S150/S151/S152/Z152

8-17

Maintenance

8

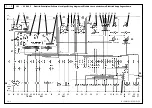

8.3.4 Swivel assembly (8-39/arrows)

The grease pack is designed to avoid friction, to seal the

unit and protect it from corrosion. For this reason, the

bearings should be greased liberally

every 10 operating

hours

until grease emerges. When greasing the swivel

assembly rotate the loader arm in 20° steps. Ensure that

all four grease points are greased at every step. Additionally

grease the assembly before and after longer periods of

inactivity.

DANGER

-

Before greasing, mechanically prop up the

bucket arm [e.g. by inserting the bucket arm

support (option) (1-1/arrow)], apply the parking

brake (4-7/4) and set the drive direction switch

(4-7/3) to “0“.

-

Makes sure that nobody is in the working

area of the loader arm

while

rotating the arm.

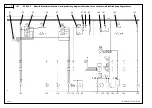

8.3.5 Loader assembly

ATTENTION

The bolts/greasing points (8-40/arrows of the

loader/quick coupler assembly) must be greased

every 10 operating hours

.

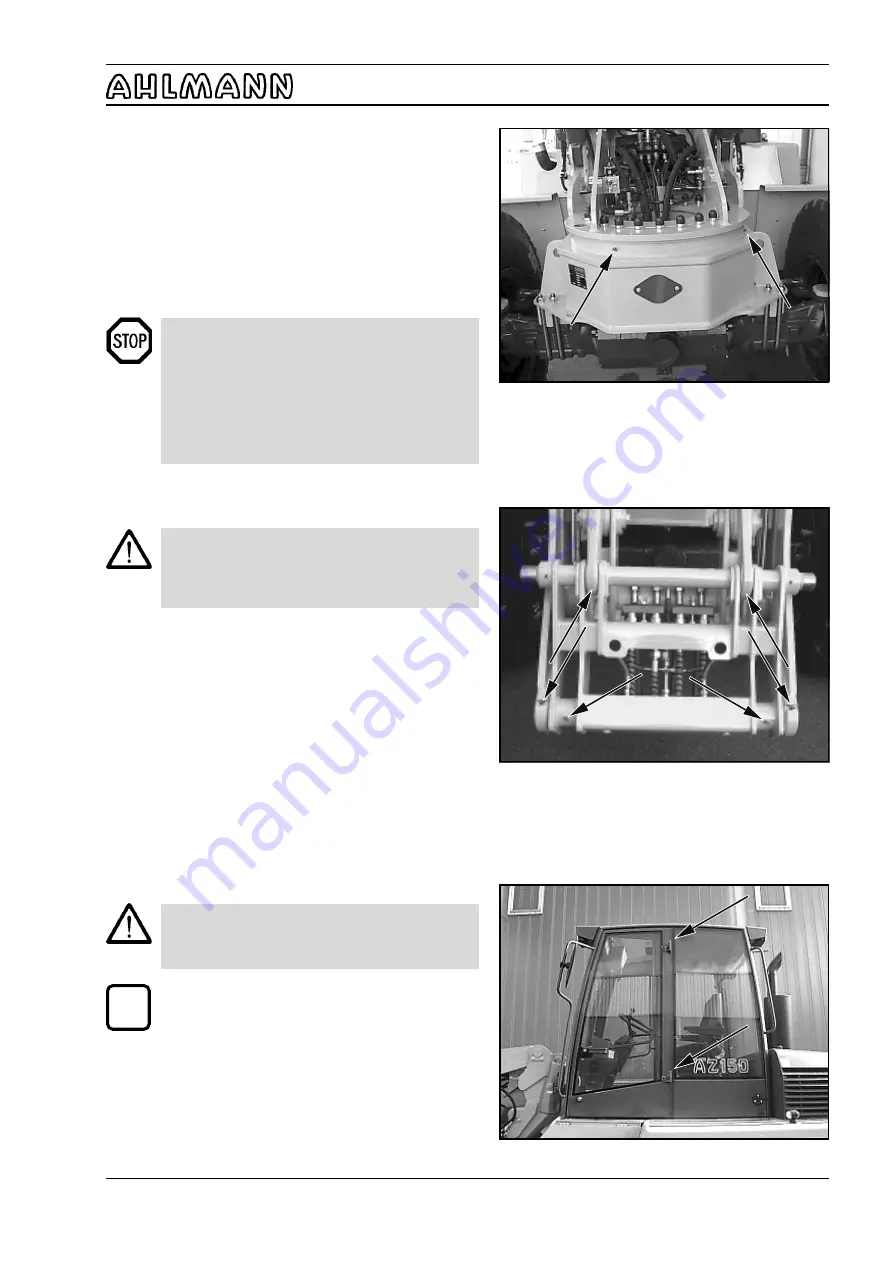

8.3.6 Driver cab doors (8-41/arrows)

ATTENTION

Ensure that the hinges of the driver cab doors are

greased

every 50 operating hours

.

NOTE

Ensure that the hinges on both driver cab doors

are greased.

Fig. 8-39

Fig. 8-40

Fig. 8-41

i

Summary of Contents for AS 150

Page 7: ...Safety regulations ...

Page 19: ...Signs ...

Page 22: ...Anti TheftProtection ...

Page 25: ...Description ...

Page 34: ...Operations ...

Page 46: ...Attachments ...

Page 54: ...Rescue Towing Lashing Crane Lifting ...

Page 61: ...Maintenance ...

Page 80: ...Troubleshooting ...

Page 83: ...Wiring and Hydraulics ...

Page 98: ...Technical Data Equipment ...

Page 103: ...Technical Data Attachments ...

Page 112: ...Optional Extras Changes ...