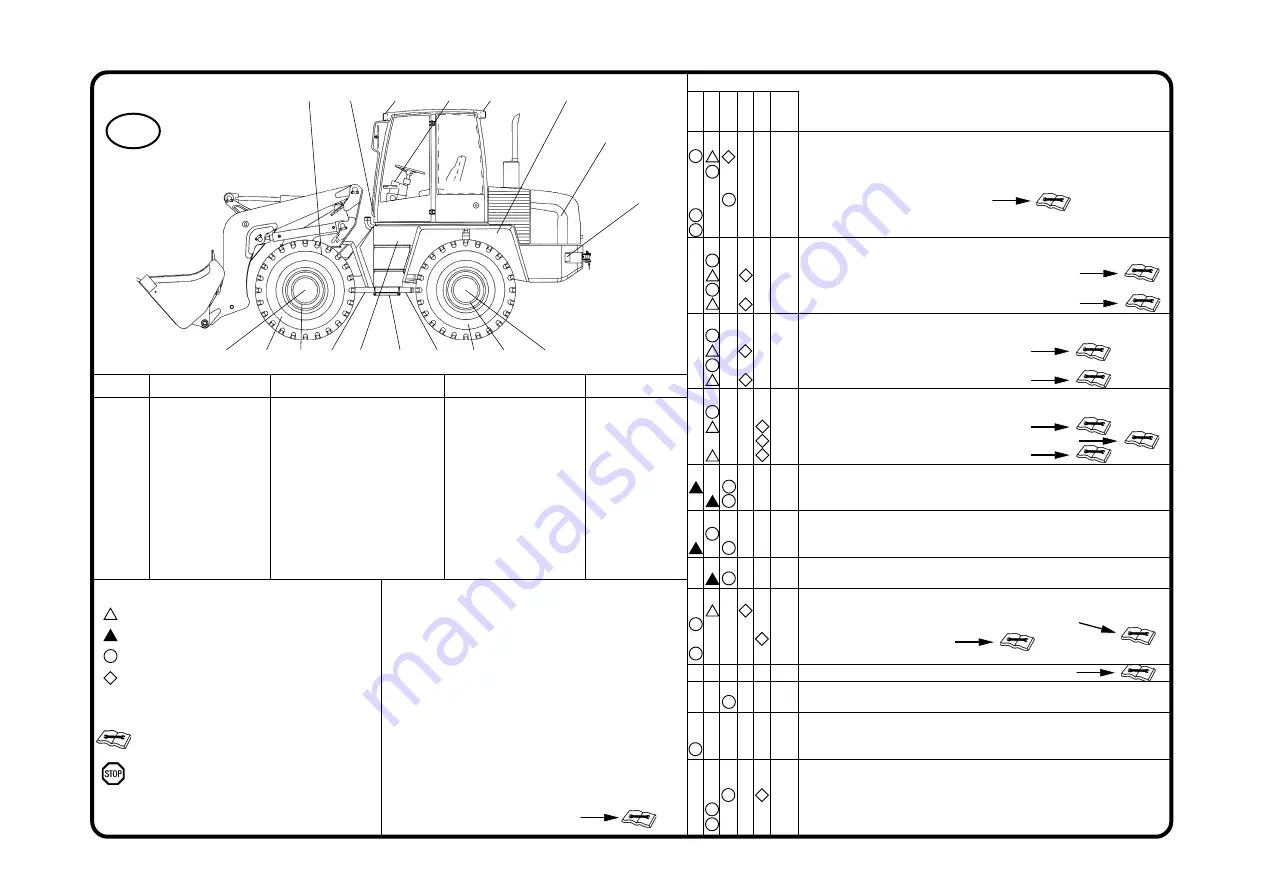

Maintenance Points

1

Engine

1.1

Maintenance according to manufacturers specs

1.2

Dry air filter unit: Check service display

Change filter element if display shows red

1.3

Check and clean fuel filter

1.4

Check coolant fill-level

1.5

Check and clean combined cooling unit

2

Rear axle

2.1

Check oil fill-level of transmission unit (inspection screw)

2.2

Oil change transmission unit

2.3

Check oil fill-level of helical planetary gearing (inspection screw)

