3. Splice copper wire pigtails to aluminum wire with U.L. recognized connectors for

copper-aluminum splices. Follow these instructions very carefully to make a posi-

tive and lasting connection;

a. Strip insulation from aluminum conductor.

b. Coat the stripped end of the aluminum wire with the recommended inhibitor

and wire brush aluminum surface through inhibitor. Inhibitors: Brundy, Pentex

“A”; Alcoa, No. 2EJC; T&B KPOR Shield.

c. Clean and recoat aluminum conductor with inhibitor.

d. Make the splice using the above listed wire nuts or split bolt connectors.

e. Coat the entire connection with inhibitor and wrap with electrical insulating

tape.

WARRANTY MAY NOT APPLY IF CONNECTIONS ARE NOT MADE PER INSTRUC-

TIONS

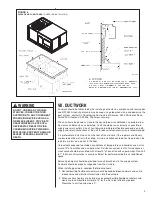

C. CONTROL WIRING (Class II)

1. Low voltage wiring should not be run in conduit with power wiring.

2. Control wiring is routed through the 7/8" hole adjacent to the compressor access

panel. Use a minimum #18 AWG thermostat wire. For wire lengths exceeding 50',

use #16 AWG thermostat wire. The low voltage wires are connected to the unit

pigtails which are supplied with the unit in the low voltage connection box located

below the unit control box.

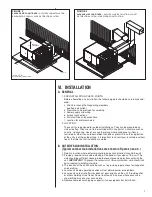

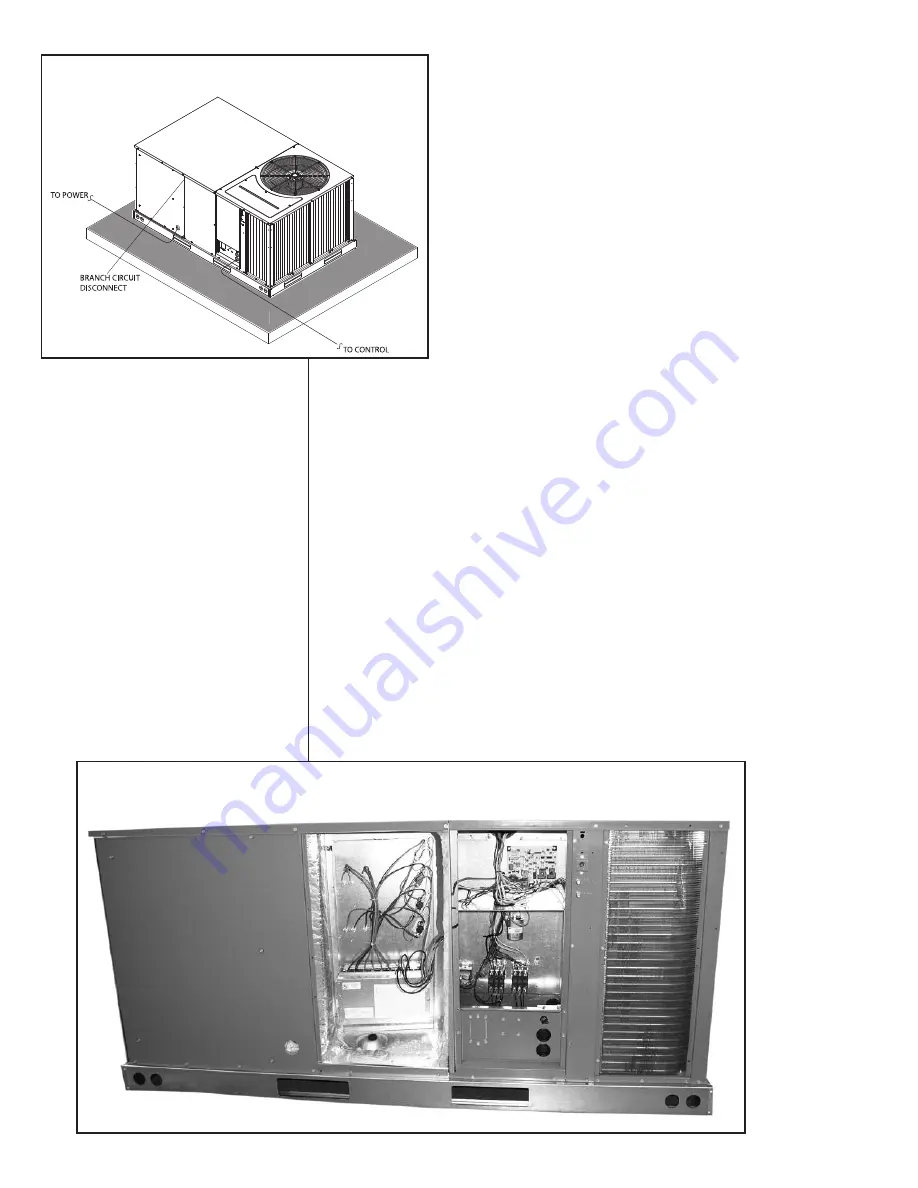

FIGURE 11

HEATER KIT INSTALLATION

FIGURE 10

RECOMMENDED LOCATION OF BRANCH CIRCUIT DISCONNECT

12

Summary of Contents for RLNL-C 13 SEER Series

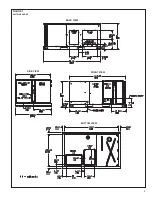

Page 5: ...5 FIGURE 1 UNIT DIMENSIONS BACK VIEW SIDE VIEW FRONT VIEW BOTTOM VIEW ...

Page 39: ...39 FIGURE 14 WIRING DIAGRAM ...

Page 41: ...3 5 TON AIR CONDITIONER 13 14 SEER 41 ...

Page 42: ...4 TON AIR CONDITIONER 13 14 SEER 42 ...

Page 43: ...5 TON AIR CONDITIONER 13 SEER 43 ...

Page 46: ...46 ...

Page 47: ...47 ...

Page 48: ...48 CM 0610 ...