----EN

EN

EN

EN----

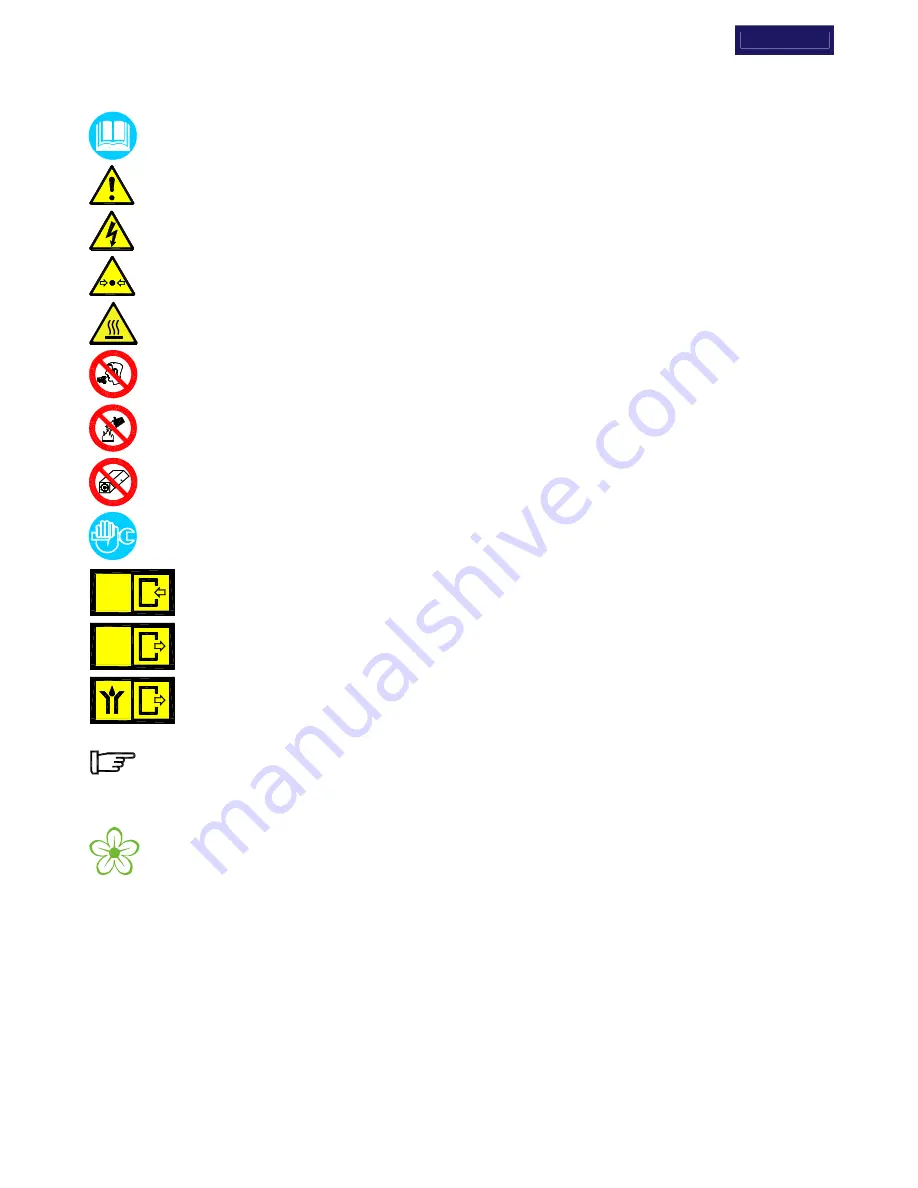

1.1 DEFINITION OF THE CONVENTIONAL SIGNS USED IN THIS MANUAL

Carefully read instruction manual before attempting any service or maintenance procedures on the

dryer.

Caution warning sign. Risk of danger or possibility of damage to equipment, if related text is not

followed properly.

Electrical hazard. Warning message indicates practices or procedures that could result in personal

injury or fatality if not followed correctly.

Danger hazard. Part or system under pressure.

Danger hazard. High temperature conditions exist during operation of system. Avoid contact until

system or component has dissipated heat.

Danger hazard. Treated air is not suitable for breathing purposes; serious injury or fatality may

result if precautions are not followed.

Danger hazard: In case of fire, use an approved fire extinguisher, water is not an acceptable

means in cases of fire.

Danger hazard. Do not operate equipment with panels removed.

Maintenance or control operation to be performed by qualified personnel only

1

.

ARIA

AIR

LUFT

AIR

Compressed air inlet connection point.

ARIA

AIR

LUFT

AIR

Compressed air outlet connection point.

Condensate drain connection point.

Operations which can be performed by the operator of the machine, if qualified

1

.

NOTE :

Text that specifies items of note to be taken into account does not involve safety precautions.

In designing this unit a lot of care has been devoted to environmental protection:

•

CFC free refrigerants

•

CFC free insulation parts

•

Energy saving design

•

Limited acoustic emission

•

Dryer and relevant packaging composed of recyclable materials

This symbol requests that the user heed environmental considerations and abide with suggestions

annotated with this symbol.

1

Experienced and trained personnel familiar with national and local codes, capable to perform the needed activities, identify and

avoid possible dangerous situations while handling, installing, using and servicing the machine.

Ensuring compliance to all

statutory regulations.

Summary of Contents for 20-350

Page 29: ...7 1 1 AHT 20 50 AC 7 1 2 AHT 75 AC 7 1 3 AHT 100 150 AC ...

Page 30: ...7 1 4 AHT 200 250 AC 7 1 5 AHT 300 350 AC ...

Page 31: ...7 2 1 AHT 20 50 ...

Page 32: ...7 2 2 AHT 75 ...

Page 33: ...7 2 3 AHT 100 ...

Page 34: ...7 2 4 AHT 150 ...

Page 35: ...7 2 5 AHT 200 250 ...

Page 36: ...7 2 6 AHT 300 350 ...

Page 41: ...NOTE ...

Page 42: ...NOTE ...

Page 43: ...NOTE ...

Page 44: ...GRAMAGLIA GO ...