----EN

EN

EN

EN----

6.2 TROUBLESHOOTING

Only qualified personnel should perform troubleshooting and or

maintenance operations.

Prior to performing any maintenance or service, be sure that:

•

no part of the machine is powered and that it cannot be connected to the mains supply.

•

no part of the machine is under pressure and that it cannot be connected to the compressed air

system.

•

Maintenance personnel have read and understand the safety and operation instructions in this

manual.

Before attempting any maintenance operation on the dryer, shut it down and wait at least 30

minutes.

Some components can reach high temperature during operation. Avoid contact until system or

component has dissipated heat.

SYMPTOM

POSSIBLE CAUSE - SUGGESTED ACTION

The dryer doesn't

start.

Verify that the system is powered.

Verify the electric wiring.

The compressor

doesn’t work.

Activation of the compressor internal thermal protection - wait for 30 minutes, then

retry.

Verify the electric wiring.

Where installed-

Replace the internal thermal protection and/or the start-up relay

and/or the start-up capacitor and/or the working capacitor.

Where installed-

The pressure switch P

A

has been activated - see specific point.

Where installed-

The pressure switch P

B

has been activated - see specific point.

Where installed-

The safety thermo-switch T

S

has been activated - see specific point.

If the compressor still doesn’t work, replace it.

The fan of the

condenser doesn’t

work.

Verify the electric wiring.

P

V

pressure switch is faulty - replace it.

There is a leak in the refrigerating fluid circuit - contact a refrigeration engineer.

If the fan still doesn't work, replace it.

AHT 75-350-

The

Aftercooler fan

doesn’t work.

Verify the electric wiring.

If the fan still doesn't work, replace it.

DewPoint too high.

The dryer doesn't start - see specific point.

The T1 DewPoint probe doesn’t correctly detect the temperature - ensure the

sensor is pushed into the bottom of copper tube immersion well.

The refrigerating compressor doesn’t work - see specific point.

The ambient temperature is too high or the room aeration is insufficient - provide

proper ventilation.

The inlet air is too hot - restore the nominal conditions.

The inlet air pressure is too low - restore the nominal conditions.

The inlet air flow rate is higher than the rate of the dryer - reduce the flow rate -

restore the normal conditions.

The condenser is dirty - clean it.

The aftercooler is dirty - clean it.

The condenser fan doesn’t work - see specific point.

The aftercooler fan doesn’t work - see specific point.

The dryer doesn’t drain the condensate - see specific point.

The hot gas by-pass valve is out of setting - contact a refrigeration engineer to

restore the nominal setting.

There is a leak in the refrigerating fluid circuit - contact a refrigeration engineer.

Summary of Contents for 20-350

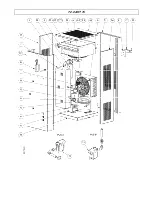

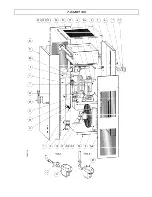

Page 29: ...7 1 1 AHT 20 50 AC 7 1 2 AHT 75 AC 7 1 3 AHT 100 150 AC ...

Page 30: ...7 1 4 AHT 200 250 AC 7 1 5 AHT 300 350 AC ...

Page 31: ...7 2 1 AHT 20 50 ...

Page 32: ...7 2 2 AHT 75 ...

Page 33: ...7 2 3 AHT 100 ...

Page 34: ...7 2 4 AHT 150 ...

Page 35: ...7 2 5 AHT 200 250 ...

Page 36: ...7 2 6 AHT 300 350 ...

Page 41: ...NOTE ...

Page 42: ...NOTE ...

Page 43: ...NOTE ...

Page 44: ...GRAMAGLIA GO ...