2.4

Oil change helical planetary gearing

3

Front axle

3.1

Check oil fill-level of transmission unit (inspection screw)

3.2

Oil change transmission unit

3.3

Check oil fill-level of helical planetary gearing (inspection screw)

3.4

Oil change helical planetary gearing

4

Transfer Case

4.1

Check oil fill-level of transfer case (inspection screw)

4.2

Oil change transfer case

4.3

Change transfer case oil filter insert (fine filter)

4.4

Clean transfer case suction filter (pre-filter)

5

Axles / Articulated Shafts

5.1

Check tightness of axles (500 Nm)

5.2

Check tightness of articulated shafts (65 Nm)

6

Wheels and Tyres

6.1

Check air pressure

6.2

Check tightness of wheel bolts (600 Nm)

7

Swivel Joint

7.1

Check tightness (610 Nm)

8

Hydraulic Unit

8.1

Change suction return line filter insert, check electr. display

8.2

Check oil fill-level (inspection glass)

8.3

Oil change

8.4

Check and clean hydraulic oil cooler

9

Greasing points (marked in red)

10

Battery

10.1 Visual check

11

Brakes

11.1 Perform visual and functional check of brakes and parking brakes before starting work

11.2 Check accumulator valve

12

Lighting unit / Air filter / Air conditioning unit

12.1 Perform functional check before starting work

12.2 Check air filter

12.3 Check condensator for contamination

12.4 Check tension of compressor drive belt

Item

Name

Specification

Viscosity

Quantity

1

Engine Oil

MIL-L-2104 C = API-CD

SAE 15 W 40

= 10 l with Oil filter

2.2

Transm. Oil with LS Add. MIL-L-2105 B = API-GL5-6-LS

SAE 85 W 90-LS

= 12,8 l

2.4

Transm. Oil with LS Add. MIL-L-2105 B = API-GL5-6-LS

SAE 85 W 90-LS

= 2 x 1,9 l

3.2

Transm. Oil with LS Add. MIL-L-2105 B = API-GL5-6-LS

SAE 85 W 90-LS

= 15,0 l

3.4

Transm. Oil with LS Add. MIL-L-2105 B = API-GL5-6-LS

SAE 85 W 90-LS

= 2 x 1,9 l

4.2

Transmission OIl

General Motors ATF Typ DEXRON II ATF 22 SAE 75 W

= 6,0 l

8.3

Hydraulic Oil (4.)

DIN 51524 - HVLP 46

ISO VG 46, VI > 180 = 160 l

9

Grease

DIN 51825 - KPF 1/2 N-20

as required

10

Distilled water

as required

12

Coolant

R 134 a

850 g ± 50 g

Lubrication Points (marked in red)

1. Grease bolts with DIN 51825 - KPF 1/2 N-20

every 10 hours.

2. Grease friction points as required and after

cleaning with DIN 51825 - KPF 1/2 N-20.

Oil Lubrication Points

3. Oil joints and bell cranks every 50 working

hours with engine oil MIL-L-2104 C

Biodegradable Hydraulic Oil

4. Synthetic ester based hydraulic oil viscosity

class ISO VG 46 VI > 180

Intervals in working hours

max. permissible intervals,

can be shorter dep. on use

*

*

*

*

*

*

*

10

100

500

750

1500

Pos.

Legend

First oil or filter change

First service interval, repair any failures noted

Service, repair any failures noted

Change

these marks, filling or service points are

mandatory:

Refer to manual

Attention

Observe accident prevention measures

when performing servicing tasks!

*

8

Maintenance (Maintenance Plan AS 150 Type 40 km/h)

8-1

S152/Z152

Summary of Contents for AS 150

Page 7: ...Safety regulations ...

Page 19: ...Signs ...

Page 22: ...Anti TheftProtection ...

Page 25: ...Description ...

Page 34: ...Operations ...

Page 46: ...Attachments ...

Page 54: ...Rescue Towing Lashing Crane Lifting ...

Page 61: ...Maintenance ...

Page 80: ...Troubleshooting ...

Page 83: ...Wiring and Hydraulics ...

Page 98: ...Technical Data Equipment ...

Page 103: ...Technical Data Attachments ...

Page 112: ...Optional Extras Changes ...