5

5.5 Disassembly and Mounting

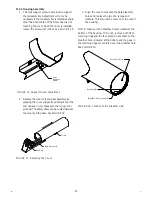

1. Detach the hardware kit from the housing.

2. Use a M7 hex wrench or socket to remove the

two M4 screws from the housing cover. Save all

hardware, which will be needed in reassembly.

See FIGURE 1.

FIGURE 1 Removing the M4 Cover Screws

3. Remove the cover from the base assembly by

grasping the cover and gently pulling forward.

Do not remove the safety cable from the cover

or the base assembly. See FIGURE 2.

FIGURE 2 Removing the Cover

4. Attach the housing to an appropriate mount or

pan/tilt. Use the instructions provided with the

mount or pan/tilt. The base assembly has three

clearance holes for mounting. Use three M6

screws and nuts or three 1/4in. screws and nuts

(not provided). Lock washers are required (not

provided). Rotating the rail assembly will allow

access to the mounting holes. This can be

accomplished by loosening the three M4 screws.

See also Camera/Lens Orientation. It will be easier

to mount the base before installing the camera,

but it may be mounted anytime during the

installation process. See FIGURE 3.

FIGURE 3 Mounting the Base Assembly

5.6 Camera/Lens Installation

Place the camera/lens combination onto the rail

assembly.

Fixed Lens Cameras

: Position the camera/lens so that

the lens is positioned over the heater but not past it.

Secure the camera to the rail assembly with the

1/4-20 x 3/8in. BHC screw, a nylon bushing, and a

0.4mm (0.016in.) plastic spacer. Place the nylon

bushing over the screw and slide both between the

rails through the front cut-out section. Slide the spacer

over the screw so it is positioned in-between the rails

and the camera. See FIGURE 4.

FIGURE 4 Mounting a Fixed Lens Camera

Base Assembly

Cover

Rail Assembly

M4 Screws

Mounting Holes

Camera

Heater

Bushing

Rails

Screw

Spacer

Lens Control Cable

Cable Type

Jacketed Multiconductor Cable

Cable Size

Outside diameter between 4.3mm

and 11.9mm (0.170in. and 0.470in.)

Cable Shape

Round

Shield

Overall shielding

Conductors

Stranded 20 to 16 AWG wire

No. of Conductors

4 and 8

Conductor Insulation

Color coded

Sources

Belden 9552

Belden 9554

M4 Screws