S220/S221/S230/S231/Z200

6-4

6

Attachments

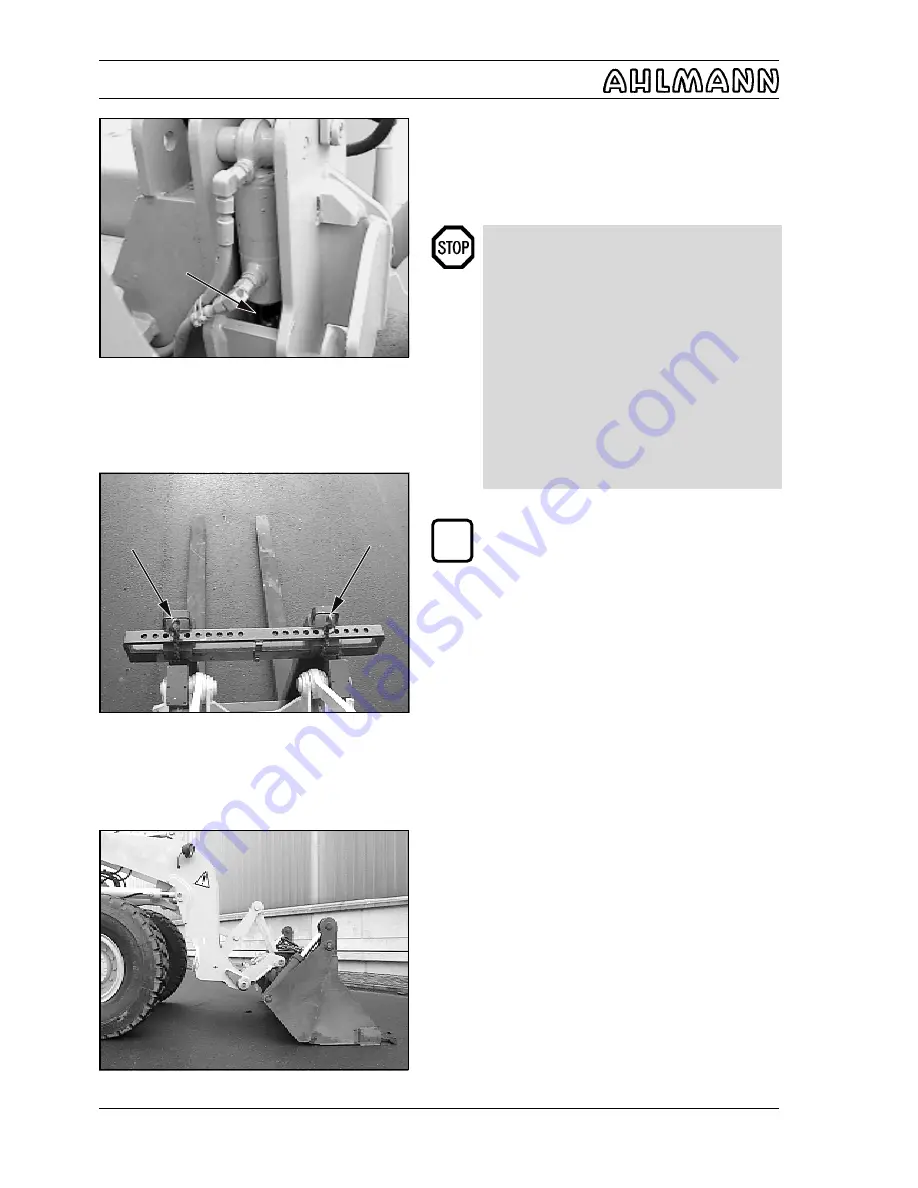

Figure 6-7

Figure 6-9

Figure 6-8

6.2.2 Fork-lift attachment

NOTE

Mounting and dismounting are carried out in the same way

as for the standard/lightweight bucket (section 6.2.1).

DANGER

-

The fork-lift attachment is mounted and locked

correctly when it is located next to the quick-

change device and the piston rods of the

quick-change device cylinder can be plainly

seen (6-7/arrow).

-

Position both fork tines at an equal distance

from the centre (6-8/arrows) and secure them

with socket pins.

-

Distribute the load equally on both fork tines

and secure it against moving and falling off.

-

Let the load rest against the rear of the fork

and tilt the fork-lift attachment.

NOTE

The type plate is on the rear of the upper fork

carrier.

6.3

Mounting and dismounting attach-

ments with hydraulic connections to loaders

with claw locks (optional equipment)

6.3.1 Multi-purpose bucket

Mounting

(1) Bring the bucket arm to its lowest position and tip the

quick-change device.

(2) Drive the loader up to the bucket (6-9).

(3) Press and hold the release button for the quick-

change device (4-7/1).

i

Summary of Contents for AS 210

Page 7: ...Safety Regulations ...

Page 19: ...Signs ...

Page 22: ...ProtectionAgainstTheft ...

Page 25: ...Description ...

Page 33: ...Operation ...

Page 44: ...Attachments ...

Page 53: ...Rescue Towing Lashing Lifting by Crane ...

Page 60: ...Maintenance ...

Page 78: ...Faults Causes and Remedies ...

Page 81: ...Diagrams ...

Page 98: ...Technical Data Loader ...

Page 102: ...Technical Data Attachments ...

Page 115: ...AdditionalOptions Modifications Notes on Inspection for Loaders ...