8

RC SERIES INSTALLATION MANUAL

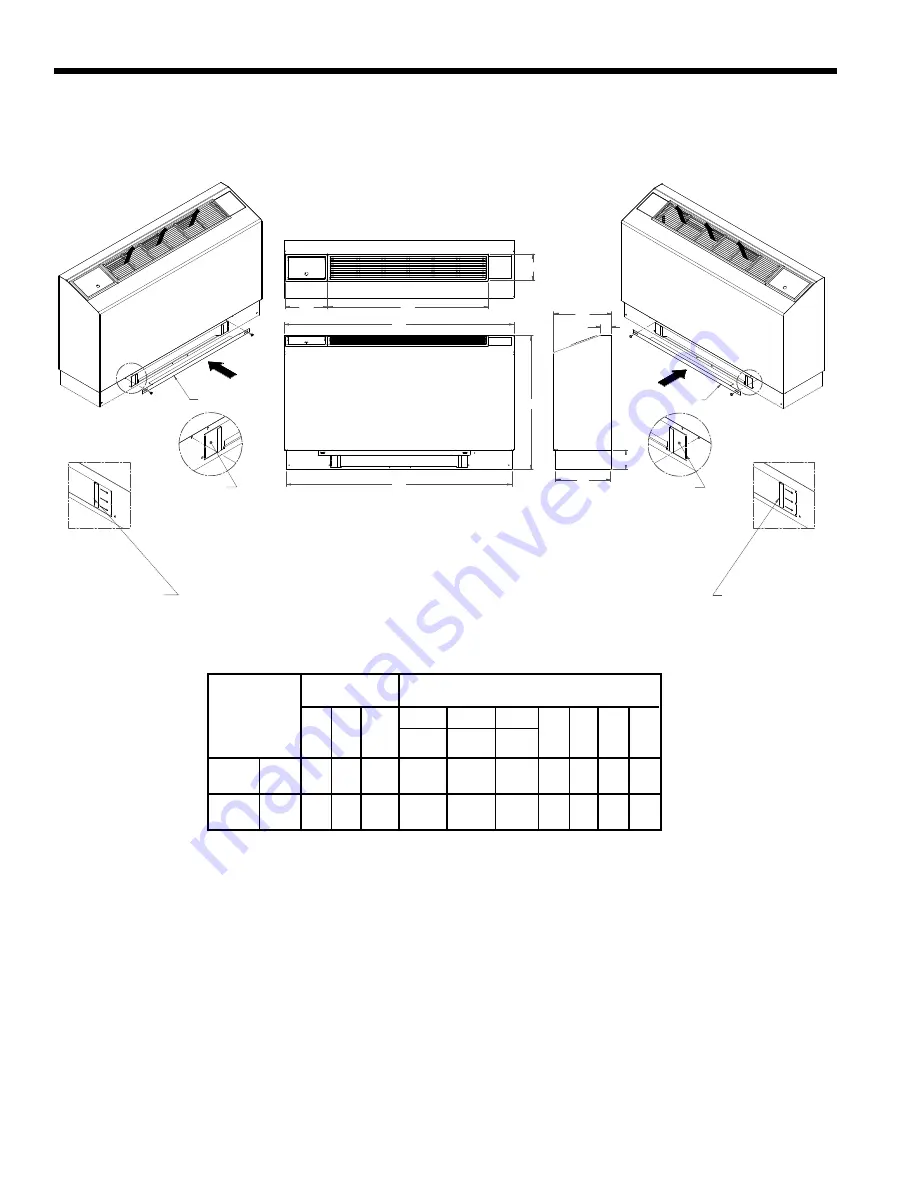

RCE09-18

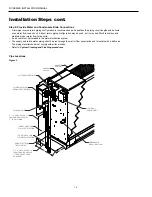

REMOVE PLASTIC STRIP

FROM BROKEN TAB AND

REPLACE ON BROKEN

EDGE OF LEG AS SHOWN

Overall Cabinet

Ext. Slope Top

Configuration

A

B

C

D

E

F

G

H

I

J

Width Depth Height Grille Lid

Grille

Length

Grille

Width

in.

50.0 12.6 29.1

9.2

35.0

6.1

2.4 49.1 12.0 4.3

cm. 127.0 32.0 73.9

23.4

88.9

15.6

6.1 124.7 30.5 10.9

in.

55.0 12.6 29.1

9.2

35.0

6.1

2.5 54.1 11.8 4.3

cm. 139.7 32.0 73.9

23.4

88.9

15.6

6.4 137.4 29.8 10.9

09-12

15-18

FILTER BRACKET

FILTER BRACKET

A

D

E

C

H

I

J

F

B

G

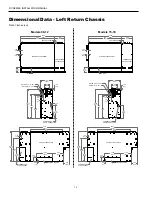

A

B

RIGHT RETURN

TOP

FRONT

LEFT RETURN

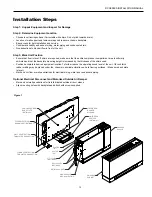

DETAIL B

TWIST EXTENDED TAB

BACK AND FORTH UNTIL

TAB BREAKS OFF

(ONLY BREAK-OFF

TAB SAME SIDE AS

GRILLE LID AS SHOWN)

DETAIL A

TWIST EXTENDED TAB

BACK AND FORTH UNTIL

TAB BREAKS OFF

(ONLY BREAK-OFF

TAB SAME SIDE AS

GRILLE LID AS SHOWN)

REMOVE PLASTIC STRIP

FROM BROKEN TAB AND

REPLACE ON BROKEN

EDGE OF LEG AS SHOWN

Dimensional Data - Extended Slope Top Cabinet