Electrical Connections

Refer to the unit rating plate below the control panel for

precise power requirements for your unit, and for

ampacity and over-current protection requirements.

All wiring must be in accordance with the National

Electrical Code, NFPA No. 70, latest edition, and all

applicable state and local codes. Wiring diagrams are

located on pages 44 and 45.

• Locate the equipment disconnect means within 3

feet of the heater’s electrical enclosure, or as

close to the heater as possible. Always satisfy

applicable codes and standards.

• In sizing power wiring, be especially aware of up-

sizing requirements necessary due to wiring

distances. Always satisfy applicable codes and

standards.

• Electrical installation should be done by a licensed

electrician only.

Model

No.

Power

Min.

Circuit

Ampacity

Breaker Size (A)

Recommended Wire Length from

Breaker to Heater*

MIN.

MAX.

10 AWG 8 AWG

6 AWG

4 AWG

5450

208/230-1-60

30

50

60

94 ft

151 ft

239 ft

383 ft

6450

208/230-1-60

29

50

60

97 ft

156 ft

247 ft

396 ft

6453

208/230-3-60

26

35

40

109 ft

174 ft

276 ft

442 ft

8450

208/230-1-60

41

50

60

NR

110 ft

175 ft

280 ft

8453

208/230-3-60

34

40

50

83 ft

133 ft

211 ft

338 ft

* Reference only - see National Electric Code or local codes for wire gauge length limits.

Table A: Typical System Electrical Power Requirements

9

NOTE:

Refer to the National Electrical Code, Article

680, for general requirements for swimming pools

and equipment, and to Article 440 for special consid-

erations necessary for circuits supplying hermetic

refrigeration motor/compressors.

WARNING:

This unit MUST be installed using flex-

ible conduit for supply wiring to the unit. This will

allow movement of the conduit whenever the junc-

tion box is removed for service - see instructions on

page 38.

This unit is pre-wired to work with external control sys-

tems, heat-on-demand options and other external time

clock overrides. Refer to the external control system’s

instructions, and page 29 of this manual, for installa-

tion information.

An earth ground lug is located to the right side of the

water connections.

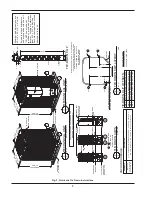

Water Connections

1. Connect the heat pump pool heater in the return

water line between the filter and the pool/spa. See

the

Plumbing Diagrams

beginning on page 40.

2. Connect the filter outlet to the fitting marked

INLET/ENTREE

at the bottom front of the unit.

3. Connect the fitting marked

OUTLET/SORTIE

to

the return piping to the pool/spa. Unit inlet/outlet

connection fittings are 2-inch PVC unions.

CAUTION:

The heat pump pool heater inlet and

outlet connections are

NOT

interchangeable. They

must be connected as instructed below.

NOTE:

The earth ground lug may be relocated to

the left side of the water connections as needed dur-

ing unit installation.

WARNING:

Improper installation of any type of

automatic chemical feeders can result in serious

damage to, or premature failure of, the heat

pump pool heater and may void the heat pump

pool heater warranty.

Install a check valve and/or a

Hartford loop AFTER the heat pump pool heater and

BEFORE any chlorinating devices. Install any auto-

matic chemical feeders AFTER the heat pump pool

heater.