2

I. TABLE OF CONTENTS

I. Table of Contents ...........................................................................2

II. Introduction.....................................................................................3

III. Checking Product Received...........................................................3

IV. Specifications .................................................................................3

A. General .....................................................................................3

B. Major Components....................................................................3

C. R-410A Refrigerant ...................................................................3

1. Specification of R-410A ........................................................3

2. Quick Reference Guide for R-410A ......................................3

3. Evaporator Coil/TXV .............................................................4

V. Equipment Protection.....................................................................4

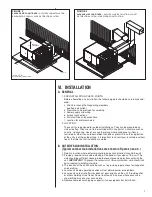

Vi. Installation ......................................................................................7

1. Pre-Installation Check Points................................................7

2. Location ................................................................................7

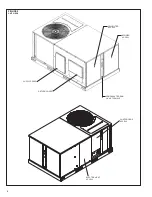

B. Outside Slab Installation ...........................................................7

C. Clearances................................................................................8

D. Rooftop Installation ...................................................................8

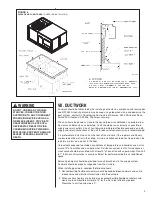

VII. Ductwork ........................................................................................9

VIII. Filters............................................................................................10

IX. Conversion Procedure..................................................................10

X. Condensate Drain ........................................................................10

XI. Electrical Wiring............................................................................11

A. Power Wiring...........................................................................11

B. Special Instructions for Power Wiring with

Aluminum Conductors.............................................................11

C. Control Wiring .........................................................................12

D. Internal Wiring.........................................................................13

E. Grounding ...............................................................................13

F. Thermostat..............................................................................13

XII. Indoor Air Flow Data.....................................................................14

XIII. Crankcase Heat............................................................................14

XIV. Pre-Start Check............................................................................14

XV. Startup..........................................................................................14

XVI. Operation......................................................................................15

XVII. Auxiliary Heat ...............................................................................15

XVIII. General Data...........................................................................16-23

XIX. Miscellaneous...............................................................................24

Electrical & Physical Data .......................................................24-27

Airflow Performance................................................................28-30

Heater Kit Characteristics .......................................................31-38

Wiring Diagram.............................................................................39

Charge Charts.........................................................................40-44

Troubleshooting............................................................................45

Summary of Contents for RLNL-C 13 SEER Series

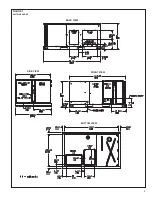

Page 5: ...5 FIGURE 1 UNIT DIMENSIONS BACK VIEW SIDE VIEW FRONT VIEW BOTTOM VIEW ...

Page 39: ...39 FIGURE 14 WIRING DIAGRAM ...

Page 41: ...3 5 TON AIR CONDITIONER 13 14 SEER 41 ...

Page 42: ...4 TON AIR CONDITIONER 13 14 SEER 42 ...

Page 43: ...5 TON AIR CONDITIONER 13 SEER 43 ...

Page 46: ...46 ...

Page 47: ...47 ...

Page 48: ...48 CM 0610 ...